LTM 1450-8.1

Mobile crane

LTM 1450-8.1 - The big fast-erecting crane!

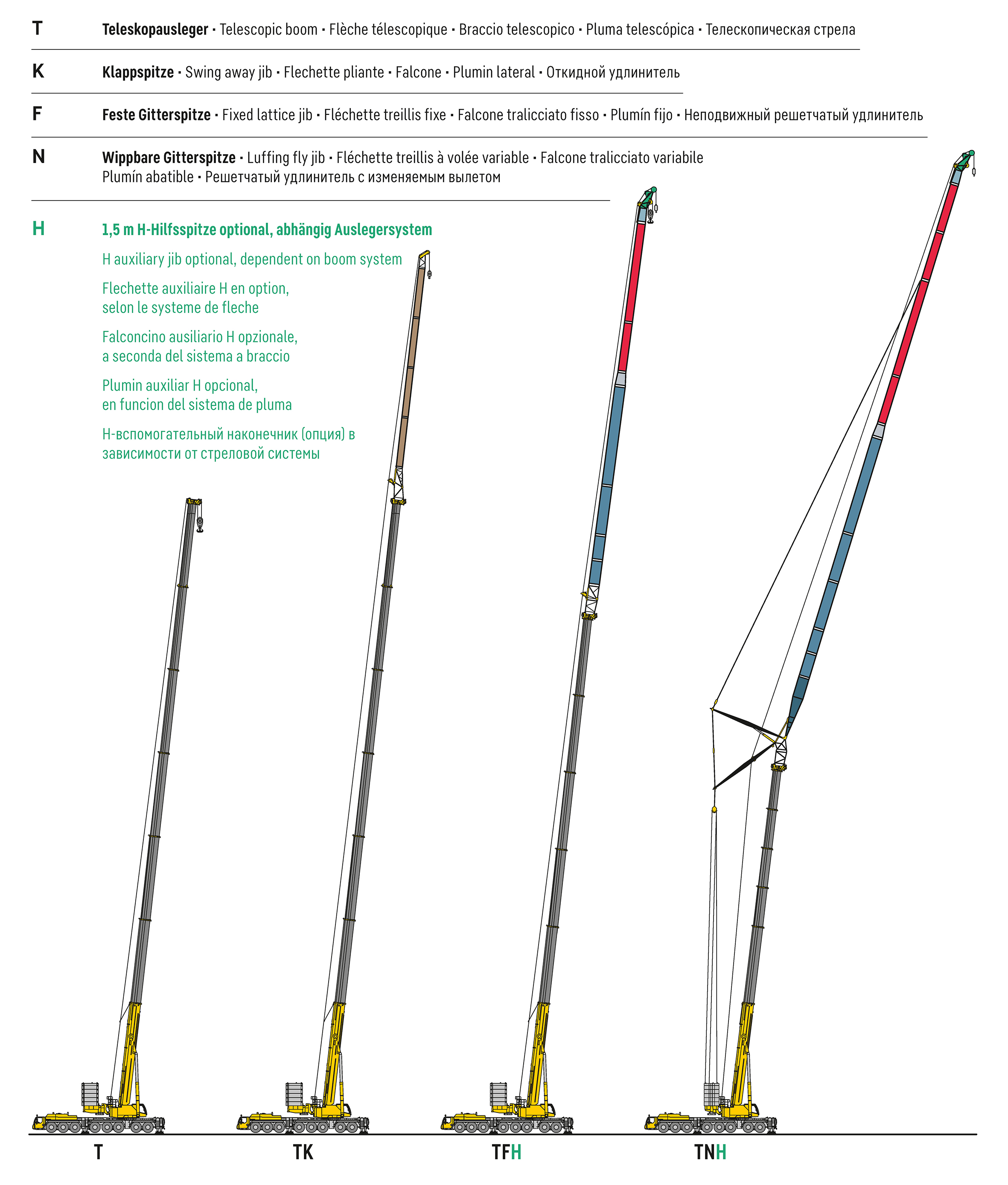

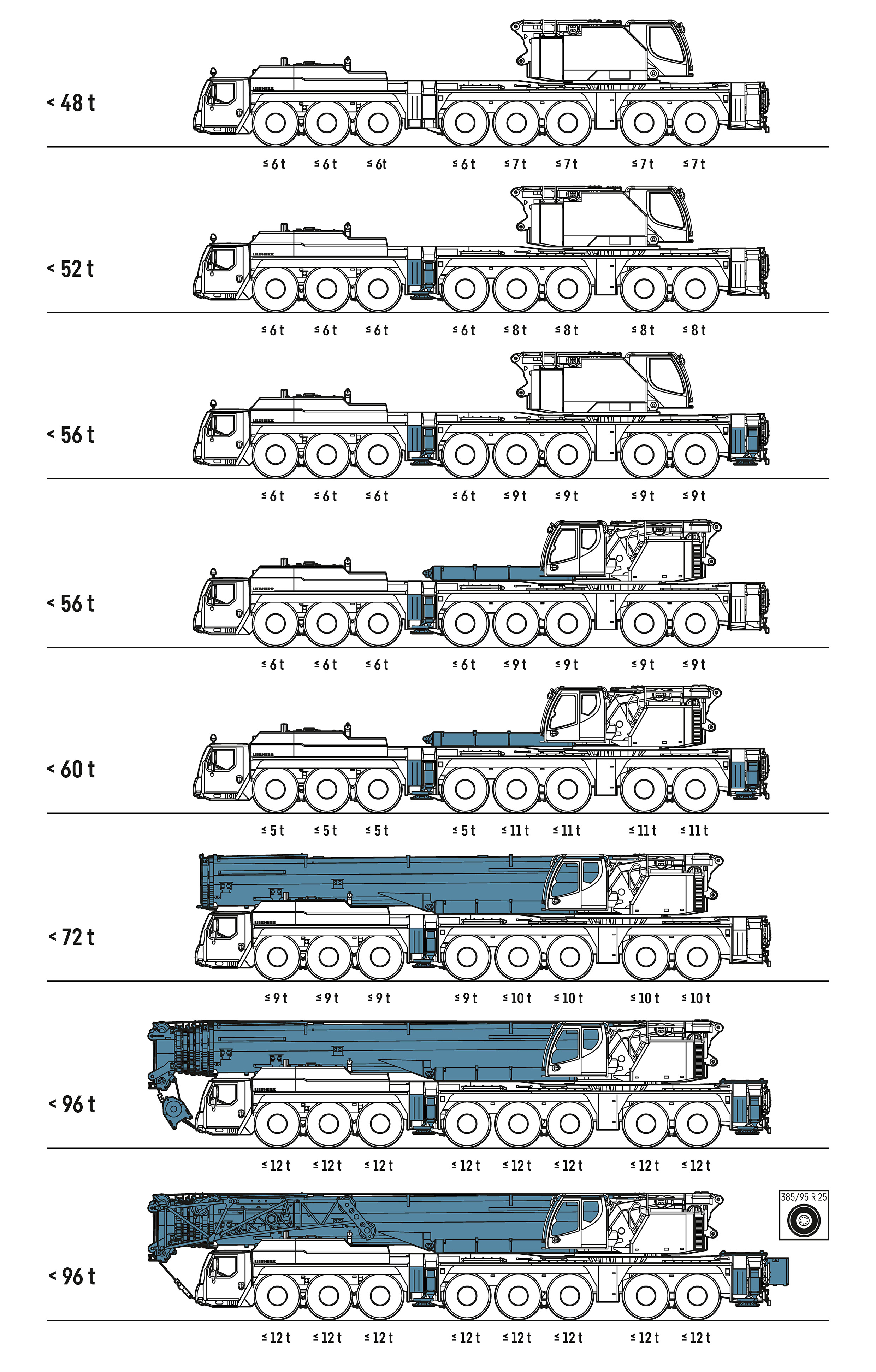

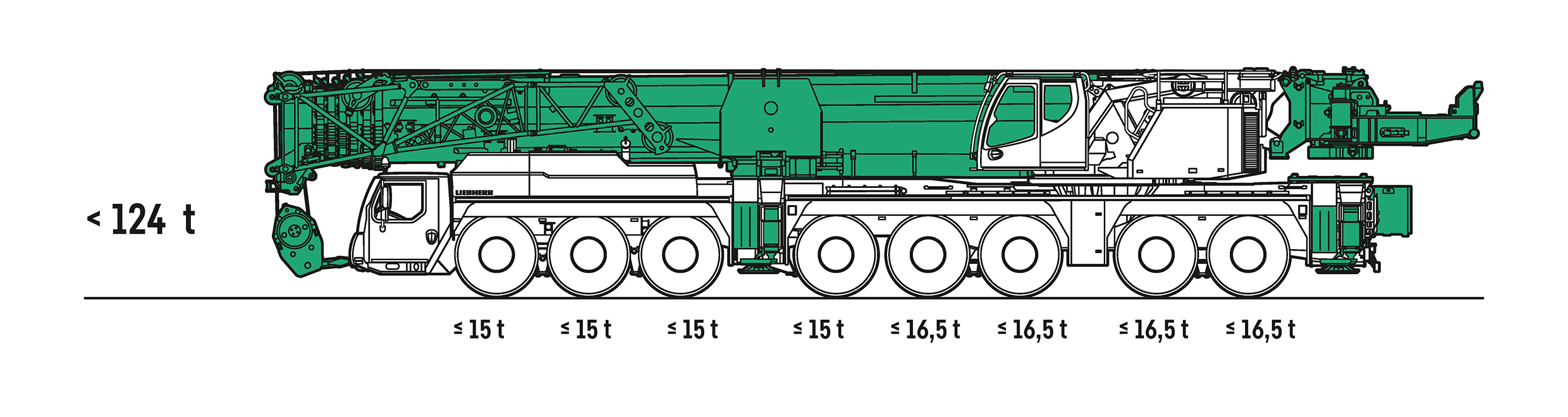

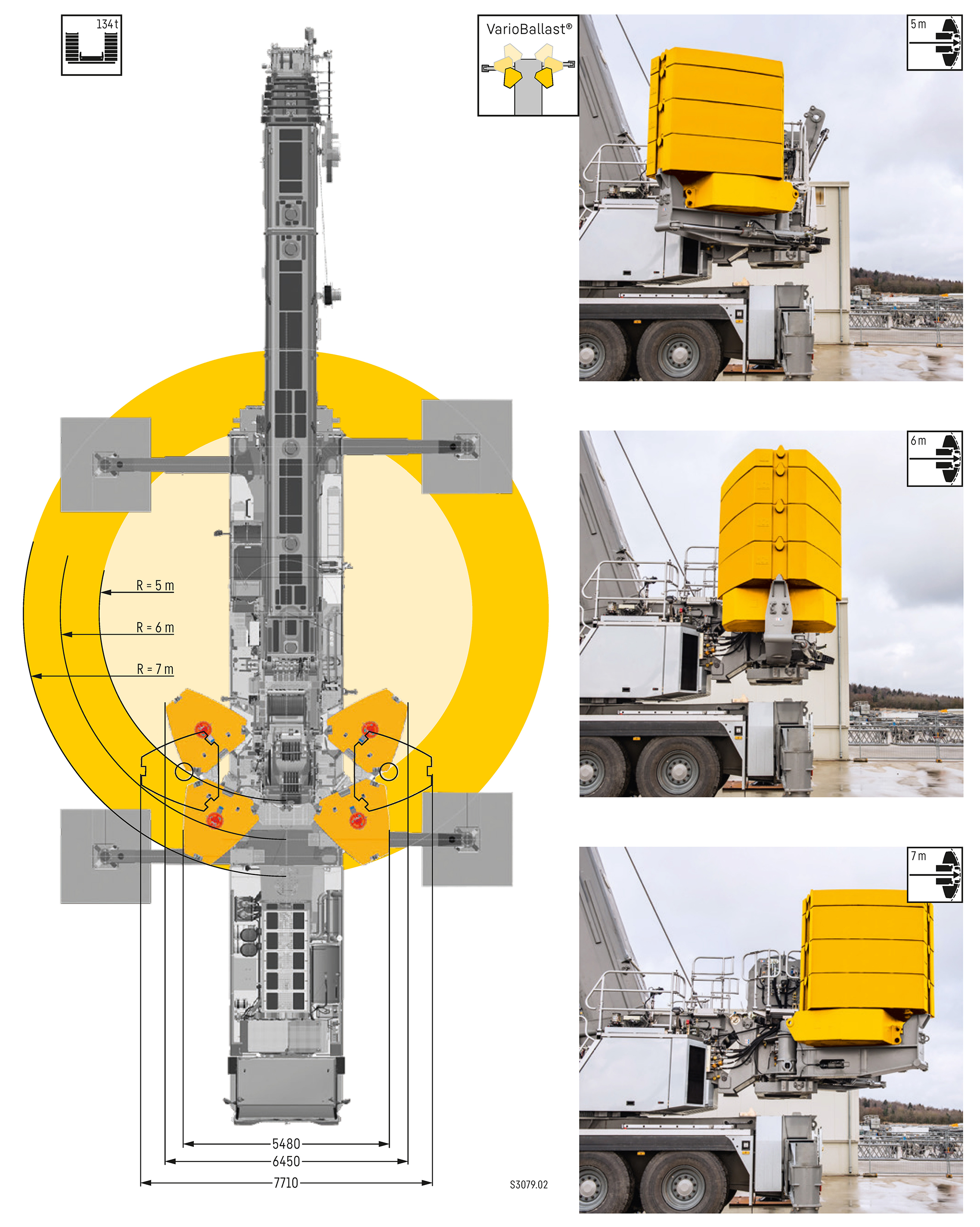

The LTM 1450-8.1 features a very long yet powerful 7-piece 85 metre (279 ft) telescopic boom. If greater height is required, a folding jib can be installed quickly, whilst a fixed jib or powerful luffing jib can also be attached. These are controlled using time-tested telematics technology. The 8-axle crane has been designed for worldwide cost-effective mobility and fast, easy setup on site. Our large fast-erecting crane is capable of travelling on public roads with a 12-tonne (26,450 lb) axle load carrying its complete telescopic boom, all its outriggers and the complete hoist winch. This enables it to be prepared for use very quickly once it reaches the site. With its time-testing technology such as the infinitely variable hydraulically adjustable VarioBallast®, VarioBase®, the single-engine concept or ECOmode and ECOdrive, makes this crane the state of the art in crane technology.

Max. load capacity - 450 t

450 t

Telescopic boom - 85 m

85 m

Max. hoist height - 132 m

132 m

Max. radius - 103 m

103 m

Number of axles - 8

8

What's inside

Powerful:

Take one engine out to increase lifting capacity:

Everything on board:

Ready for anything:

Green:

Photo gallery

Technical data

| Max. load capacity | 450 t |

| at radius | 3.00 m |

| Telescopic boom from | 16.10 m |

| Telescopic boom up to | 85.00 m |

| Lattice jib from | 7.00 m |

| Lattice jib up to | 84.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 8-Zylinder-Diesel |

| Drive engine/power | 505 kW |

| Number of axles | 8 |

| Drive/Steering standard | 16 x 8 x 16 |

| Driving speed | 85.00 km/h |

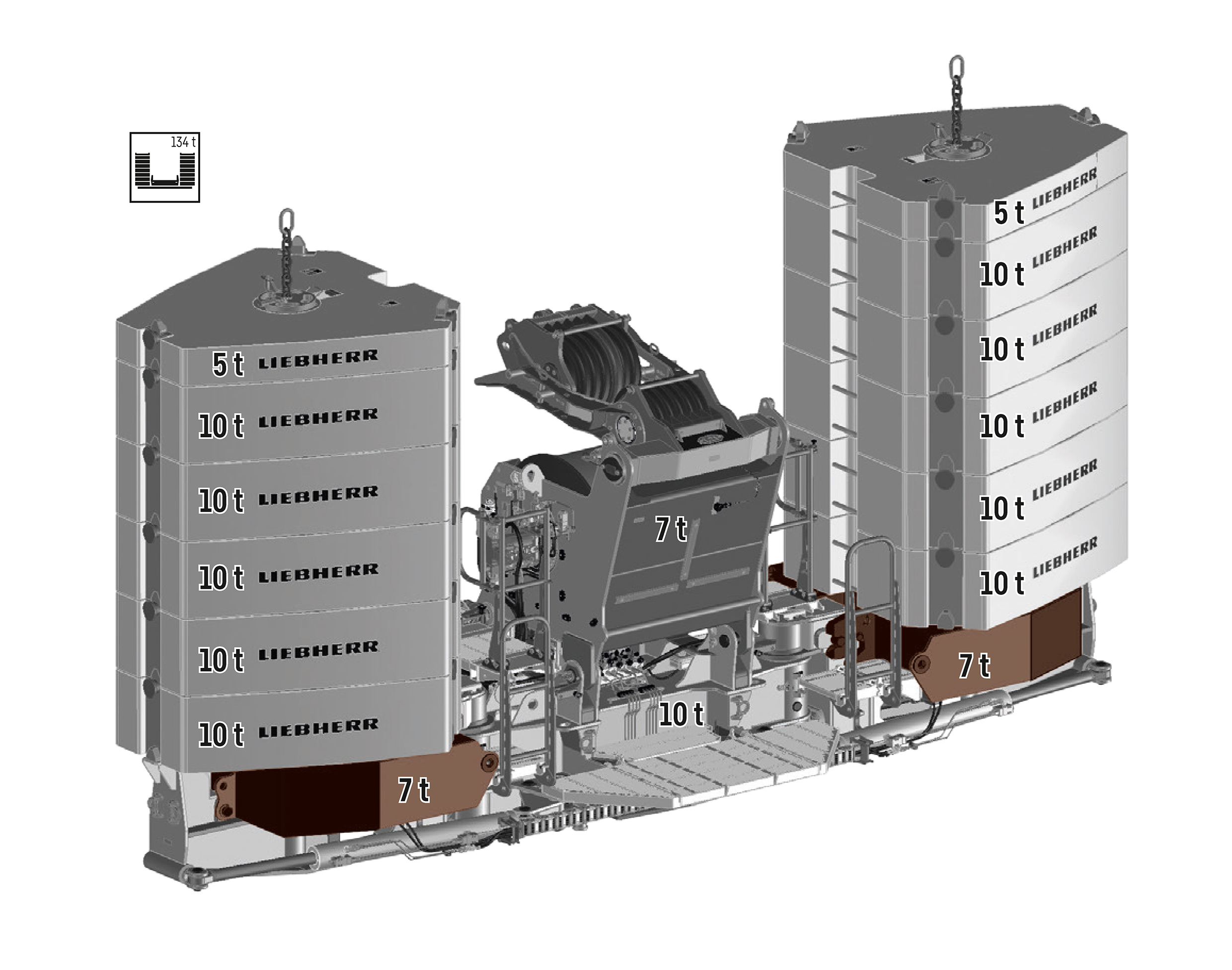

| Total ballast | 134.00 t |

Downloads

Boom/jib combinations

Boom/jib combinations

Driving conditions

On-road driving

Jobsite driving

Ballast systems

Counterweight

VarioBallast: Counterweight radius

Technology

ECOmode

ECOdrive

Single-engine concept

VarioBase®

VarioBallast® (hydraulic)

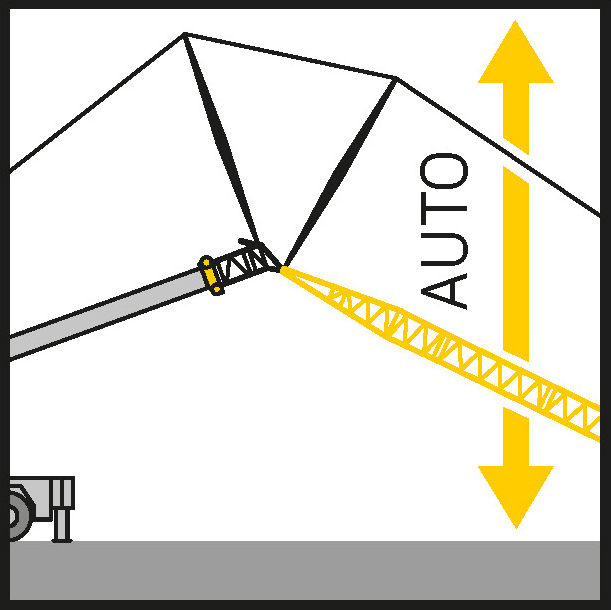

Automatic erection of the luffing jib

WindSpeed load charts