Components

Components

Decentralised energy systems

With the increasing population, the worldwide demand for energy is growing rapidly. At the same time, however, the demand for renewable and environmentally friendly technologies is also growing. A promising approach is to produce energy close to where it will actually be used. This means not only that transport losses can be reduced, but also infrastructure costs can be saved.

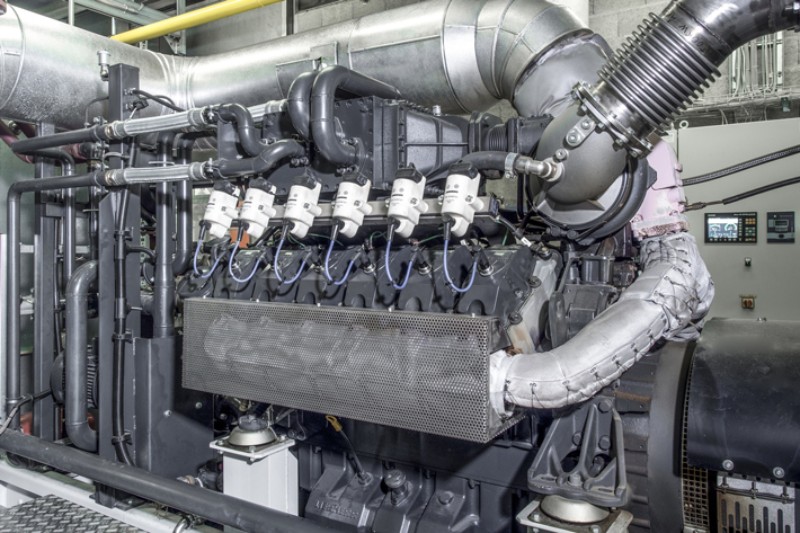

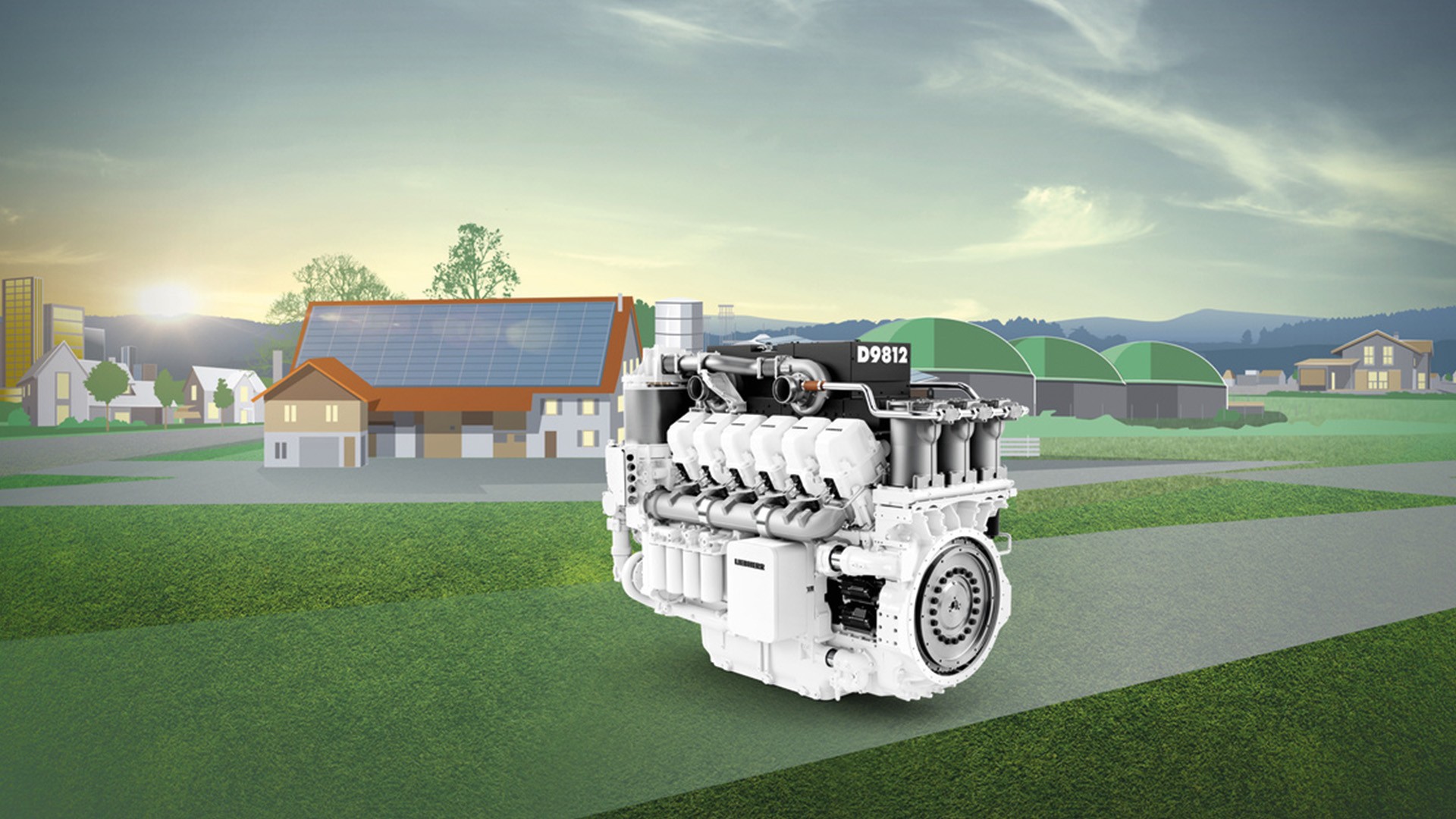

Liebherr gas engines contribute to environmentally friendly and location-dependent energy production in combined heat and power units or gensets. Engine operation is possible with a wide variety of gases. As a result, waste products, for example from biogas plants or sewage treatment plants, can be reused wisely.

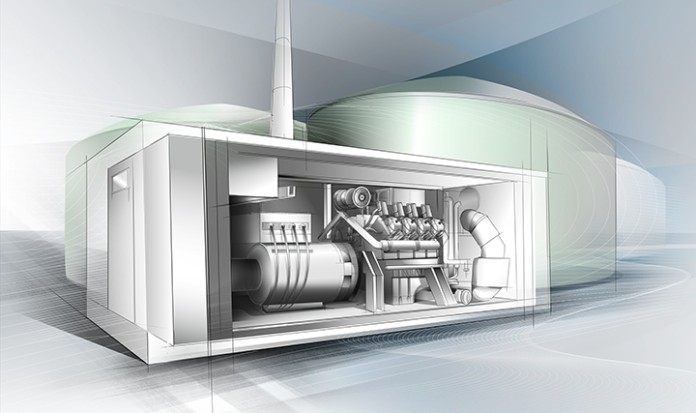

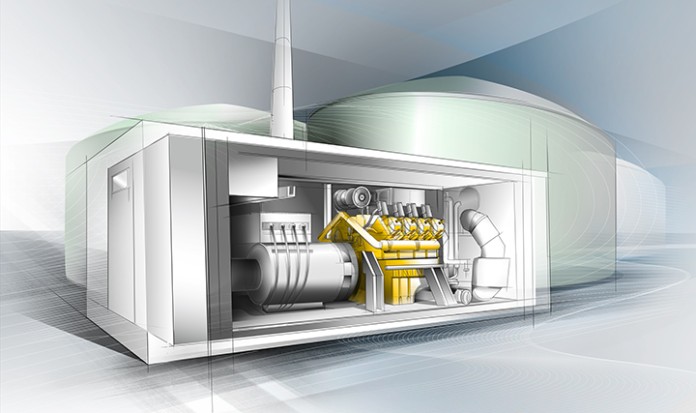

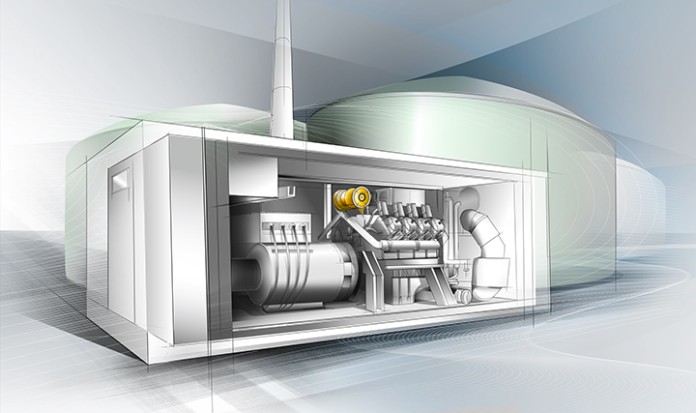

Liebherr components for decentralised energy systems

Liebherr gas engines are specially designed for decentralised continuous operation power supplies. The interactive graphics illustrates an example of a biogas plant, which makes our gas engines a perfect partner for your application.

Basic engine

Find out more

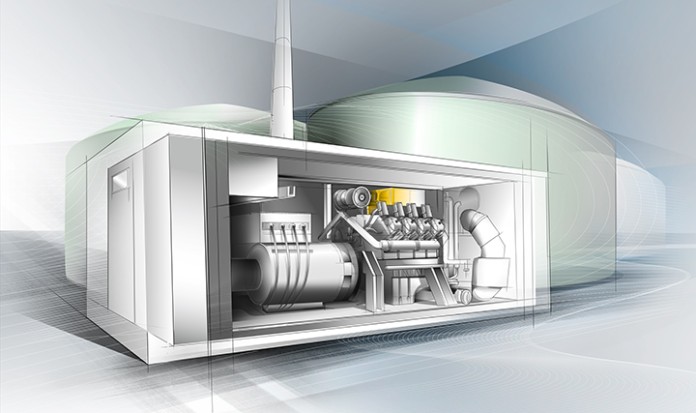

Gas mixer and turbocharger

Find out more

Two-stage stainless steel intercooler

Find out more

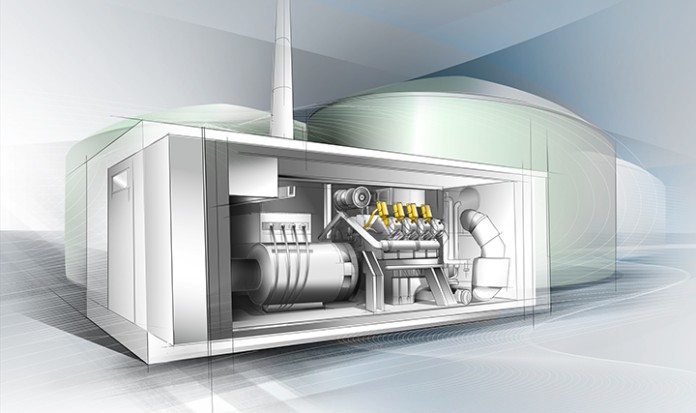

Ignition system

Find out more

Application examples

Liebherr gas engines are used in combined heat and power units as well as gensets. These are suitable for decentralised energy production in a wide range of end-use applications:

- Residential applications (multi-family houses, residential buildings, etc.)

- Industrial applications (hotels, restaurants, large-scale industries, IT centers, etc.)

- Applications in the public domain (railway stations, swimming pools, hospitals, nursing homes, etc.)

- Biogas plants

- Waste water treatment plants

- Agricultural businesses

- Pumping stations

Gas engines

Liebherr has many years of experience in the construction of gas engines. The first 6-cylinder gas engine was produced in Bulle in 1996. Today, the product portfolio includes different versions with 4 to 20 cylinders. The current generation of engines has consistently been matched to the requirements of stationary electricity and heat generation in combined heat and power units as well as gensets.

- Efficient: With a mechanical efficiency rating of over 43%, Liebherr gas engines offer the best efficiency values of their performance category.

- Reliable: Our gas engines are designed for continuous operation. Thanks to their high reliability and low downtimes, an availability of considerably more than 8,000 operating hours per year can be achieved.

- Service-oriented: Clearly visible and easily accessible parts make service work on the engines very easy. In addition, all components are selected and optimised with the aim of achieving the longest possible maintenance intervals. The result is a very attractive total cost of ownership (TCO) for Liebherr gas engines.

Versatile application possibilities

Full equipment gas engines

Liebherr gas engines are distinguished by a high degree of efficiency and availability. Therefore, the engines are supplied fully equipped.

Contact

Please contact us – we will answer your questions and put together an individual offer for you. If you need a component as a spare part for your Liebherr machine, please contact your local service partner.