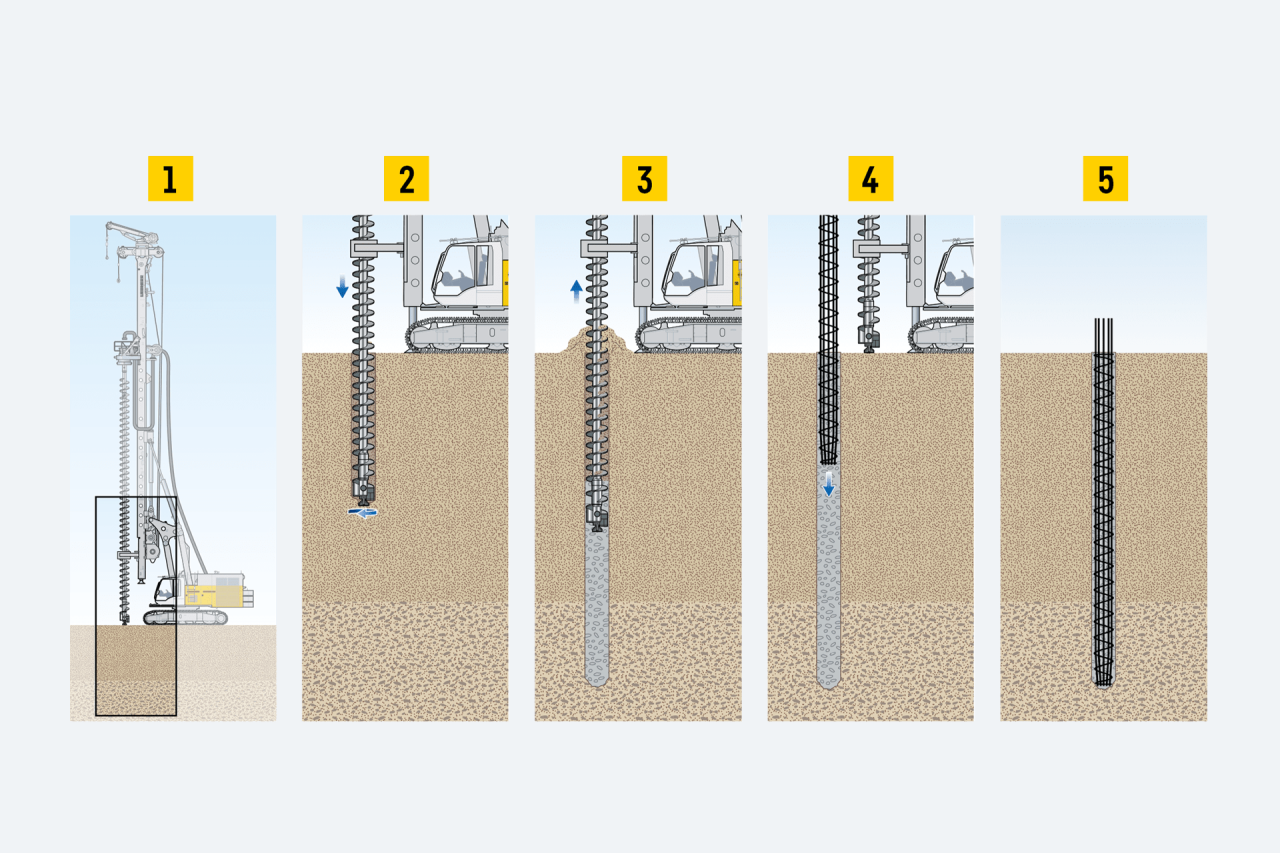

CFA drilling (cast-in-place piles)

Continuous flight auger drilling belongs to the dry rotary drilling methods. It is suitable for predrilling as well as for the installation of cast-in-place piles. The soil (under certain conditions also rock) is loosened and conveyed continuously using a continuous flight auger. The borehole wall is supported by the auger flights filled with drill cuttings.

Video: Continuous flight auger drilling

The video shows an LRB 125 installing cast-in-place piles using the continuous flight auger drilling method.

01/05

01/04

Machines

Results 1-6 of 15

1

2

3