Components

Components

Our Reman Program

A contribution to resource conservation and CO2 savings

Reduce the CO2 footprint through remanufacturing

Raw material resources such as metal, natural gas and oil are limited. Climate-relevant emissions are released during their extraction and further processing. Transport by air, land and sea further adds to their overall negative impact.

So resource conservation and climate protection are closely linked. This is where our Reman Program makes an important contribution by reusing pre-used components.

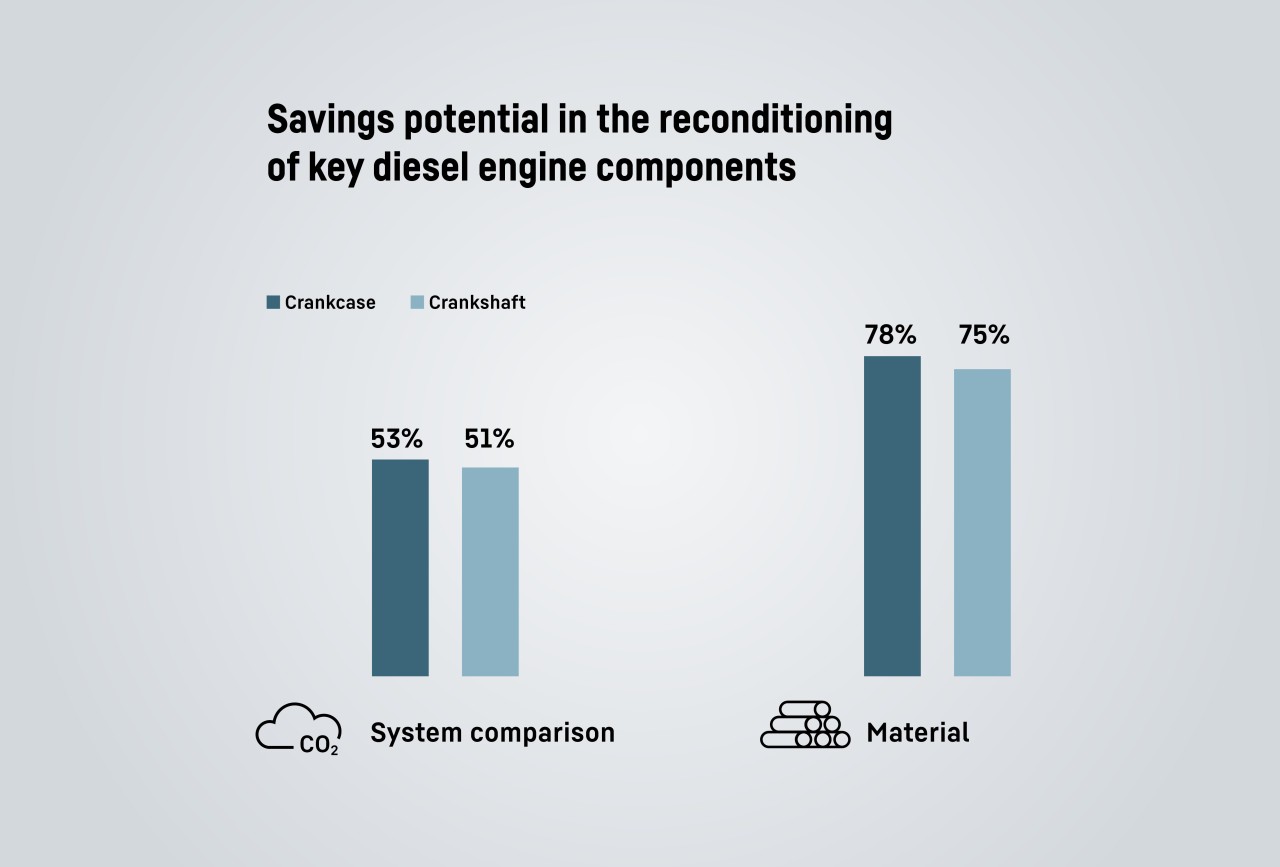

Savings potential

Together with an expert external consultant, the savings potential through remanufacturing, or specifically the reuse of components, was analysed in more detail. The largest parts of a diesel engine were used as a reference: crankcase and crankshaft. Here is an overview of the calculated savings potential through this analysis:

Remanufacturing

- The CO2 footprint can be reduced by about 60% through the remanufacturing of the analysed components.

- Since not all old parts can be reused, the actual saving is still just over 50%.

- The main reason for the saving is the elimination of the energy-intensive melting down of steel and cast iron if these parts were considered "scrap". In addition, there need for primary production of metals is reduced.

- Depending on the respective supply chains, the transport requirements for remanufacturing can be higher than for new part production. However, this additional CO2 emission is of minor importance compared to the savings already mentioned.