_w1920.jpg)

_w1920.jpg)

Bearing condition monitoring: Smart, digital and precise

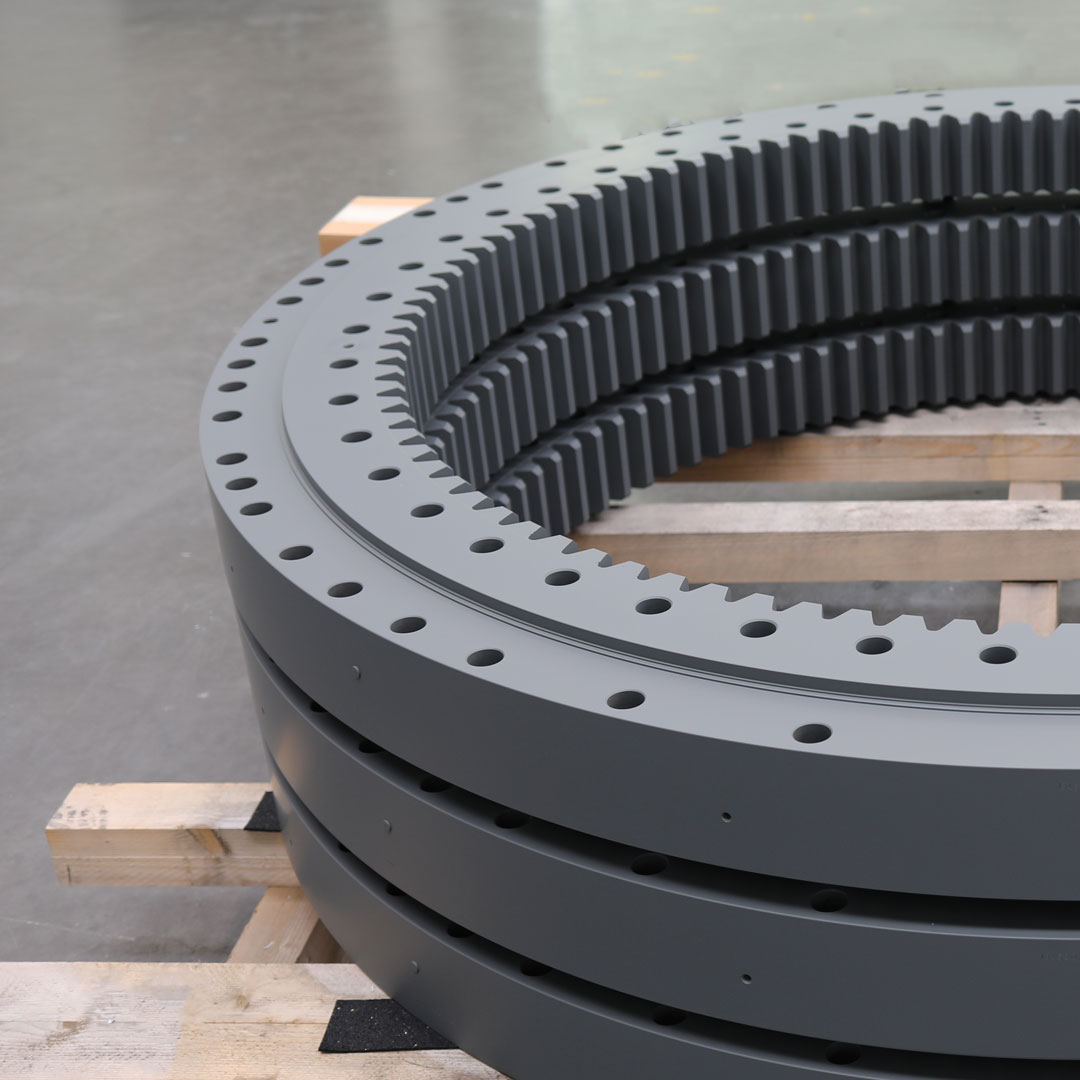

The fast and precise measurements with the digital Liebherr smart slewing bearing and sensors enable you to maintain your applications and operations with maximum efficiency. This ensures an optimal bearing condition monitoring in numerous applications.

Beside of bearing clearance measurement Liebherr offers solution for bearing monitoring temperature and water content for various applications and areas. Find out more about the numerous applications for bearing condition monitoring!

Reduced downtime: simple and fast

Integrated sensors, precise monitoring, and user-friendly evaluation systems provide within our bearing monitoring for reduced downtimes and increased productivity and lifetime of your components and applications.

Safety: integrated and remote

Our bearing condition monitoring guarantees the safety of staff during measurements through its integrated and digital operation. Service planning, maintenance, spare parts exchanges, and inventory can be executed with maximum efficiency.

.jpg)

Cost efficiency: save 75% or more

The Integrated and digital measurement and evaluation reduces your costs by 75% or more per measurement. You want to know how much you would save by implementing our bearing clearance monitoring?

Application-specific solutions

Next level bearing monitoring and maintenance

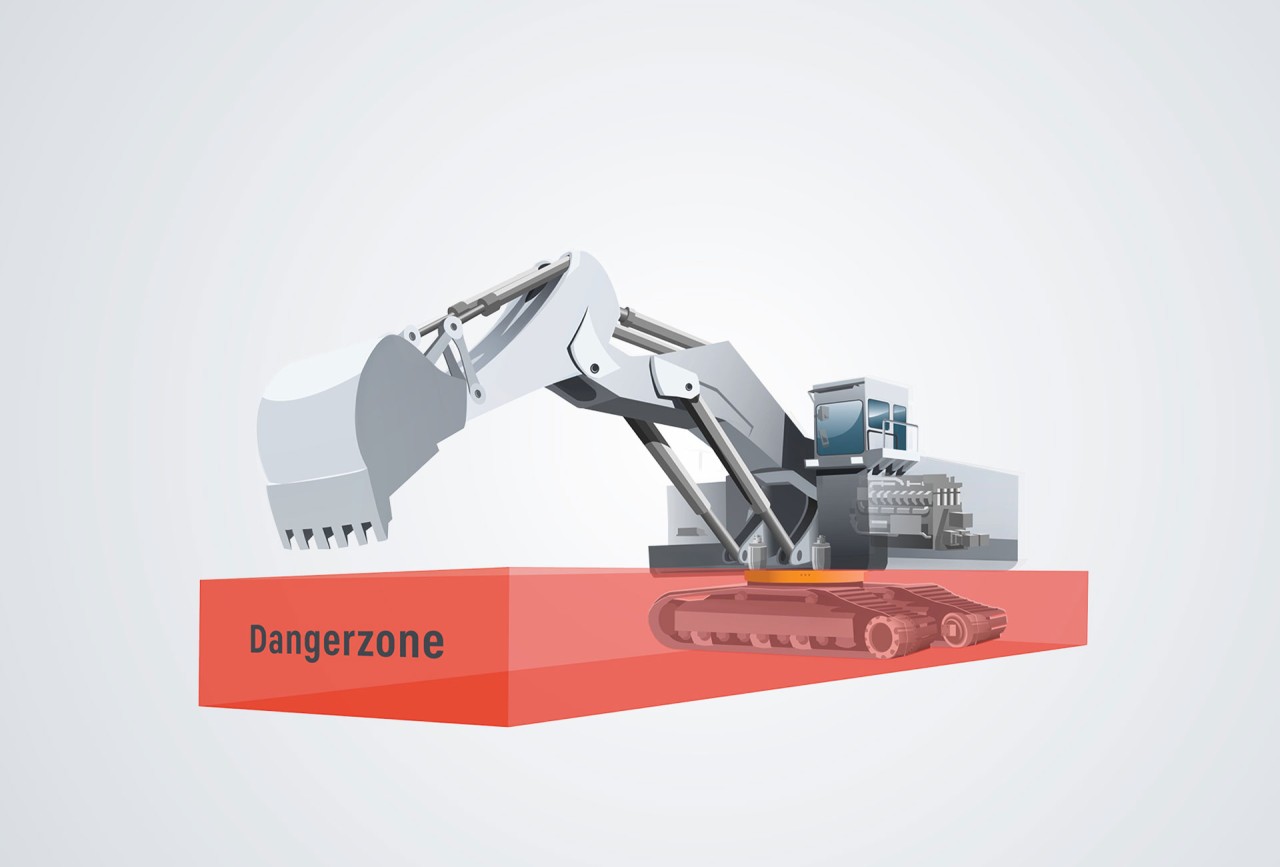

Bearing clearance monitoring (BCM) for mining excavators:For the operation and maintenance of excavators, BCM offers the technologically leading digital bearing monitoring solution. It provides for maximum safety and efficiency saving 75% or more of the costs per measurement.

Bearing temperature monitoring (BTM): Through integrated sensors, the temperature of bearings can be measured at any time. The digital monitoring solution provides for operational safety of the application.

Improve the lifetime of your components with bearing monitoring

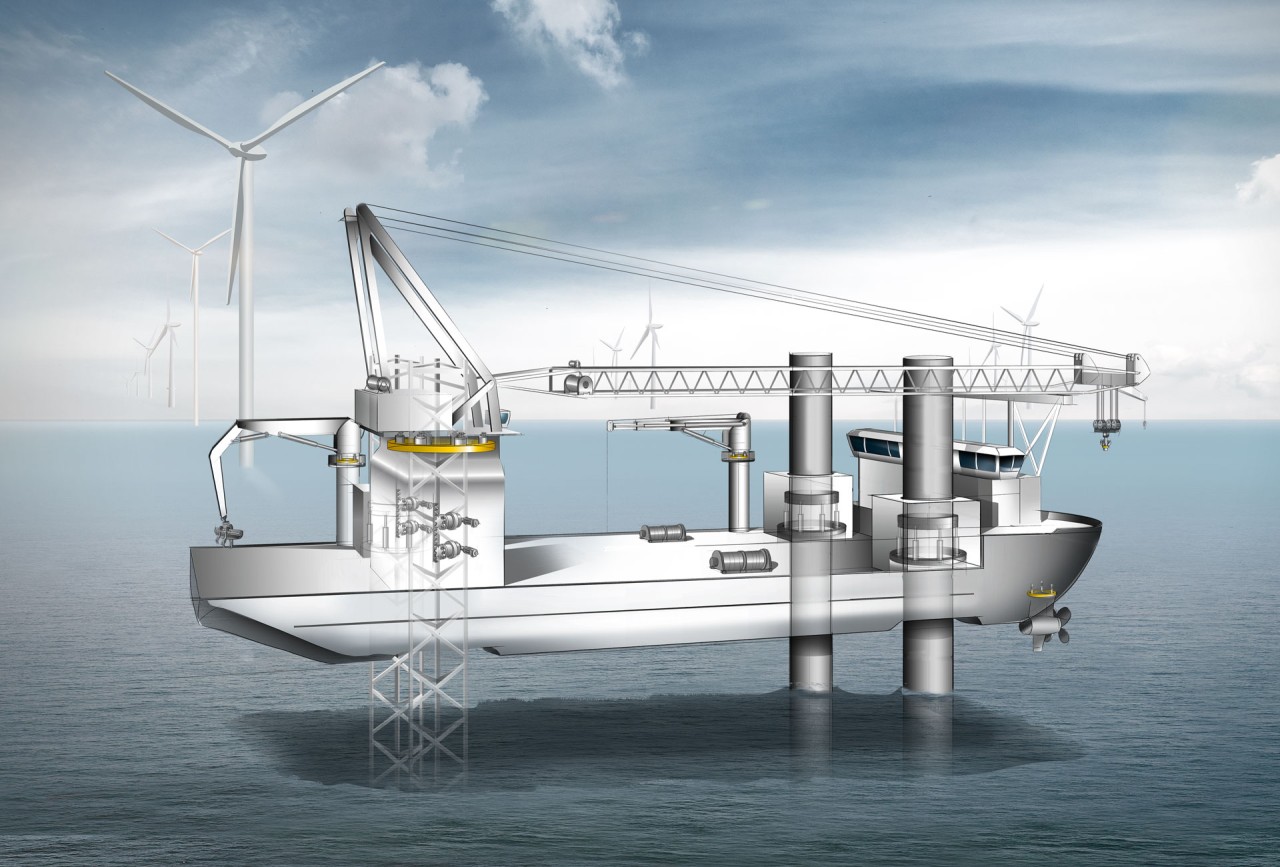

Bearing clearance monitoring (BCM) for platform and heavy lift cranes: For the operation and maintenance of maritime cranes, BCM offers the technologically leading digital monitoring solution. Because the measurement can be carried out remotely, it minimizes the risk of failure and provides for maximum safety for the staff.

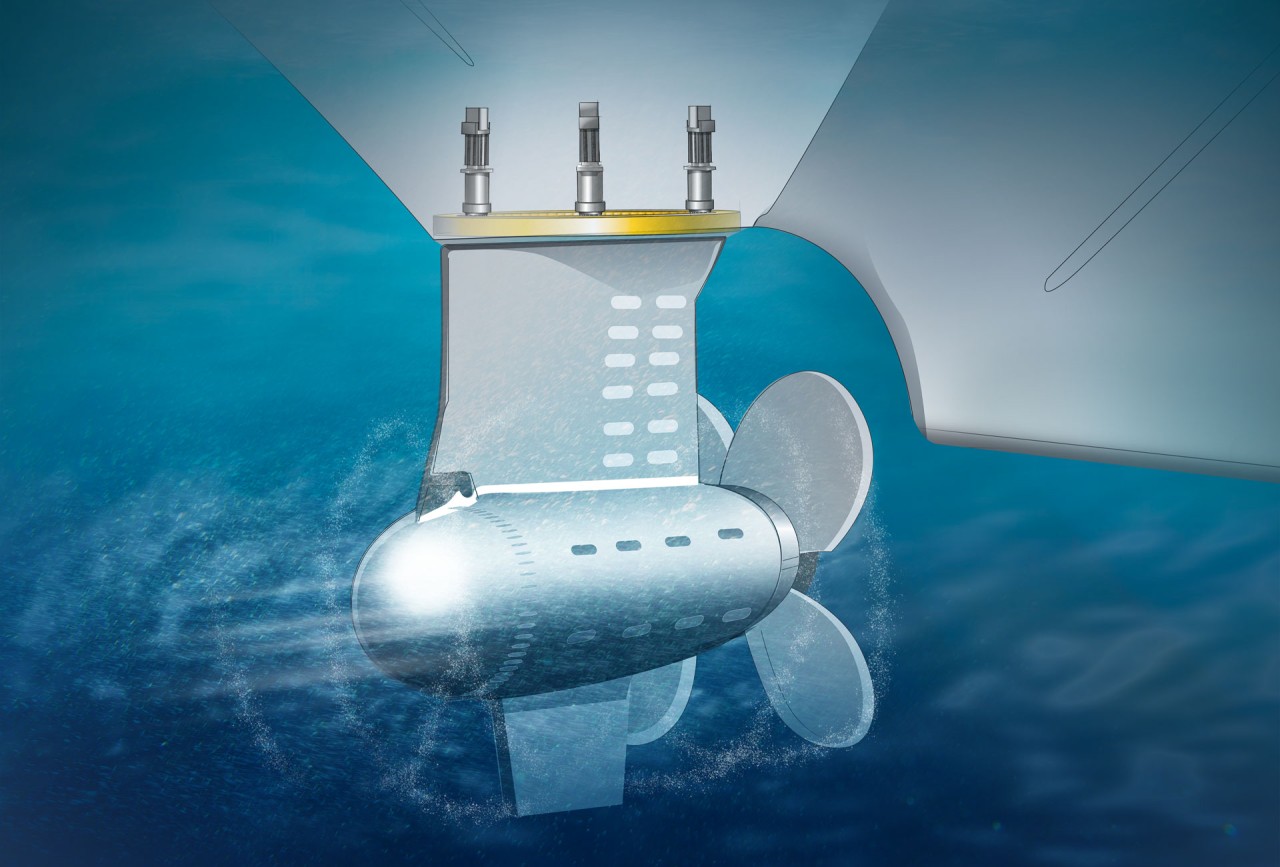

Water content monitoring for thrusters and other applications: Integrated sensors determine water content in the sealing spaces of bearings in applications that operate near or under water.

Bearing monitoring on the high seas

Bearing lubrication monitoring (BLM) for thruster:

Water content can be measured at any time via a sensor within the bearing monitoring. This can trigger the service seal, which ensures maximum safety.

The service seal, activated by compressed air, protects the raceway system against seawater ingress and prevents major damage to the bearing. The advantage of this special service seal tested at Liebherr is that the ship can still be steered and the ship can still sail to the nearest port or shipyard for repairs.

Operational safety and cost efficiency with bearing monitoring

Bearing clearance monitoring (BCM) for bucket wheel excavators: For the operation and maintenance of bucket wheel excavators, BCM is the technologically leading digital monitoring solution. The clearance measurement can be carried out remotely at any time. This is not only time-efficient but also ensures maximum safety for the staff.

Bearing temperature monitoring (BTM): The temperature of bearings can be measured at any time through integrated sensors. The digital monitoring solution provides for operational safety of the application.

Monitoring functions

Components Identification:Digitalized recognition of components and allocation of an end device.

Components Service: Condition monitoring (CM) involves querying the condition of the slewing bearing. This is classified in a trend analysis, which is used to create a forecast for the future. Based on CM, predictive maintenance can be introduced. With Predictive Maintenance information on the future condition of a component is predicted and recommendations for action are made based on this.

Component Update: Remote services also include flashing software that runs directly on a component.

Bearing clearance monitoring: This is how it works

Bearing condition monitoring areas

On time wear monitoring – smart, integrated, remote

Bearing clearance monitoring sensor technology provides for maximum safety and effciency of your operation.

Safety: No staff required directly at the vehicle.

Accurate and comparable: Integrated sensors.

Cost saving: >75% per measurement.

Independence: Measurement is possible at any time, without specialized personnel.

The standard so far is manual clearance measurement.

Manual measurement means:

- Staff in the danger zone: Manual mounting and reading of dial gauges in the area of main load zones.

- Long down times: ~ 3hrs/measurement.

- Dependency: Organization of qualified services.

- Inaccuracy: Manual mounting of the dial gauges and changing measurement positions may cause inaccuracy.

The Liebherr solution: Bearing clearance monitoring

Integrated sensors deliver precise data: More accurate data compared to conventional clearance measurement.

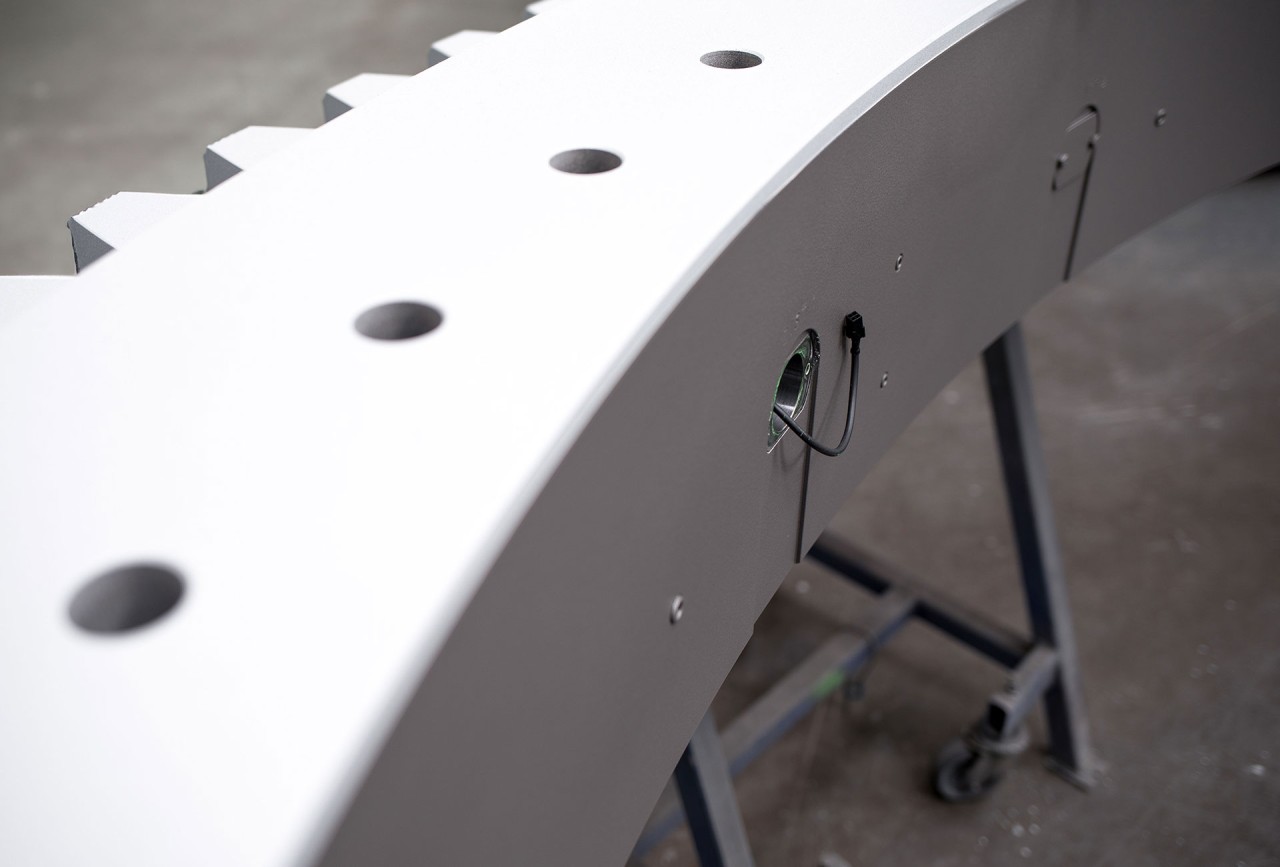

Sensor positions: Slewing Bearings will be deliverd with sensors integrated at opposite measuring points of the bearing fixed to the upper carriage.

Measurements can being taken at 360° position of each specific application.

Data download and evaluation: All product data can be downloaded from the application through a gateway installed on the application.

How our stand-alone solution works

1. Sensor connection box receives data from the sensors. It also supplies the entire system with power.

2. Data storage: All data is stored in the gateway.

3. Updates are possible via Bluetooth. Also thanks to the data connection via Bluetooth you can manage the wear status of your complete fleet via the same application on your selected device.

Monitoring data can be demanded and downloaded through the web-based app

The advantages of the software integrated BCM

- Fully compatible: Seamless integration into the control system of your machine

- Your system: You can use your own logic and interface to integrate the measurement data with our specifically developed and protected code into your system

- Component reduction: No additional gateway is required or necessary, leading to less system complexity due to the software integrated BCM

- Application range: our software integrated BCM offers versatile application possibilities and seamless integration into various designs

- Safety: without requiring technicians to perform manual checks in hard-to-reach areas

- Cost-saving: reduce downtime by up to 75%

Our BCM – your system: Software integrated BCM

The bearing clearance monitoring upgrade with the use of MIB (machine integrated block) allows a seamless integration into your control system.

All the measurement data taken from the integrated sensors of the slewing bearing go directly into your own control system. This allows an easy integration into the system landscape and therefore no separate devices or measuring equipment are needed.

How does it work?

1. The connection box receive data from the sensor. It supplies the system with power (24V DC)

2. We provide a specially developed and protected code to translate the measurement data

3. Your control system will then use the code to visualise the measurement data

4. You can use your own logic and interface to integrate the measurement data

Corrosion monitoring – smart, integrated, remote

Integrated digital water content measurement: Litronic sensors by Liebherr determine water content in the slewing bearing with high precision.

Cost and time saving: Data regarding the condition of bearings can be drawn at any time via digital mobile devices or control instruments without operational downtimes. Measurement and early warning system at any time.

Safety under or near water: The components of applications that operate under or near water can be protected with maximum efficiency and safety by the integrated Litronic sensors.

Litronic planar sensor

High precision, defined measurement windows: The measurement windows and sensitivity of our Litronic Planarsensors are adjustable. Limit values can be set using software according to the application’s demands.

Fully reproducible sensors: If applications are subsequently extended or added to the operation or if sensors are replaced, no recalibration is necessary. The sensors have built-in microprocessors.

Waterproof and dustproof: The sensor is suitable for harshest environments thanks to its IP68 protection class.

Minimize downtime – smart, integrated, remote

Integrated digital temperature measurement: Liebherr sensors determine the temperature within the slewing bearing to provide for the safety of the application during operation.

Reduce repair cost and efforts: Detect serious bearing failures and prevent consequential damages for other components of your application.

Data regarding the temperature of bearings can be drawn at any time via digital mobile devices or control instruments without operational downtimes.

Integrated sensors and gateway

For all countries: The integrated sensors and the gateway have worldwide approval.

Everything from a single source: The step-by-step development and subsequent production take place in-house at Liebherr.

Safe and robust: The sensor and the gateway meet all relevant safety standards and are ideally suited for robust environmental conditions.

Flexible to the max: BCM, BLM, BTM are working with all relevant types of bearing.

Sensor connection

Installation: The sensor connection box is being installed in the carriage of the application.

Data connection: It draws data from the sensors and sends them to the system gateway via the system’s network connection.

Power supply: The sensor connection box supplies the entire system with power.

Gateway

Data storage: The gateway stores all data derived from the sensors and makes it available directly to the application’s system or to the Liebherr APP via Bluetooth.

Web-App: The data can be downloaded via Bluetooth and evaluated within the Web-App on laptops or tablets.

Maintenance planning teams can access all data via the cellular network and define required service actions.

GPS: The application with components in need of service can be located via GPS.