Technology leader and development partner

As a technology leader and partner with decades of experience in the development of application-specific solutions, we understand the specific requirements of the industry and its applications. Take a look at our components for various applications in the maritime environment:

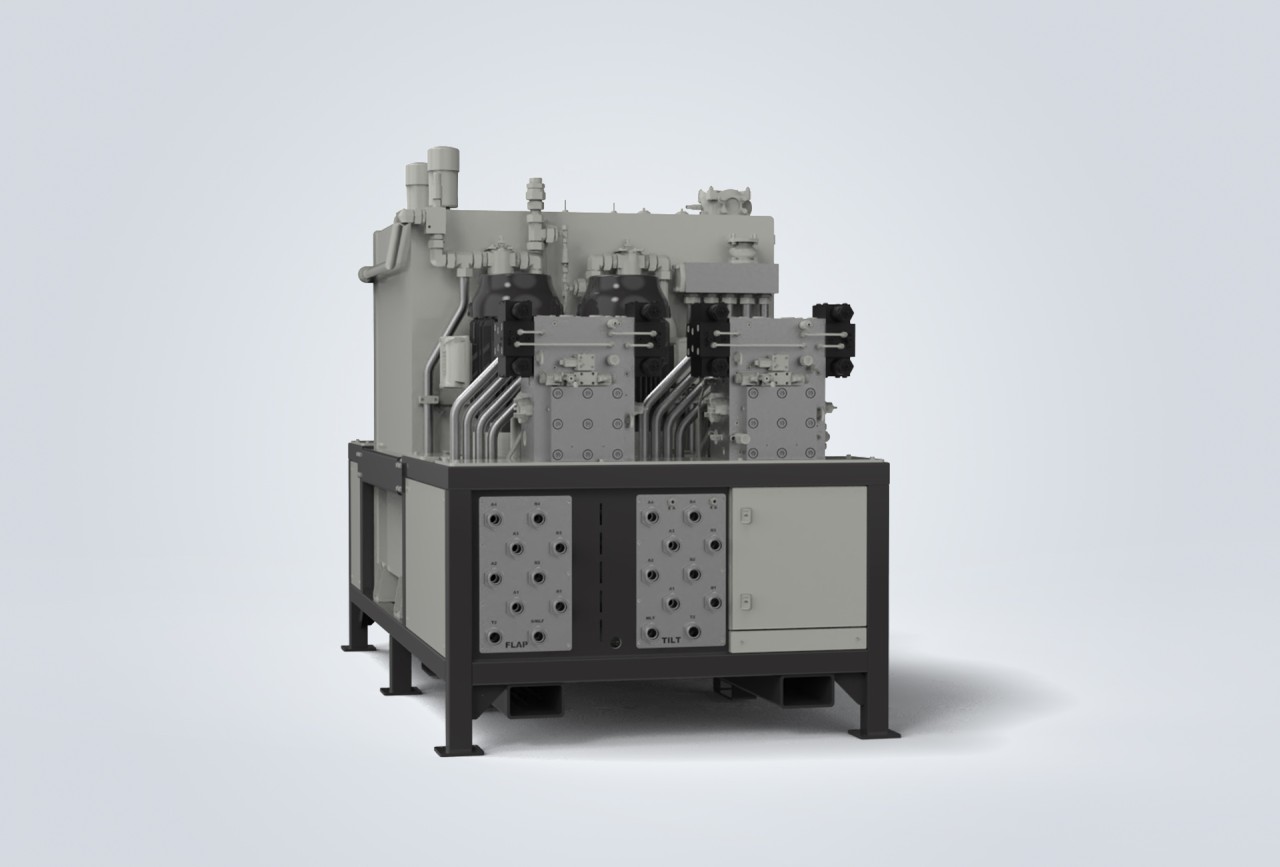

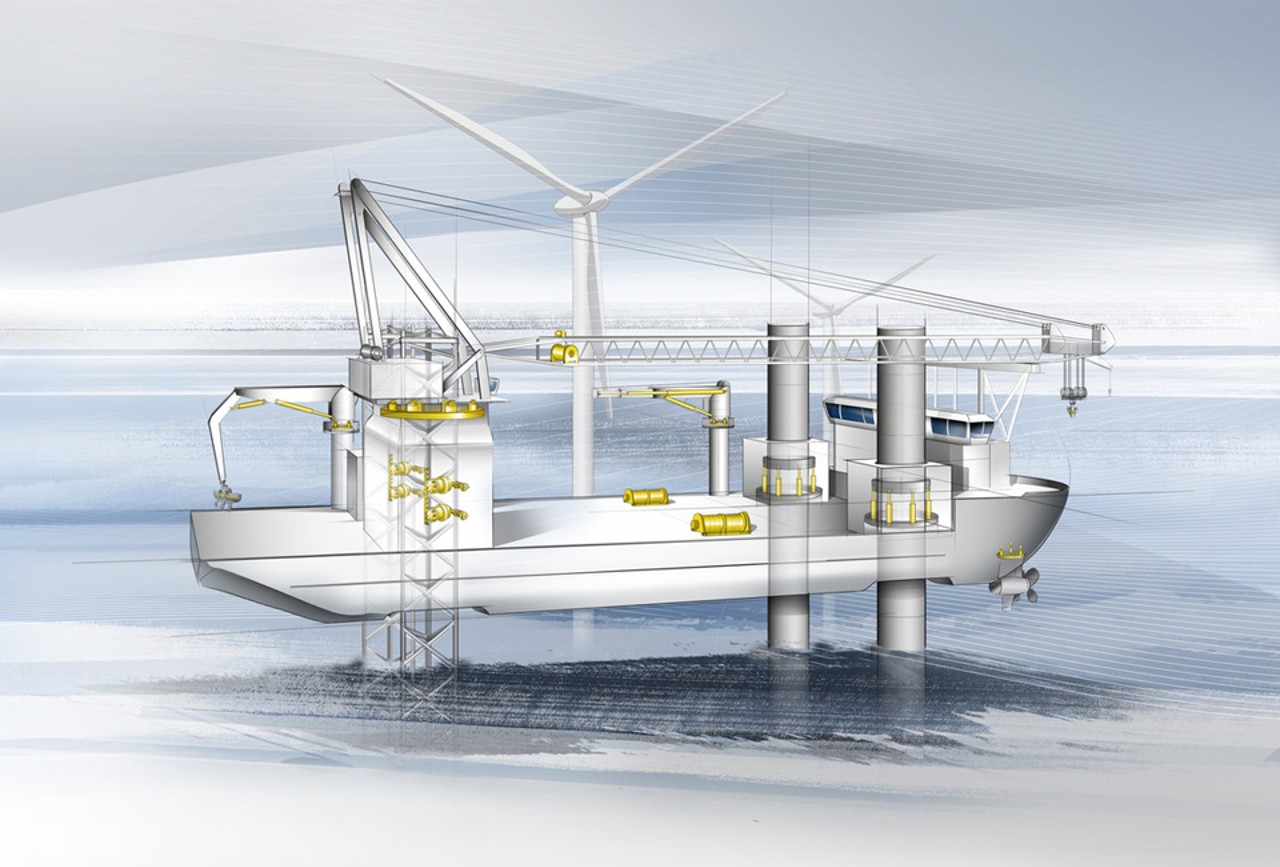

Drive solutions for ship and offshore cranes

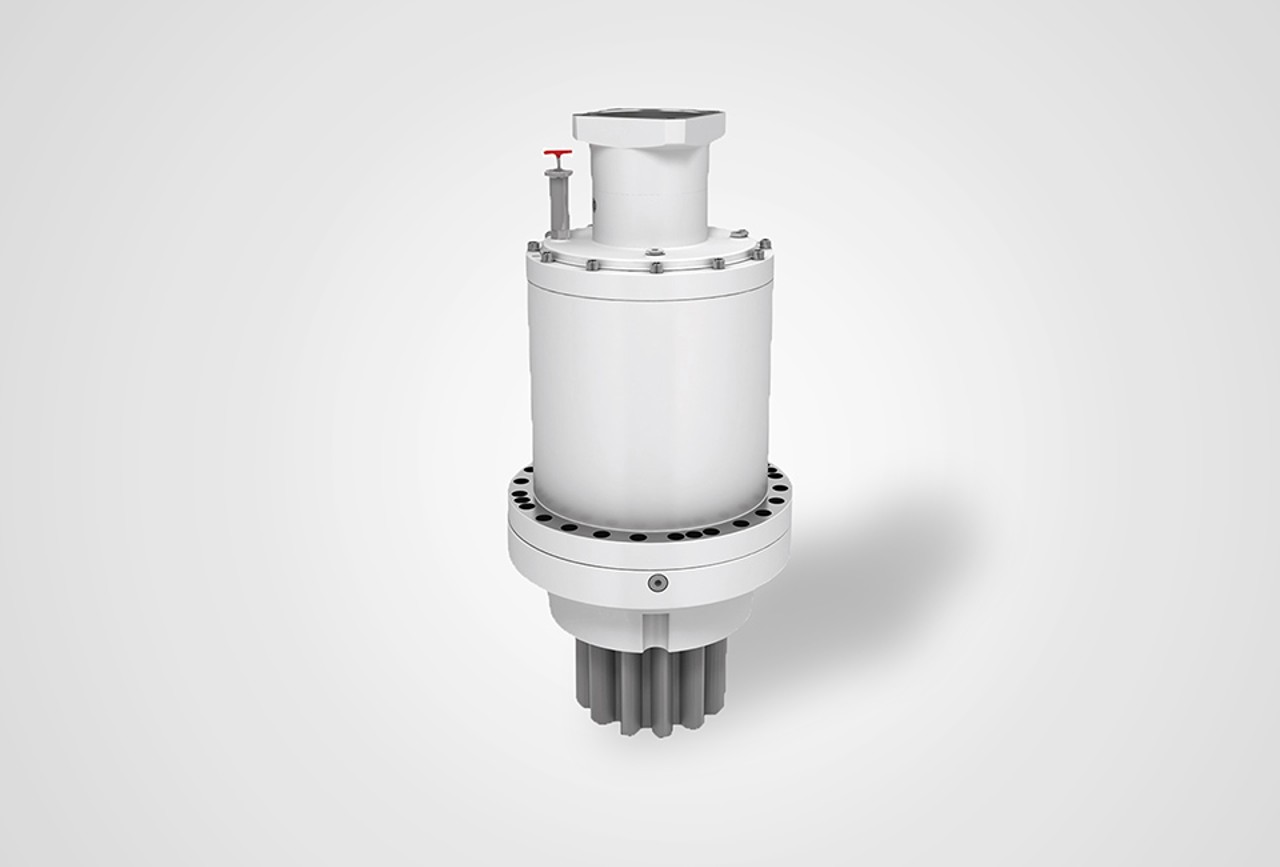

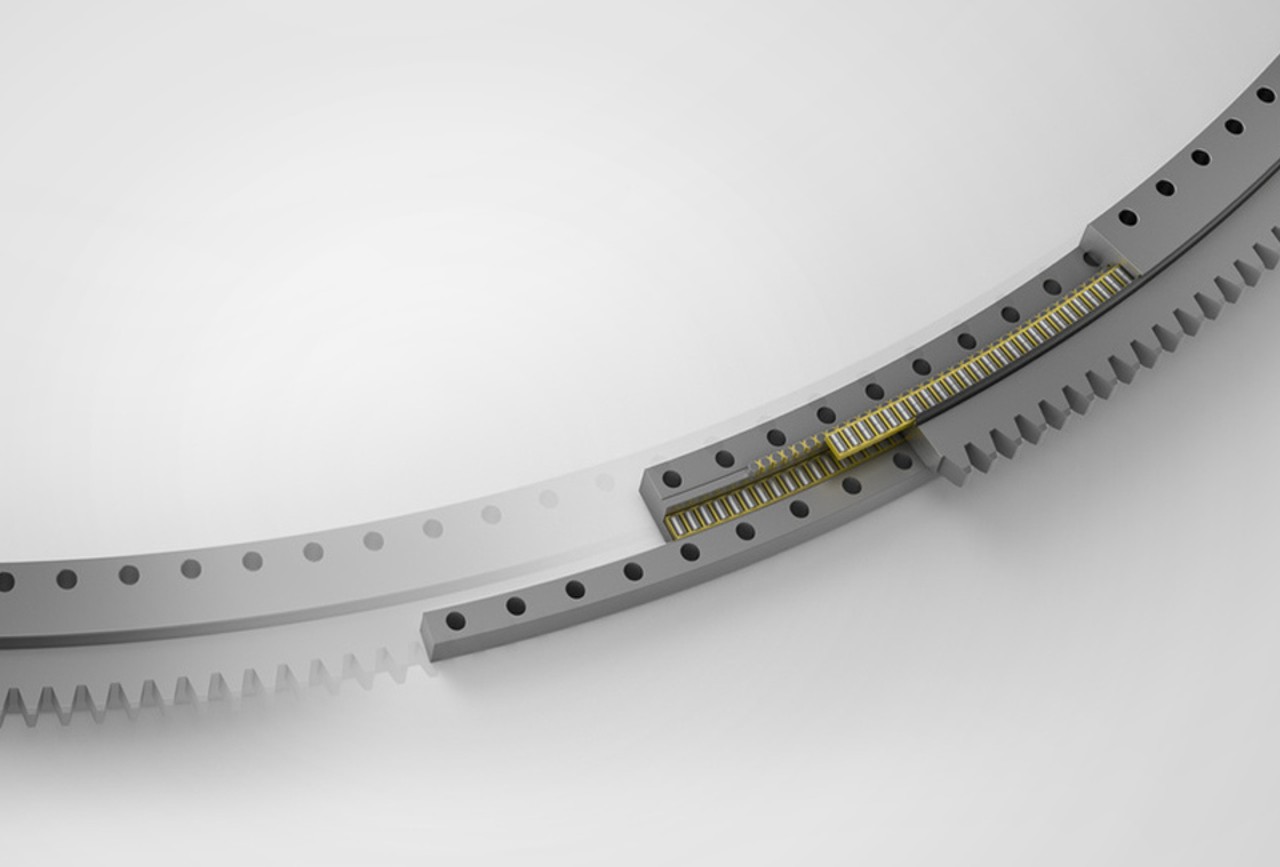

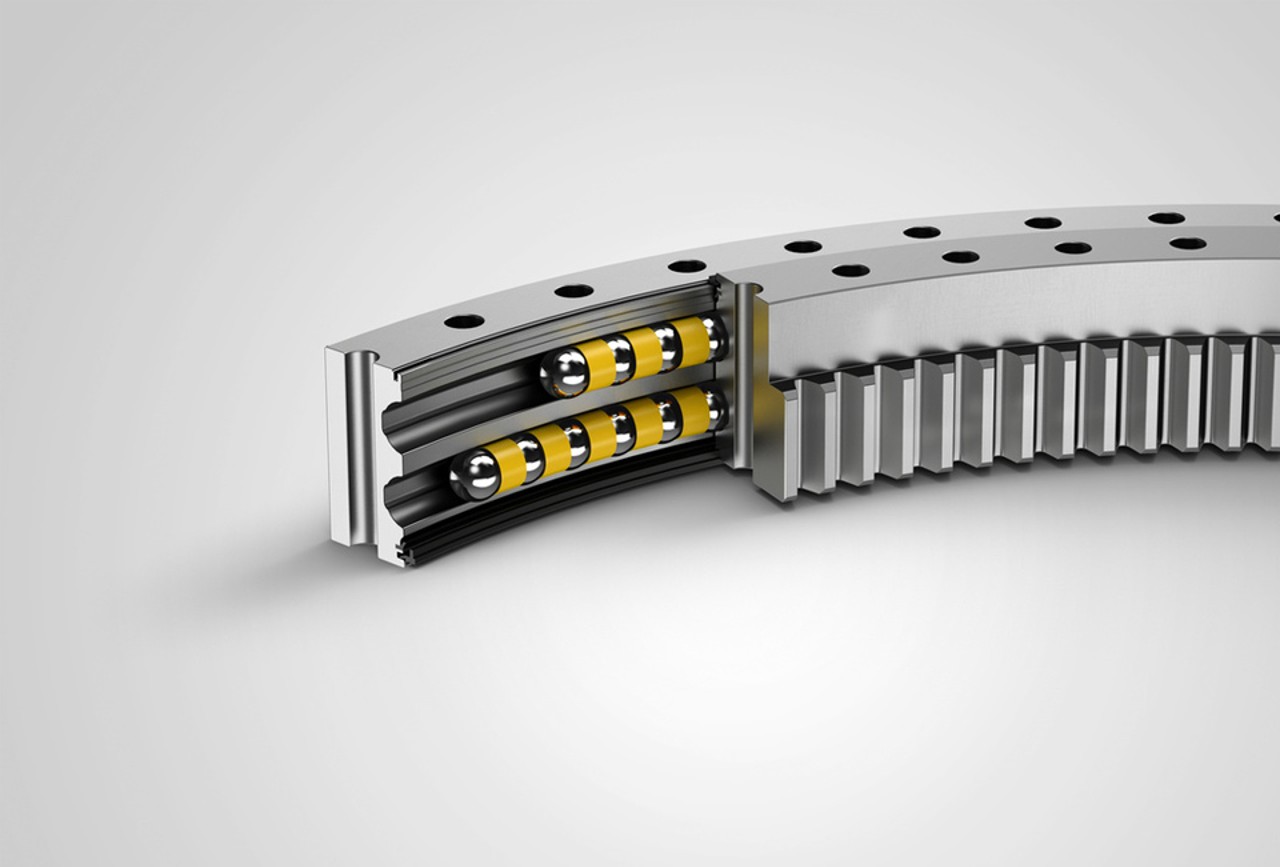

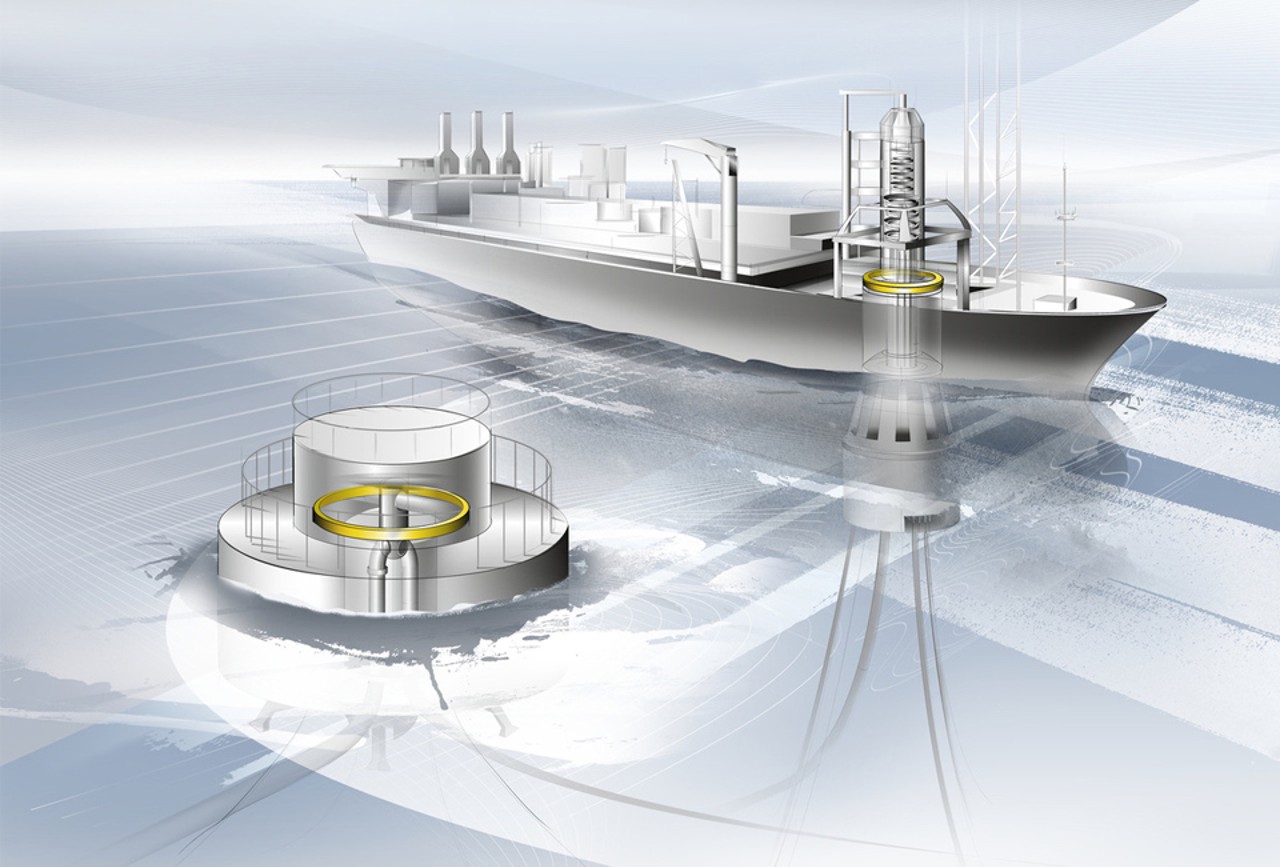

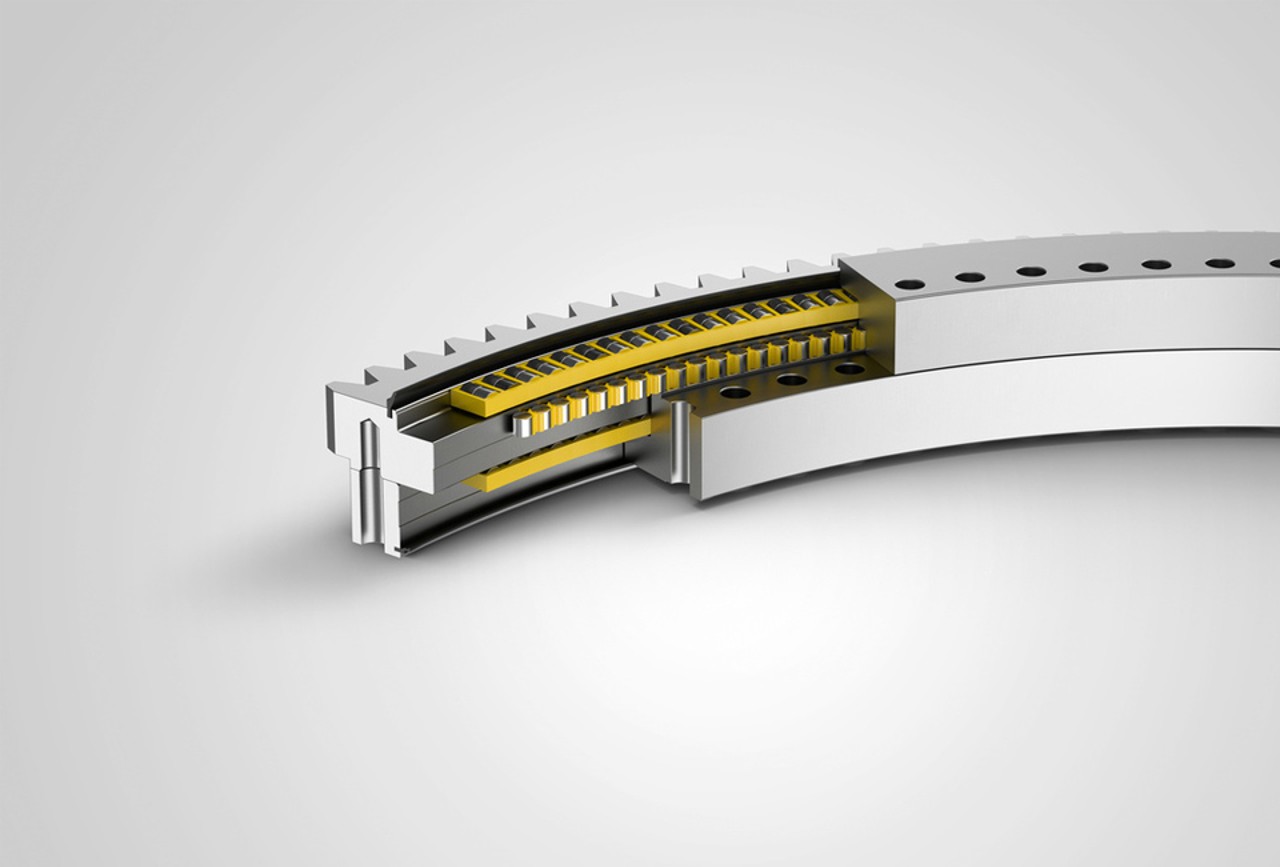

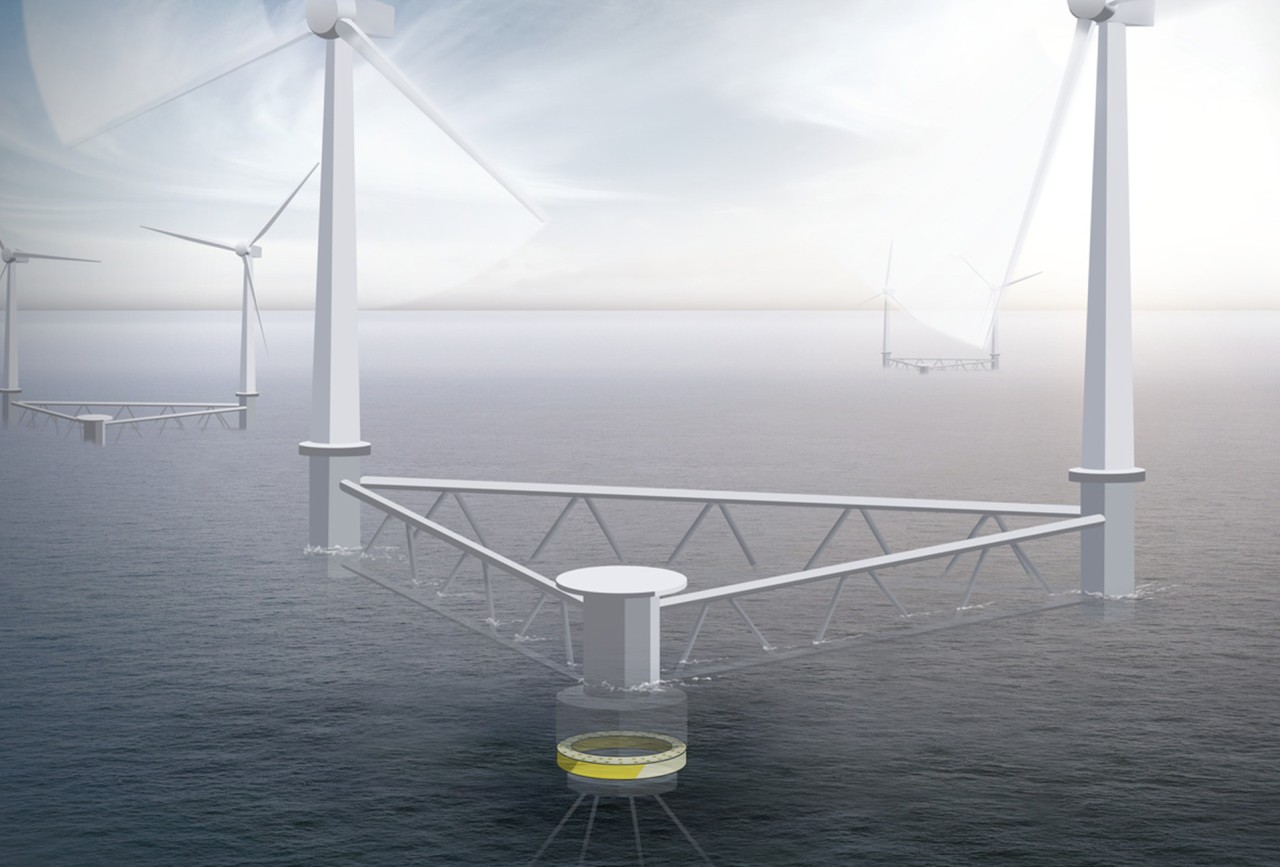

Components for turrets and buoys

Certified

Available

Application-specific solutions

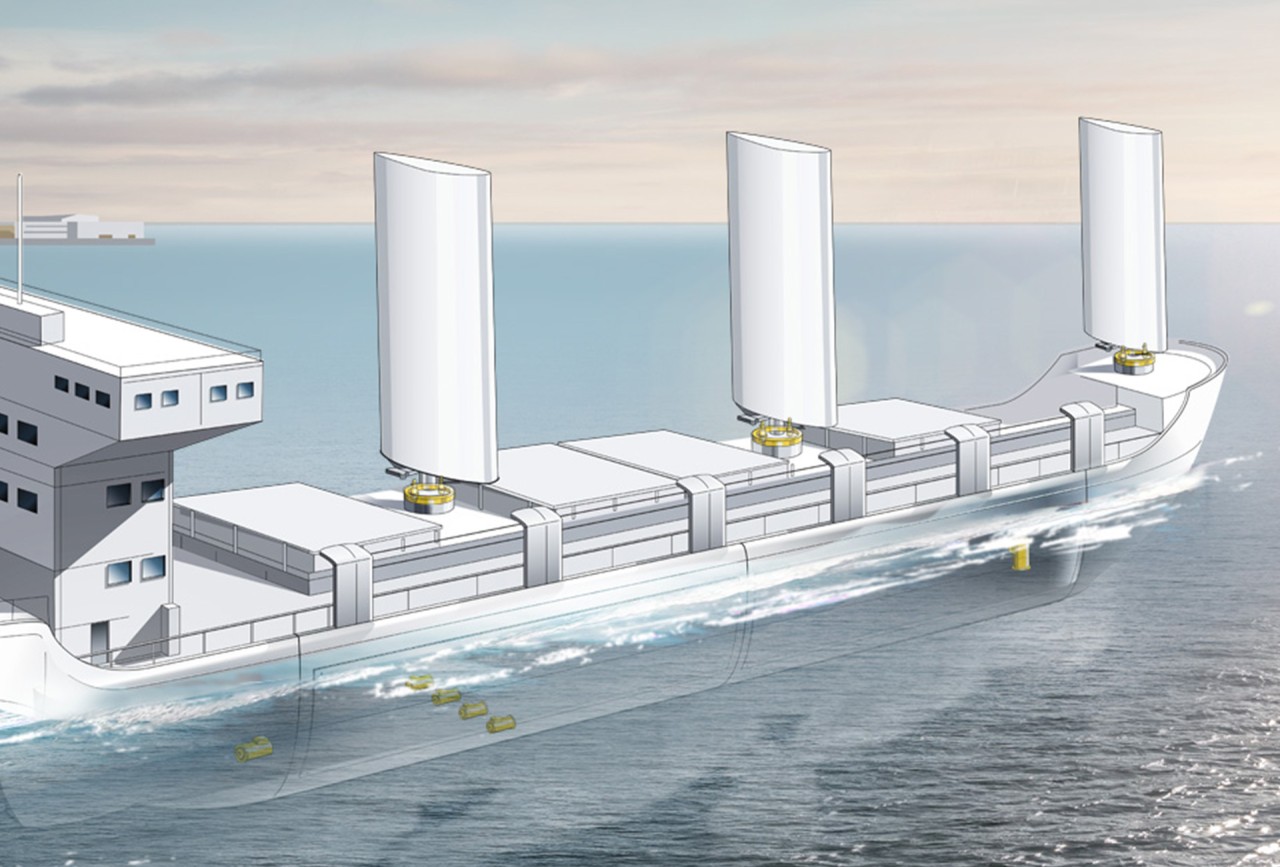

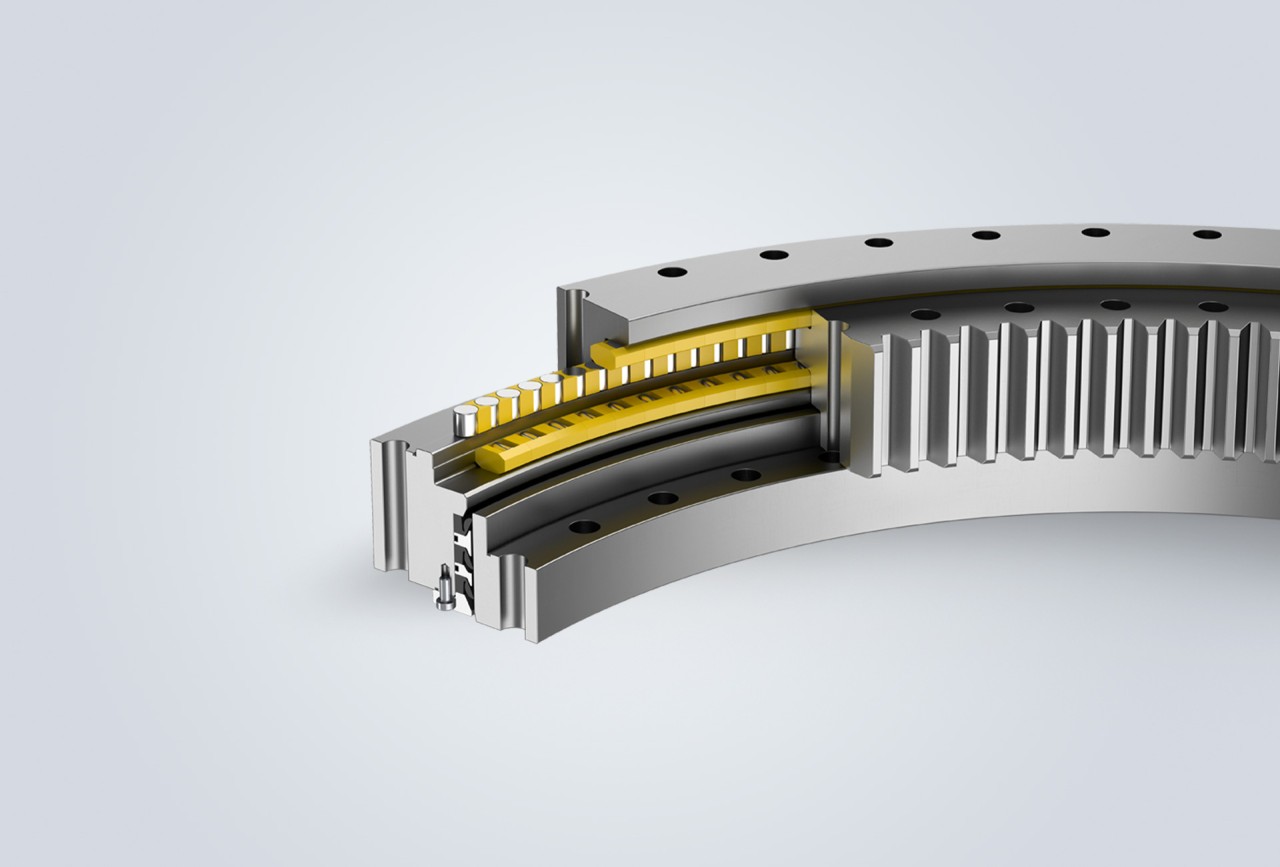

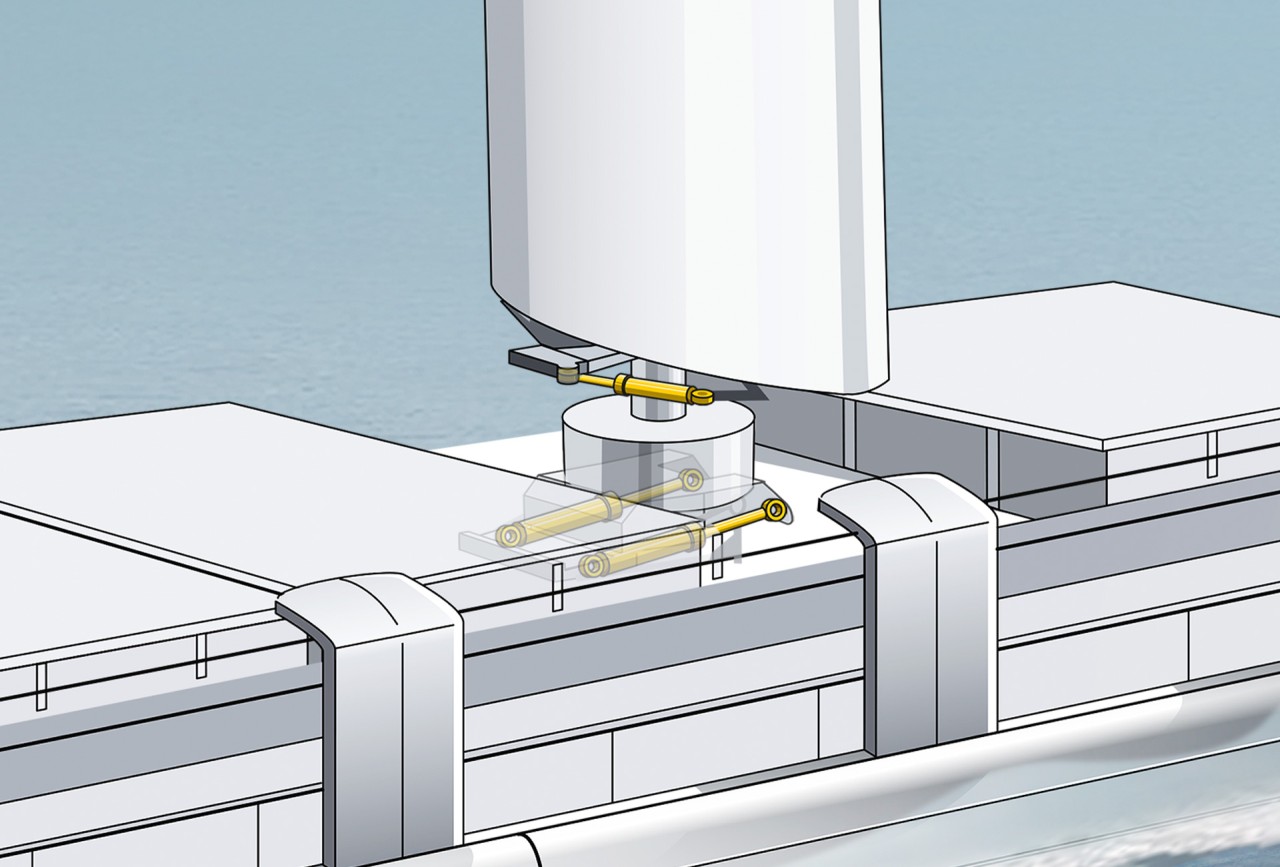

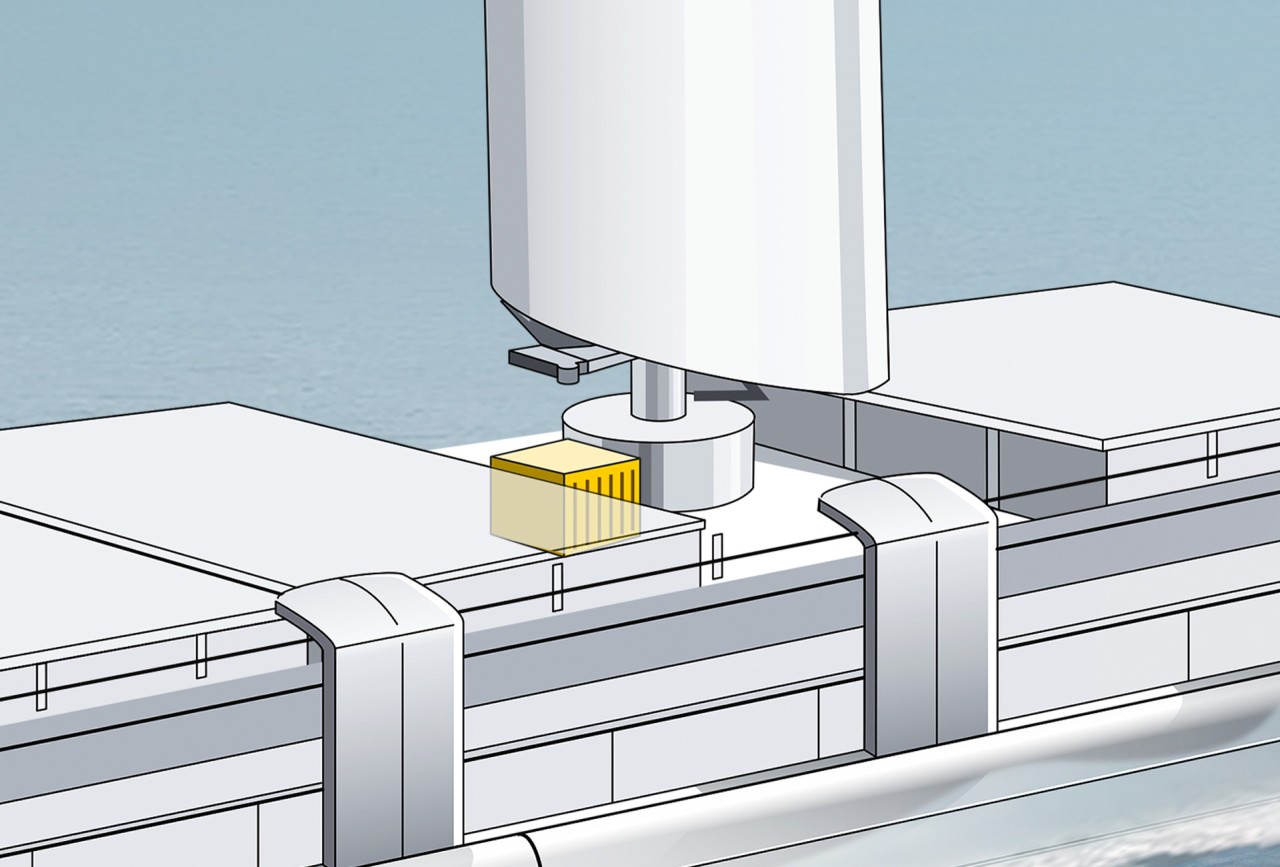

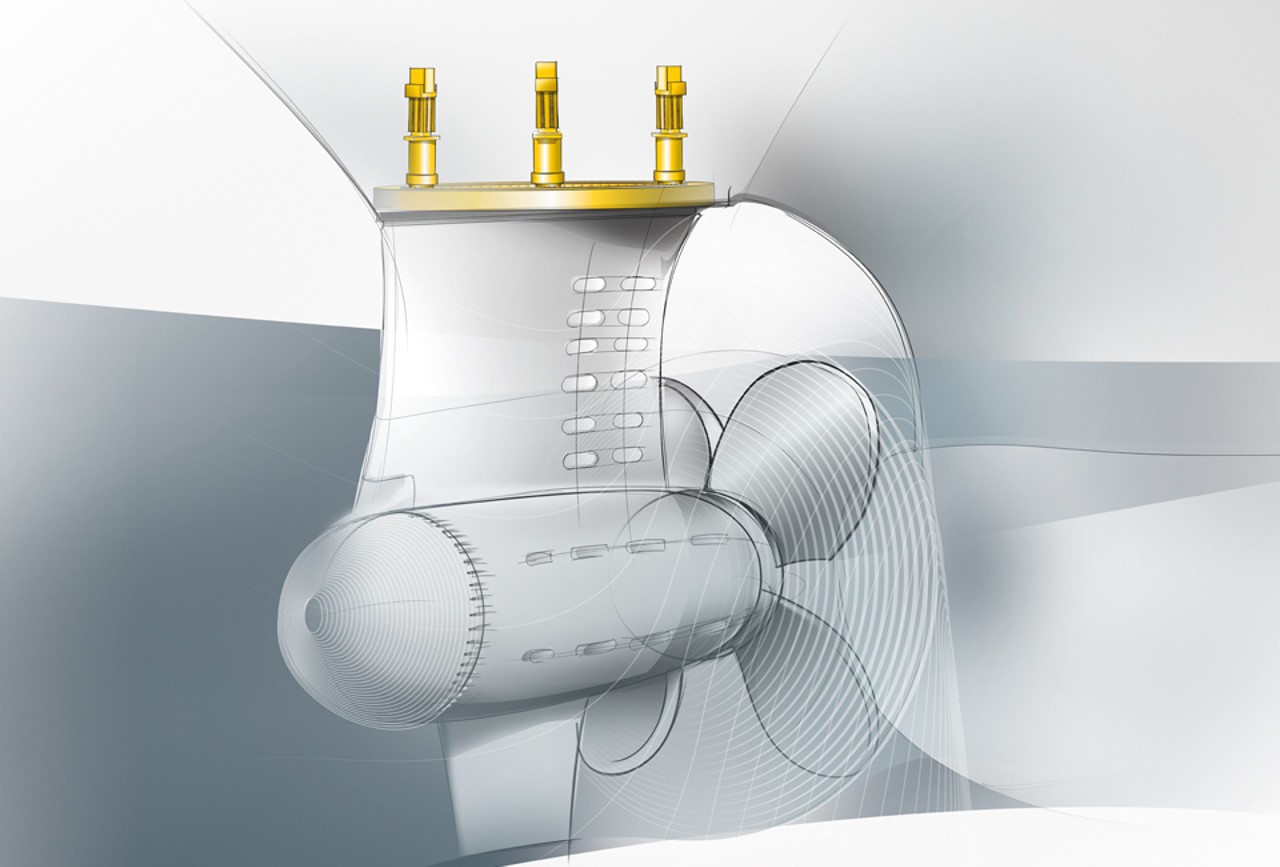

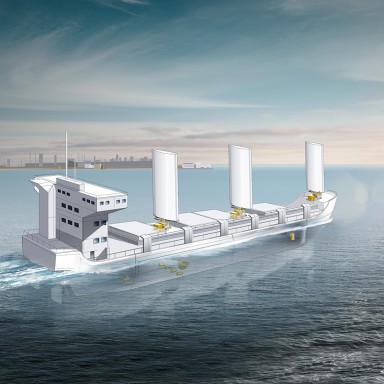

Wind-assisted propulsion

Liebherr offers a complete solution for wind-assisted propulsion, including slewing bearings, drives, and hydraulic cylinders.

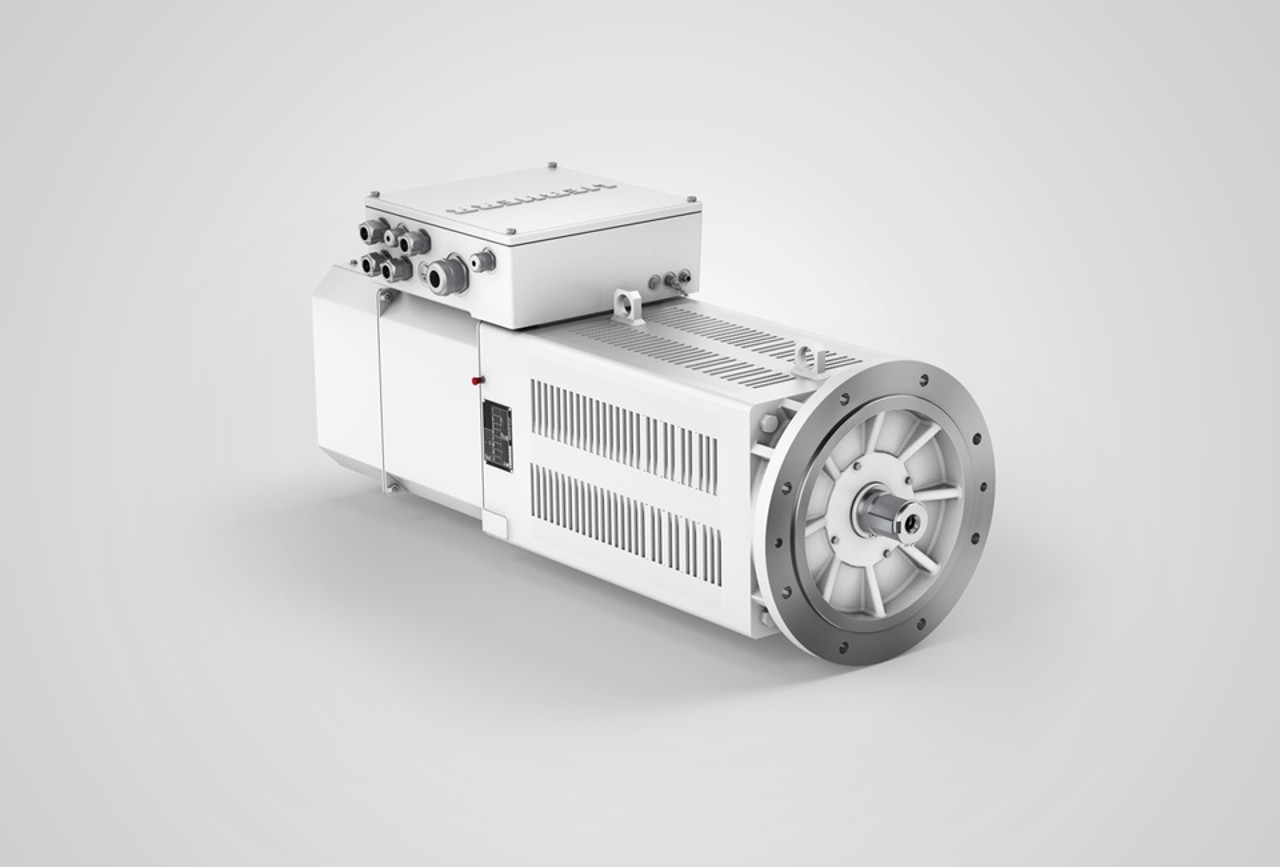

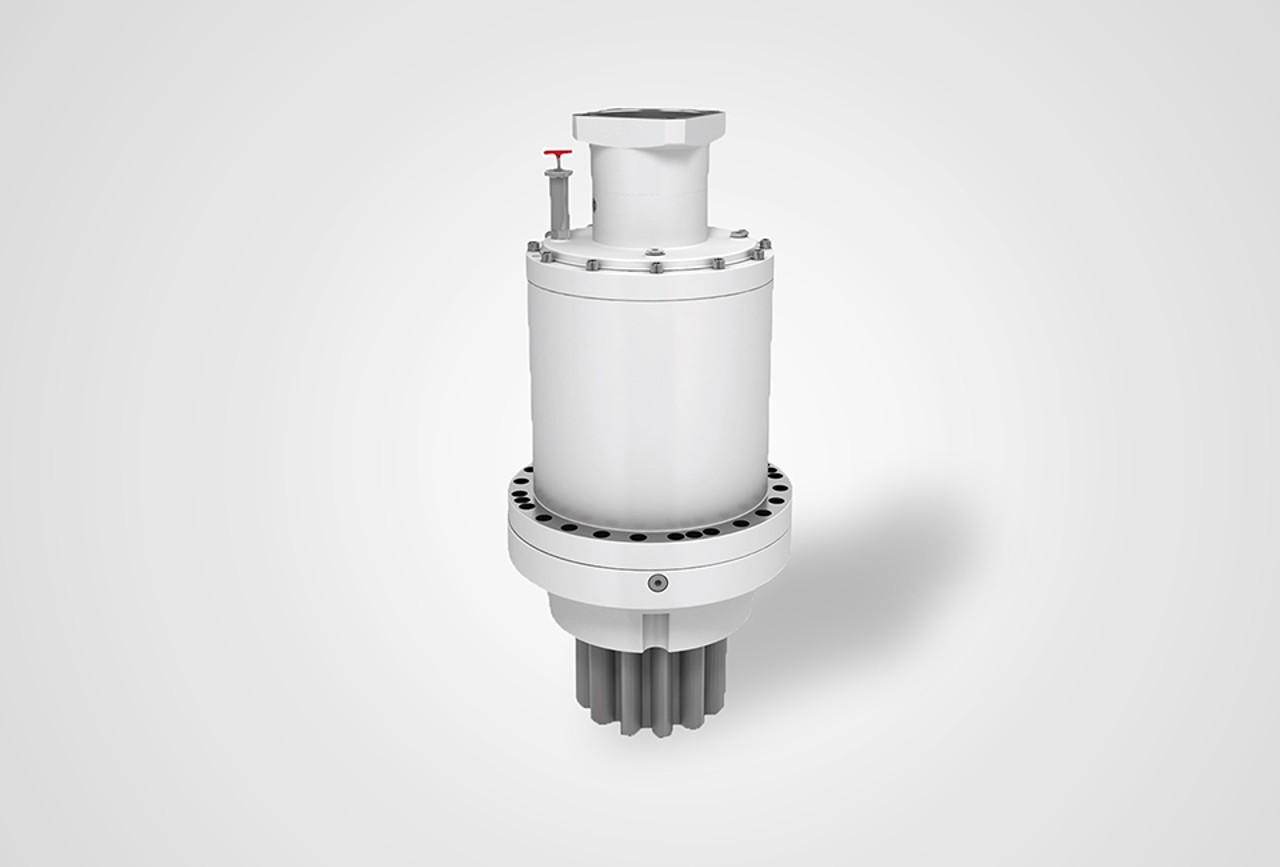

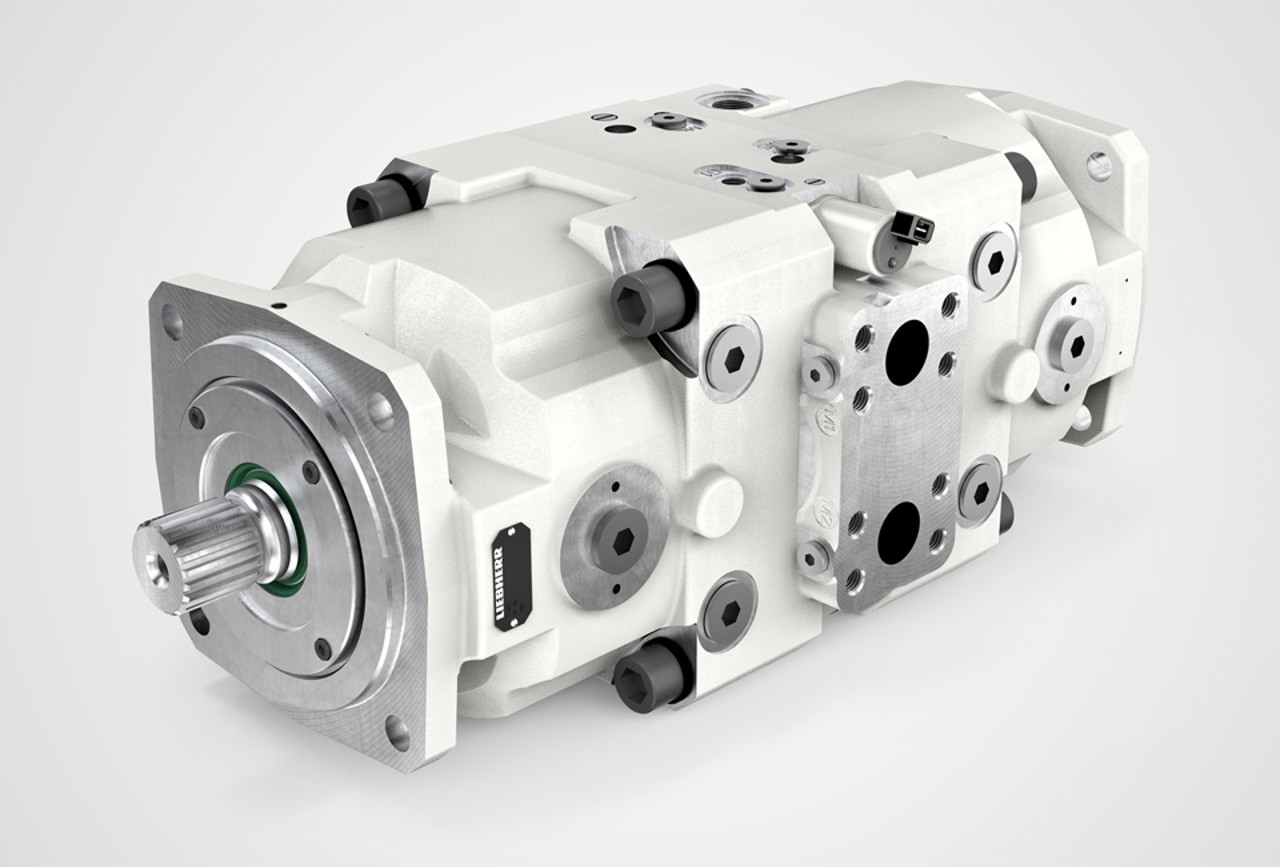

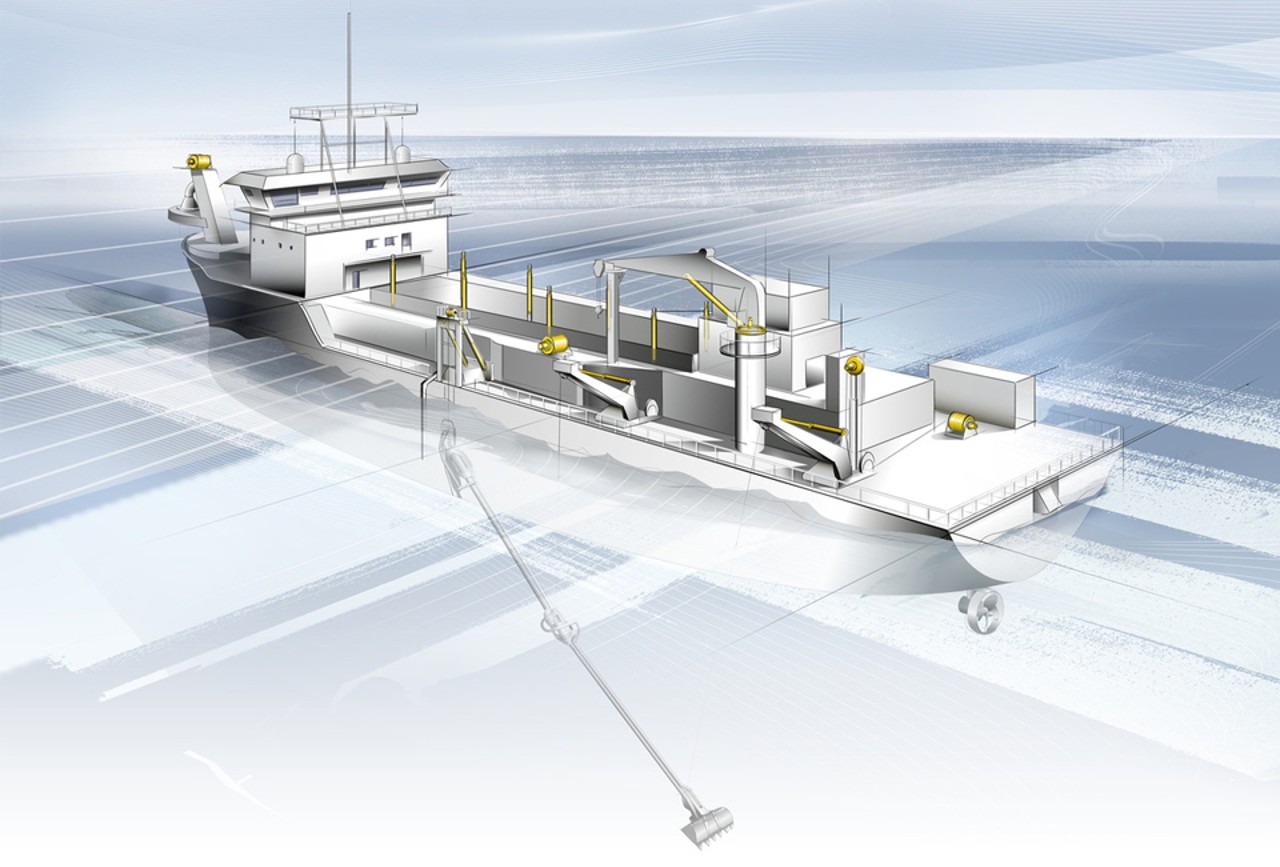

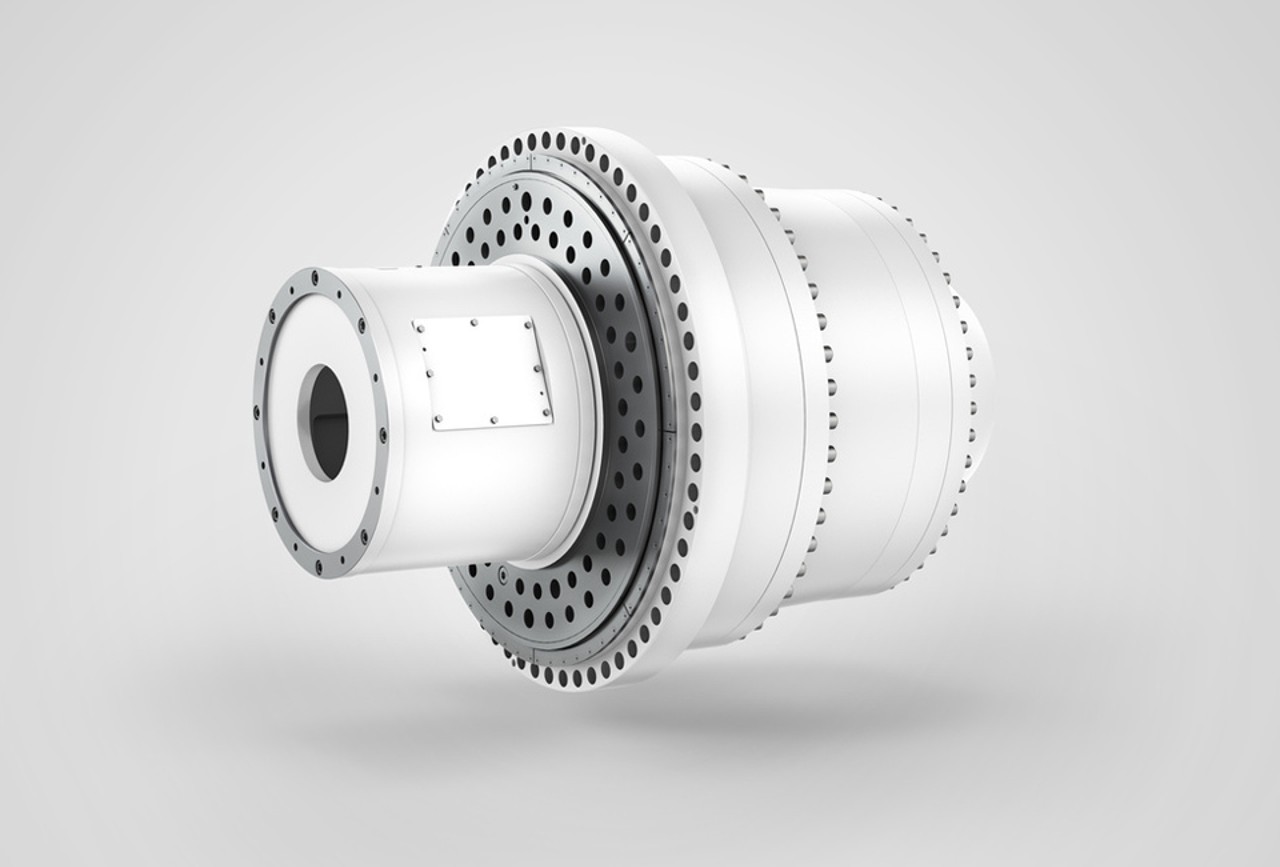

Drives for thruster

Made for harsh environments: The combination of Liebherr gearboxes, bearings and motors enables a perfectly harmonised system solution that meets the requirements of harsh environments.

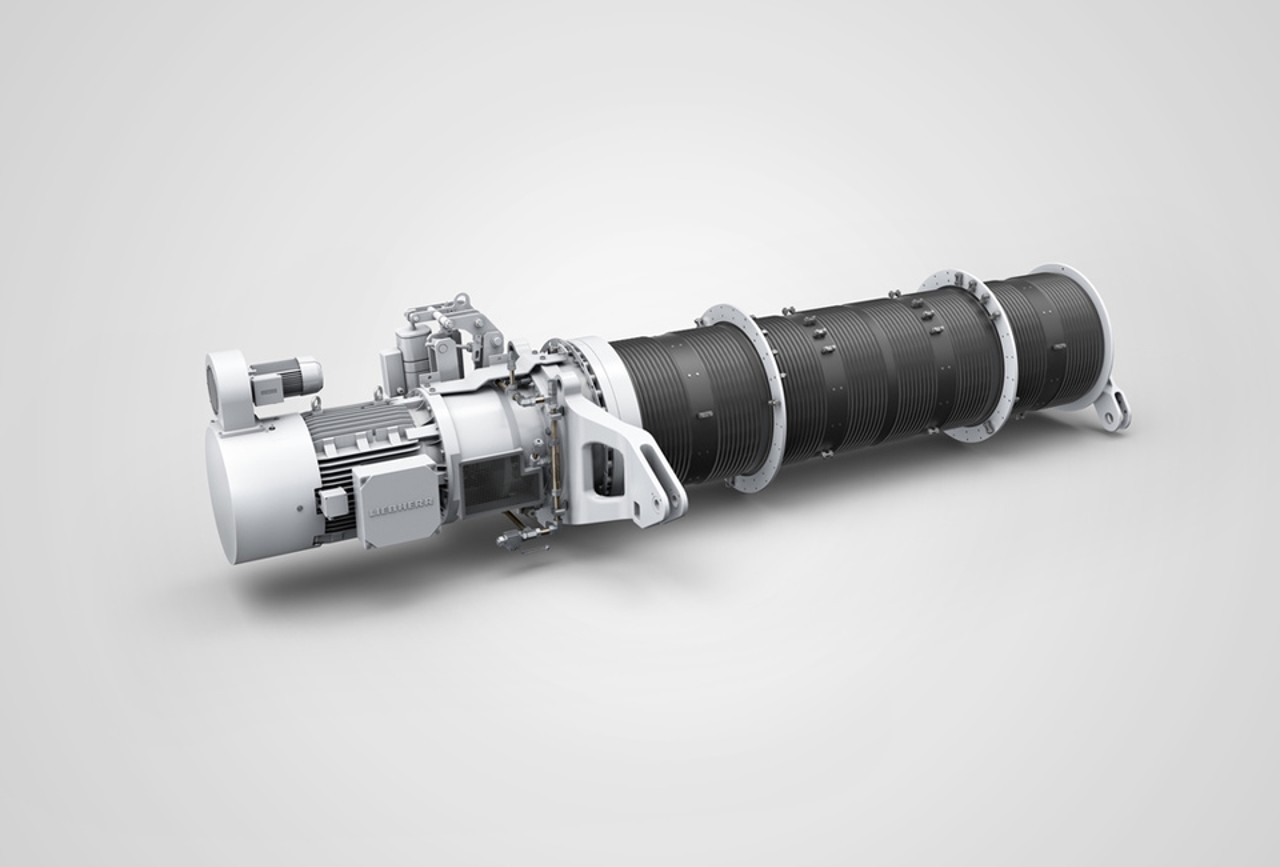

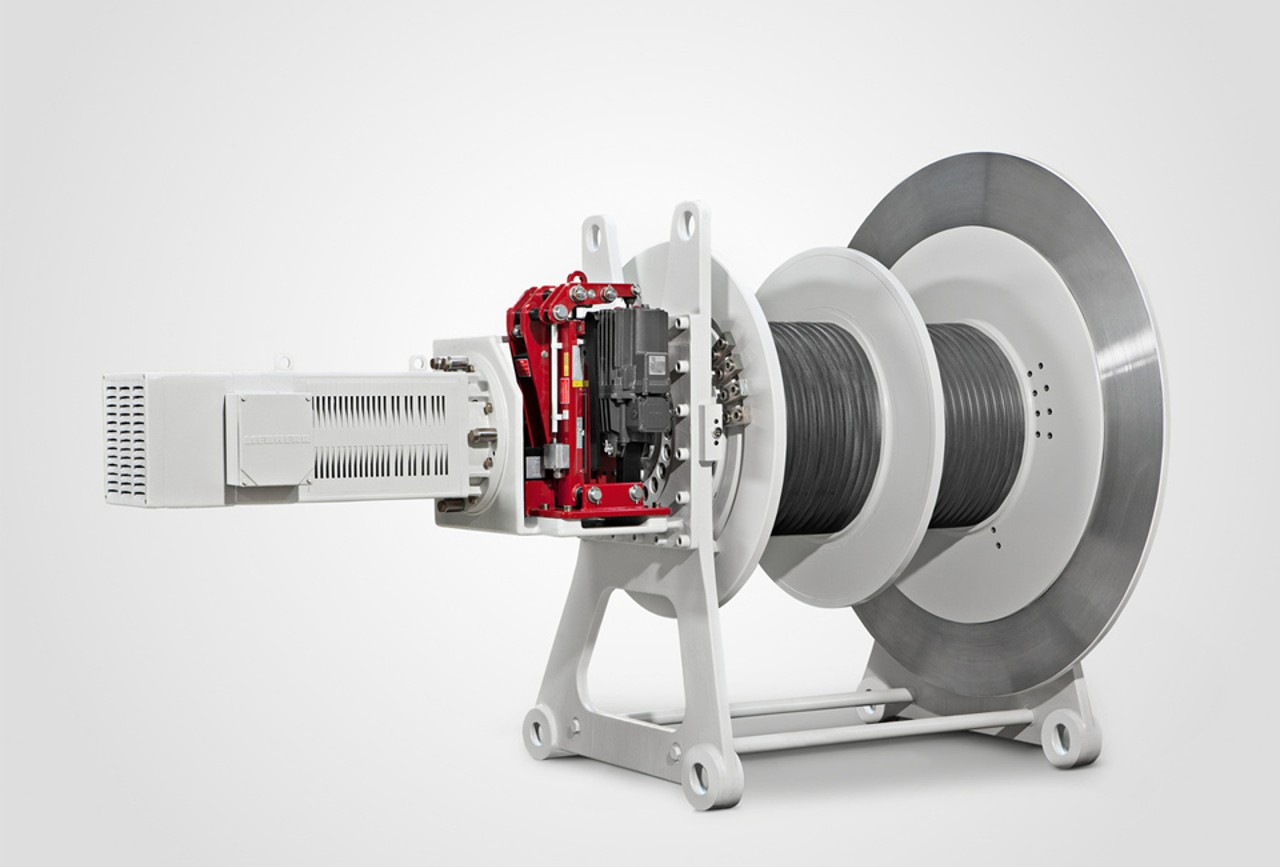

Drive solutions for ship and offshore cranes

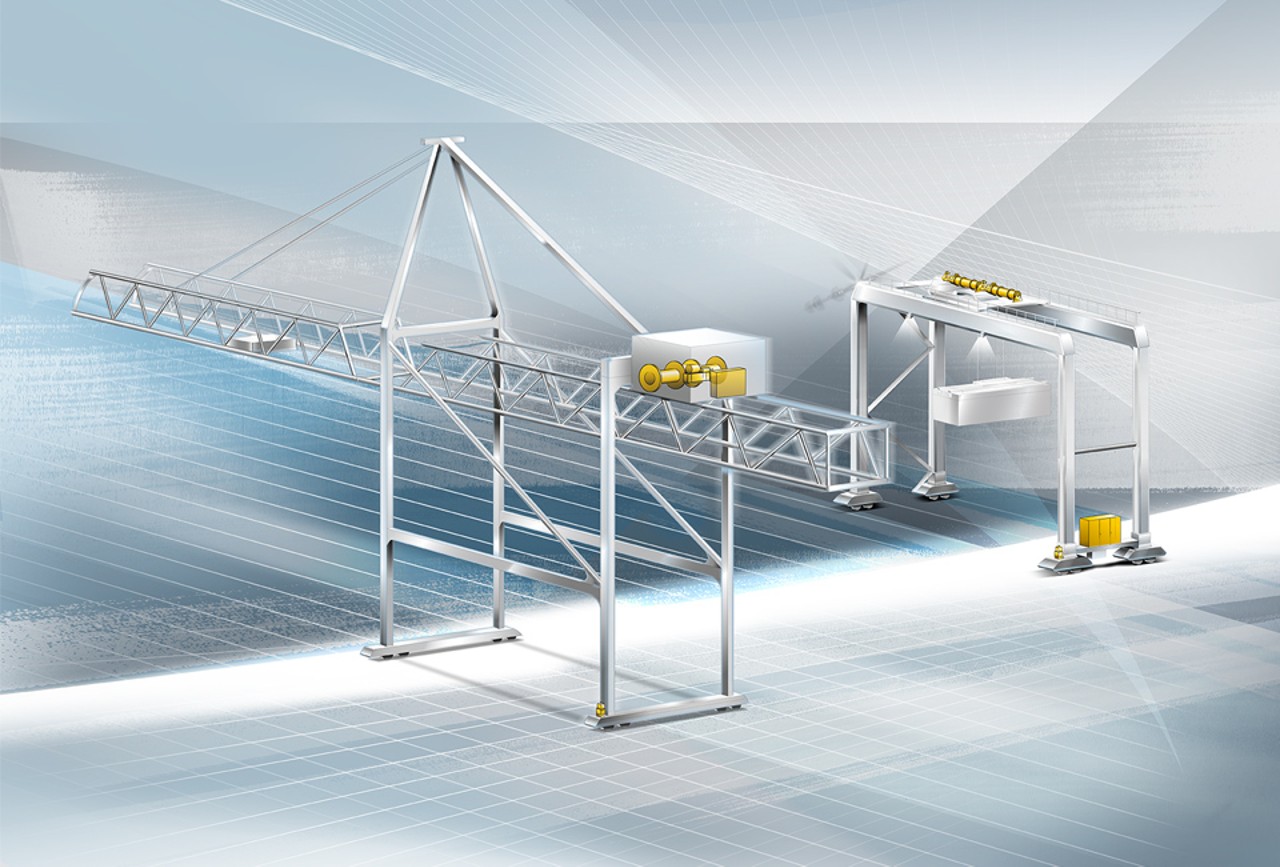

Drive systems for port cranes

Emission-free operations in harbours

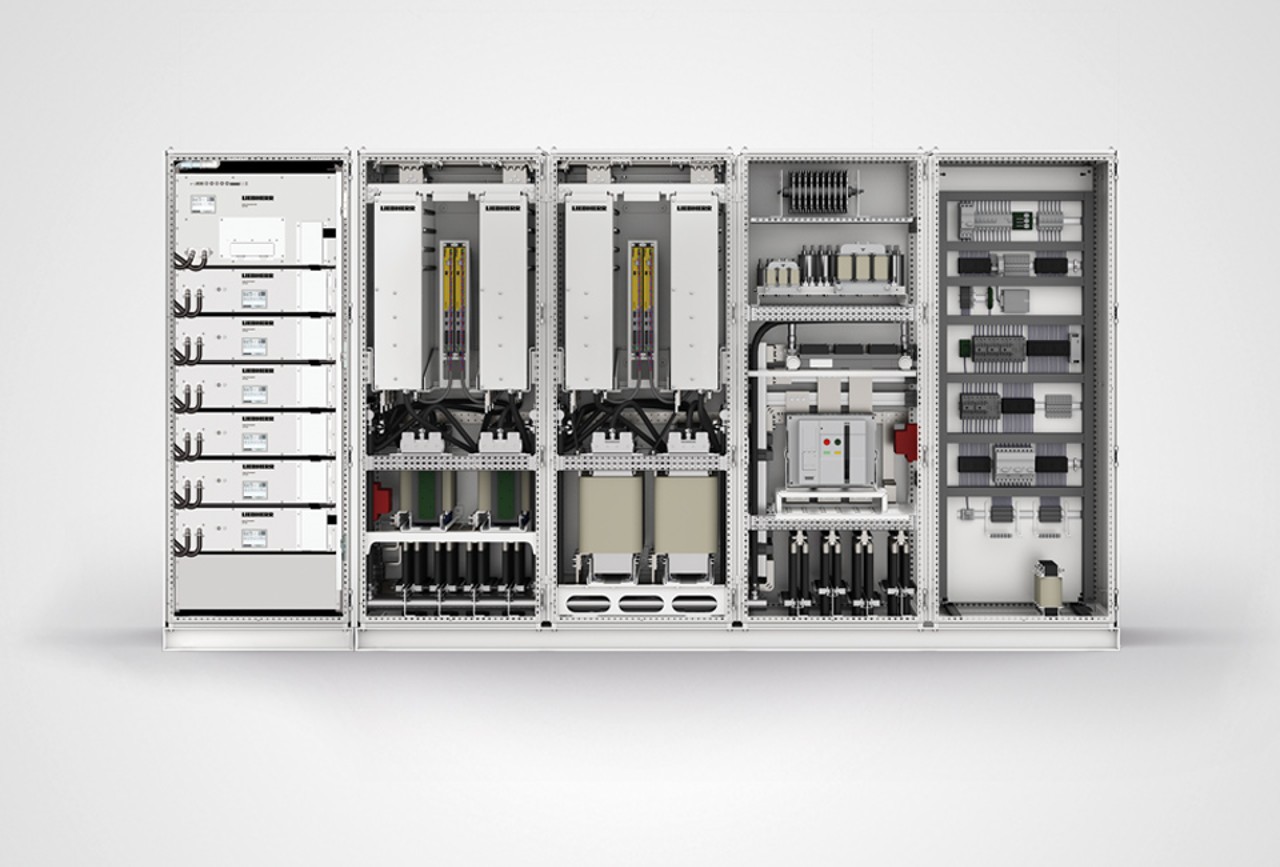

A significant share of total emissions in port cities come from ships and machines in harbours. To actively drive forward the reduction of emissions, Liebherr engineers develop most efficient solutions for hybrid drives and energy storage systems. Based on extensive research and testing, we address our customer´s challenges in the electrification of local operations.

Energy storage systems to cover “hotel loads” of ships: Applications used in ports or at anchor can be driven by fuel cells to reduce local emissions. Fuel cells have a high inertia reacting to load fluctuations, therefore applications with high peak loads require an energy storage system to cover for power peaks.

Local regulations for cities and harbours: Liebherr keeps up with the overall and regional developments in regulations for construction sites. Within projects, we can provide necessary information on recommendations for actions or specific laws.