Aerospace

Reliability of any equipment onboard of an airplane is an absolute must. At the company's own test centre, Liebherr aerospace components are therefore tested very rigorously prior to being dispatched and are certified in accordance with the highest industry standards. Furthermore, we endeavor the long-term availability of our products through our efficient obsolescence management.

Currently, the focus of development in the aviation sector is placed on "More Electric Aircraft (MEA)". With this approach in mind, aircraft can be made lighter and more fuel efficient and impress with high economy. The broad product spectrum of control and power electronics from Liebherr offers tried and tested applications for the electrification of aircraft.

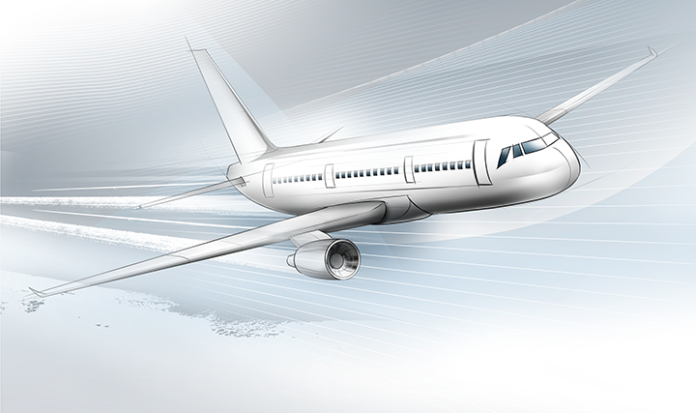

Liebherr components in aerospace

Be it helicopter or aeroplane - Liebherr offers a broad spectrum of electronic components for use in civil and military aerospace applications. The interactive diagram illustrates a typical range of products based on a commercial passenger plane as an example.

Aileron Actuator - Motor Control Electronics (MCE)

Find out more

Electric Heater Control (EHC)

Find out more

Elevator Actuator - Motor Control Electronics (MCE)

Find out more

Flap Active Differential Gear Box - Motor Control Electronics (MCE)

Find out more

Landing Gear Steering and Actuating Control Unit (LGSCU)

Find out more

Motor and Actuator Control Electronics (MACE)

Find out more

Air Conditioning System Control Unit (ACSC)

Find out more

Remote Electronic Unit (REU)

Find out more

Rudder Actuator - Motor Control Electronics (MCE)

Find out more

Slat - Motor Control Electronics (MCE)

Find out more

Spoiler Actuator Motor Control (MCE)

Find out more

Supplementary Cooling System Controller (SCSC)

Find out more

Transformer Rectifier Unit (TRU)

Find out more

Utility Computer (UC)

Find out more

Contact

Please contact us – we will answer your questions and put together an individual offer for you. If you need a component as a spare part for your Liebherr machine, please contact your local service partner.

Control technology and electronics

Liebherr can look back over many years of experience in the development and production of control and power electronics for the aviation sector. More than 100 series production items are already used in a whole range of different aircraft. Other services, such as engineering services, round off the portfolio.

- Safe and of high quality:

At the electronics test center in Lindau, our electronics solutions are rigorously tested using state-of-the-art test instruments and measuring equipment. Moreover, a range of certifications assure a consistently high level of quality standards. - Robust and durable

Electronics products from Liebherr are designed to endure even the toughest of environmental conditions for a long time and without damage. These include extreme temperature differences, vibrations and humidity. - Available for a long time

The long-term availability of our components is assured by consistent obsolescence management. In this way, we comply with the high industry standards of the aviation sector. - Individual

Based on standard interfaces, we offer an individual solution for every requirement. This makes diverse use in a whole range of different applications possible.

Products and solutions

Our product portfolio in the area of aerospace electronics ranges from high-quality flight control systems through refuelling systems to air management systems. Additionally, our customers worldwide rely on landing gear systems by Liebherr.

Control electronics

The control electronics from Liebherr work on the basis of high performance micro-controllers. For safety-critical applications, our experts develop equipment in the control/monitoring structure and design housings in accordance with customer requirements. Control electronics from Liebherr can be found not only in the area of flight and landing gear control systems but also in air-conditioning, cabin pressure control and de-icing as well as electrical systems.

Power electronics

Drive system and power electronics from Liebherr have already proven their performance in aircraft applications for many years. Motor-control electronics for electrical 4-quadrant drive systems in different performance classes support a wide range of different applications. Among these are electrical actuators or electrically-powered compressors for climate control.

Electronic Manufacturing Services (EMS)

Thanks to many years of experience in the development and production of its own electronic assemblies, Liebherr has become a competent partner in the area of EMS. The use of qualified staff and state-of-the-art technical equipment safeguards professional and high quality product manufacture. In addition to made-to-spec products, Liebherr offers different kinds of EMS ranging from development to after sales service. This is ranking Liebherr in a position to respond exceptionally well to customers' needs.

Contact

Please contact us – we will answer your questions and put together an individual offer for you. If you need a component as a spare part for your Liebherr machine, please contact your local service partner.

Test Center for electronics

Liebherr operates its own Test Center for electronics at Lindau. State-of-the-art testing and measuring equipment guarantees high product quality.