Deep foundation

Deep foundationReverse circulation air injection drilling (RCD)

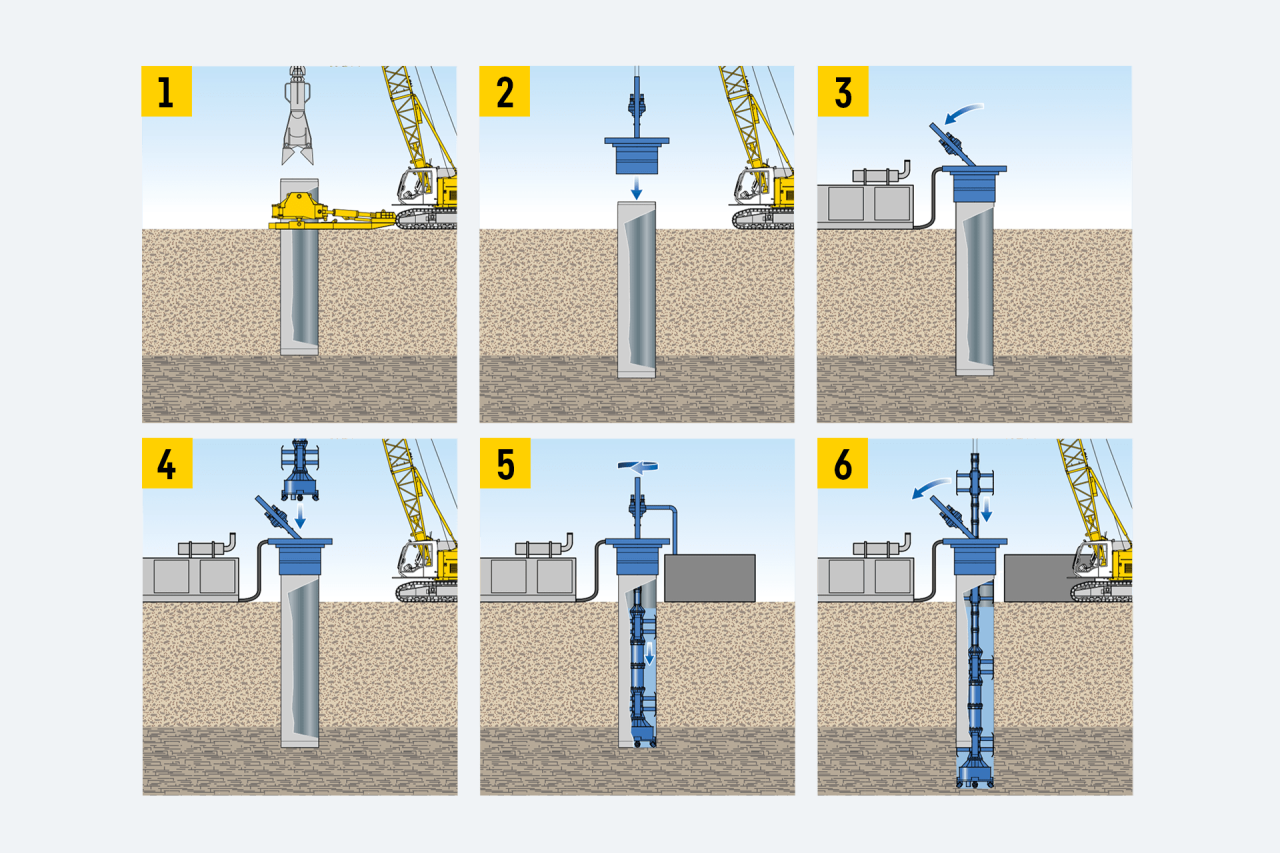

Reverse circulation drilling is a method of hydraulic circulation drilling to produce boreholes of up to approx. 3.2 meter diameter. In most cases drilling with hammer grab is first carried out. The soil is conveyed using the mammoth pump principle. The flushing current flows in the annular space between borehole wall and drill rod to the bottom of the borehole, from where the flushing current rises inside the drill rod conveying the cuttings with it.

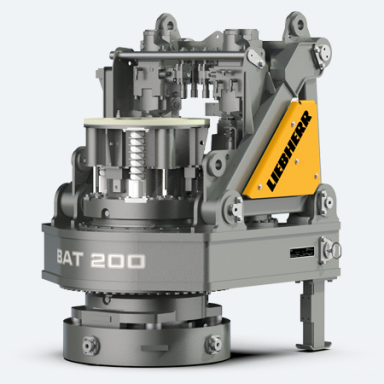

Machines

Results 1-2 of 2metric imperial