Operate

Convenient and efficient working with LiReCon

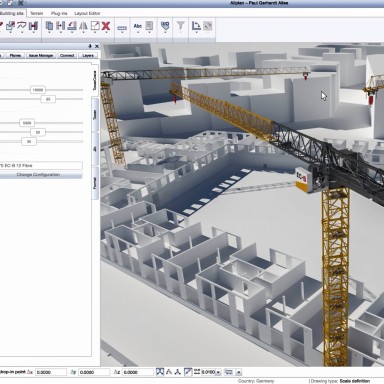

The construction site in transition

Managing a building site with a large number of people involved and interlinking processes is a complex task. Constant adjustments are necessary to be able to respond to the operational capacities of teams and changes in the contractor's schedule. Transport conditions for delivery trucks and the weather also need to be taken into account. Many such changes are still communicated via phone or paper printouts. But at the same time, there are efforts to increase efficiency and transparency, something referred to as lean construction. We’re addressing this trend in “Operate”. Here is a look at how we aim to make load handling on construction sites more efficient in terms of interaction between crane operators, site supervisors and signallers.

Clever advantages with LiReCon

A new approach to working!

First of all, we want to bring the crane operator closer to the site supervisor. Instead of staying in their cab, a crane operator will in future be able to work from the construction cabin on site. This has the result that the crane operator and site supervisor can interact directly with each other and consult on changes quickly. The change from crane cab to site cabin brings about a number of positive changes for crane operators. In addition to not having to climb to and from the crane cabin, they will have easy access to food and personal hygiene facilities. The change also makes the job itself more accessible to people not able to meet current requirements in terms of working at height and physical fitness. This is a point that will become more and more relevant due to the ongoing shortage of workers. Through LiReCon, we are significantly redefining what being a tower crane operator involves.

- Controlling of tower cranes from the ground

- Direct interaction between the site supervisor and crane operator

- Redefinition of the tower crane operator role

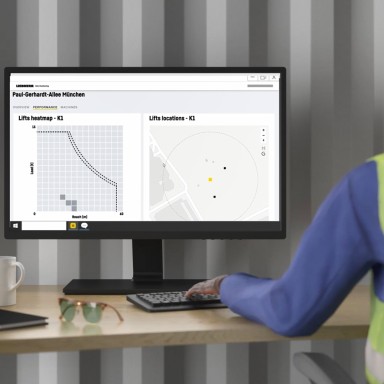

Always in the know!

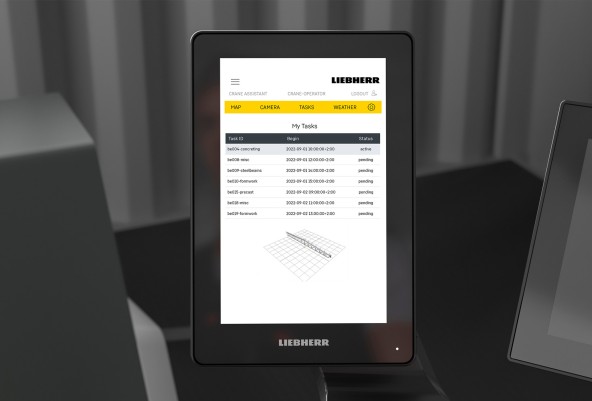

This communication is supported by a transparent task list for planning lifting activities on site. Key lifting processes can be made accessible to everyone, along with time schedules and load pick-up/unloading locations. Rescheduling due to new delivery times can therefore be communicated quickly and transparently to all parties at the touch of a button. This tool is, of course, available to all those involved, including site managers, supervisors and signallers, which helps to make construction site workflows more efficient.

- Task list for managing lifts

- Immediate transparency in case of delays

- Transparent overview for site supervisors, crane operators and signallers

More please!

When it comes to building site processes, crane utilisation during peak construction periods is certainly decisive for meeting set deadlines. Crane utilisation can be reduced before and after such periods. Liebherr's LiReCon teleoperation stand opens up completely new possibilities in this respect. Because with LiReCon, a diverse range of machines can be operated from a single control stand. Crane operators can easily switch from crane 1 to crane 2 from the site cabin to carry out a lift. It will also be possible to control other construction machines such as wheel loaders, excavators and crawlers – the technical basis for controlling such machines via a single control stand has been created.

• Control of diverse construction machinery via a single control stand

• Intuitive control concept “Intusi”

Safety all the way!

Safety is always a top priority. Because every lift on site has to be carried out by the crane operator in a way that ensures safe working, especially for the riggers and others working down on the ground. And that needs to happen regardless of the weather. Consequently, we see the expansion of supportive assistance systems that simplify crane operation as a key priority for site safety. This isn’t just restricted to remote-control operations via LiReCon. Every construction site, every crane and every lift can benefit from our new features.

• Optimised safety through supportive assistance systems

• Teleoperation with focus on safety & security

• Easier crane operation, even in adverse conditions

Construction machinery operation – key terms

Take a look at the main buzzwords used in digital construction planning.

- Lean Management

- Teleoperation

- LiReCon

- LiReCon

Lean management means creating value without waste. The aim is to optimally coordinate all activities that are necessary for creating value and to avoid unnecessary processes.

Lean management means creating value without waste. The aim is to optimally coordinate all activities that are necessary for creating value and to avoid unnecessary processes.

Contact

If you have questions about planning with Liebherr Tower Cranes or you’re interested in a Crane Information Model, please don’t hesitate to contact us via email or give us a call!

Tobias Scholz

Head of Market Management

Liebherr-Werk Biberach GmbH

Phone: +49 (7351) 414274