Vertical Line Finder

Vertical Line Finder helps the crane operator to successfully avoid unwanted load sway due to diagonal pull when lifting a load. When this is activated, the crane automatically controls the slewing gear and trolley and ensures that the load hook is always optimally positioned above the centre of gravity. The automatic aligning of the hook in relation to the load guarantees that the load is always lifted vertically; angled lifting is prevented.

This reduces the risk of swaying and minimises the risk of collisions, which in turn increases safety for those working on site and for sensitive components. Vertical Line Finder is also a huge plus in terms of convenience for the crane operator as the assistant takes over the precise, vertical positioning of the load hook.

Use examples

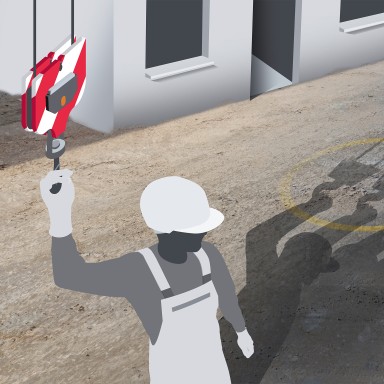

Lifting a load without hoist rope sway

When lifting sensitive components like glass fronts, prefabricated façade elements and other sensitive materials, there is a risk of diagonal pull causing the load to sway and cause damage.

Solution: Vertical Line Finder

The assistant ensures that the load is lifted vertically with precision, preventing diagonal pull and sway. This minimises the risk of collisions, which increases safety on site and protects sensitive components from damage.

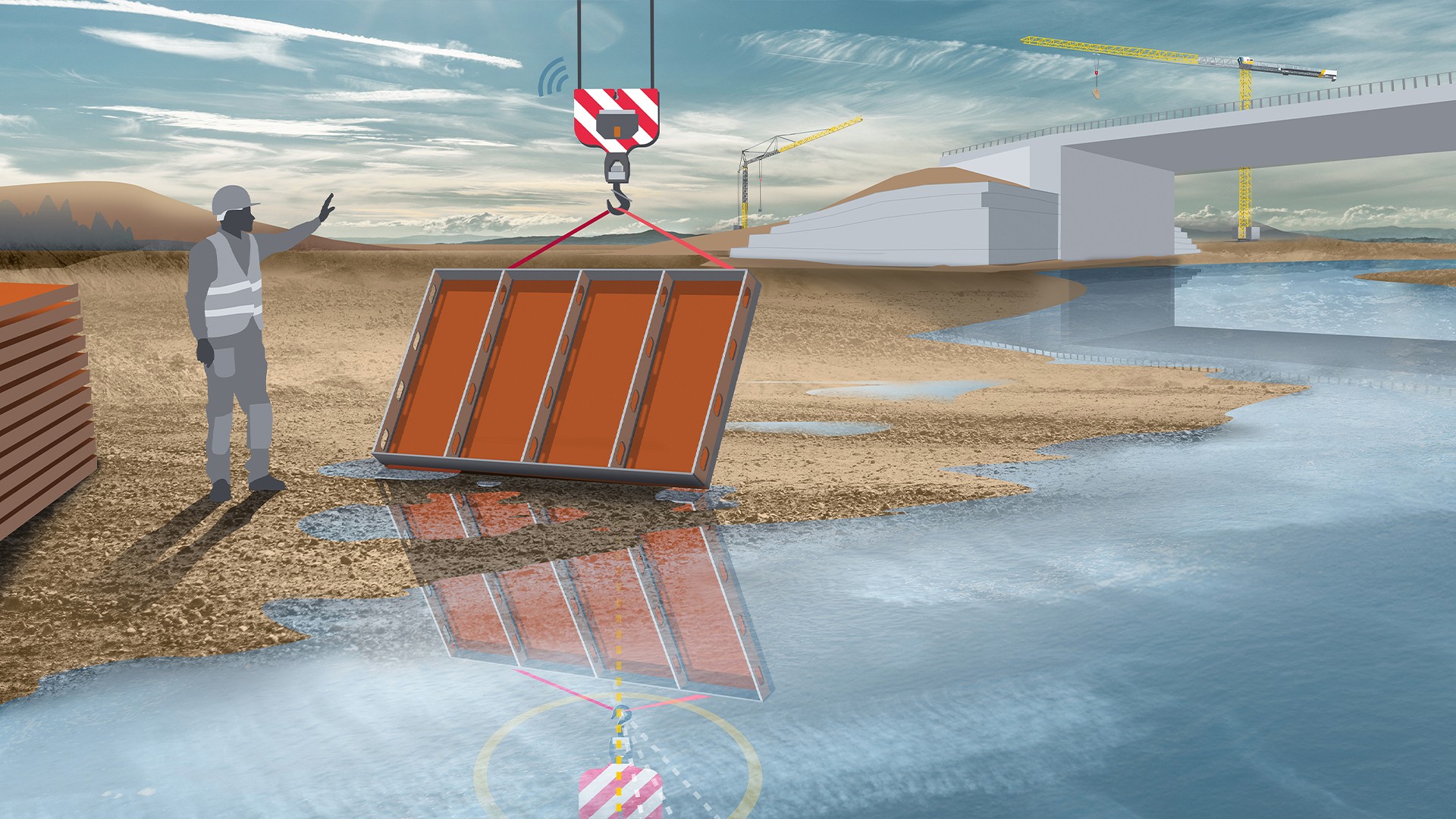

Raising horizontal components e.g. formwork and precast walls

Formwork and precast walls are often delivered lying flat on a truck or stored flat on site. Raising such elements and building components with large surface areas without sway requires increased concentration and operational effort. The operator has to manually adjust the trolley and slewing gear according to the inclination of the component.

Solution: Vertical Line Finder

The assistant automatically takes over the adjustment of the two drives so that walls are lifted evenly and without diagonal pull. This results in the more stable handling of such loads and minimises the risk of damage. It also makes things easier for the operator by taking away the need for manual adjustment.

Lifting long or unevenly distributed loads

Long or unevenly distributed loads such as steel beams, formwork and flat-lying precast walls can easily start to lean when lifted, which encourages load sway and makes handling more difficult.

Solution: Vertical Line Finder

The assistant automatically corrects the lifting movement so that the load is lifted evenly and without diagonal pull. This ensures a more stable handling of such loads, reduces the risk of sway and minimises the risk of collisions.

Availability

Vertical Line Finder is available as an option for the 25 L & 33 L and the 43 K, 61 K & 91 K.

Other assistance systems

Notes on use:

- The crane operator is responsible for lifting and moving the load safely. The assistance systems are there to provide support. Liebherr recommends that crane operators undergo crane operator training.

- The assistance systems are not always useful in all lifting situations, e.g. in confined areas, which is why they can be activated and deactivated at any time.