Sway Control:No additional sensor hardware is required.

Sway Control Plus: An IMU sensor on the hook block captures the inclination and angular velocity of the load hook.

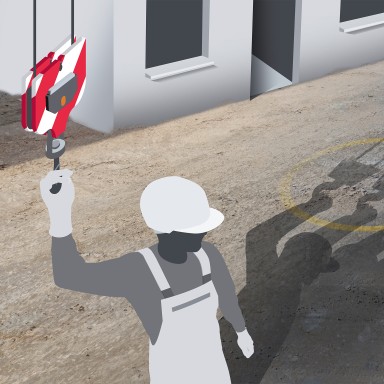

Sway Control & Sway Control Plus

The assistant supports the crane operator with sway-free operation. Hook block sway is actively corrected in both slewing and trolley directions.

Sway Control Plus utilises an IMU sensor system on the hook block, which detects inclination and angular velocity. This means that the system can also recognise and eliminate sway that already exists before the system is activated or is caused by external influences, e.g. wind.

The assistant is particularly useful for less experienced and occasional crane operators, given sufficient space. It supports operators with limited experience by automatically damping sway, thereby increasing safety and efficiency.

Use examples

Less experienced crane operators

Less experienced crane operators often find it difficult to address or avoid sway correctly. This is a common problem, especially on construction sites where operators don’t work with the crane regularly.

Solution: Sway Control (Plus)

The assistant supports operators with limited experience by automatically damping and eliminating sway, thereby increasing safety and efficiency. The system simplifies the training of new operators and reduces mistakes.

Less strain on the operator

Crane operators often have to focus on their work over long shifts, which can lead to fatigue and a decline in performance. Manually addressing sway is especially demanding and requires a high level of concentration.

Solution: Sway Control (Plus)

The assistant takes the strain off the operator by automatically damping and eliminating sway. This reduces the physical and mental demands on the crane operator and helps to improve work safety.

Simultaneous operation of all drives

The crane operator usually operates crane drives individually to prevent the load from swaying. But this slows down the work process and reduces efficiency as the load isn’t transported directly to its destination.

Solution: Sway Control (Plus)

The assistant allows the crane operator to utilise all crane drives simultaneously, in a controlled manner and without load sway. This significantly shortens lifting times and increases productivity as there are no unnecessary interim stops and the load can be moved to its destination via the shortest route.

Availability

Sway Control is available as standard for the 25 L & 33 L and the 43 K, 61 K & 91 K. Sway Control Plus is available as an option for these models.

Other assistance systems

Notes on use:

- The crane operator is responsible for lifting and moving the load safely. The assistance systems are there to provide support. Liebherr recommends that crane operators undergo crane operator training.

- The assistance systems are not always useful in all lifting situations, e.g. in confined areas, which is why they can be activated and deactivated at any time.