Recycling process

Recycling process

First steps for the circular economy

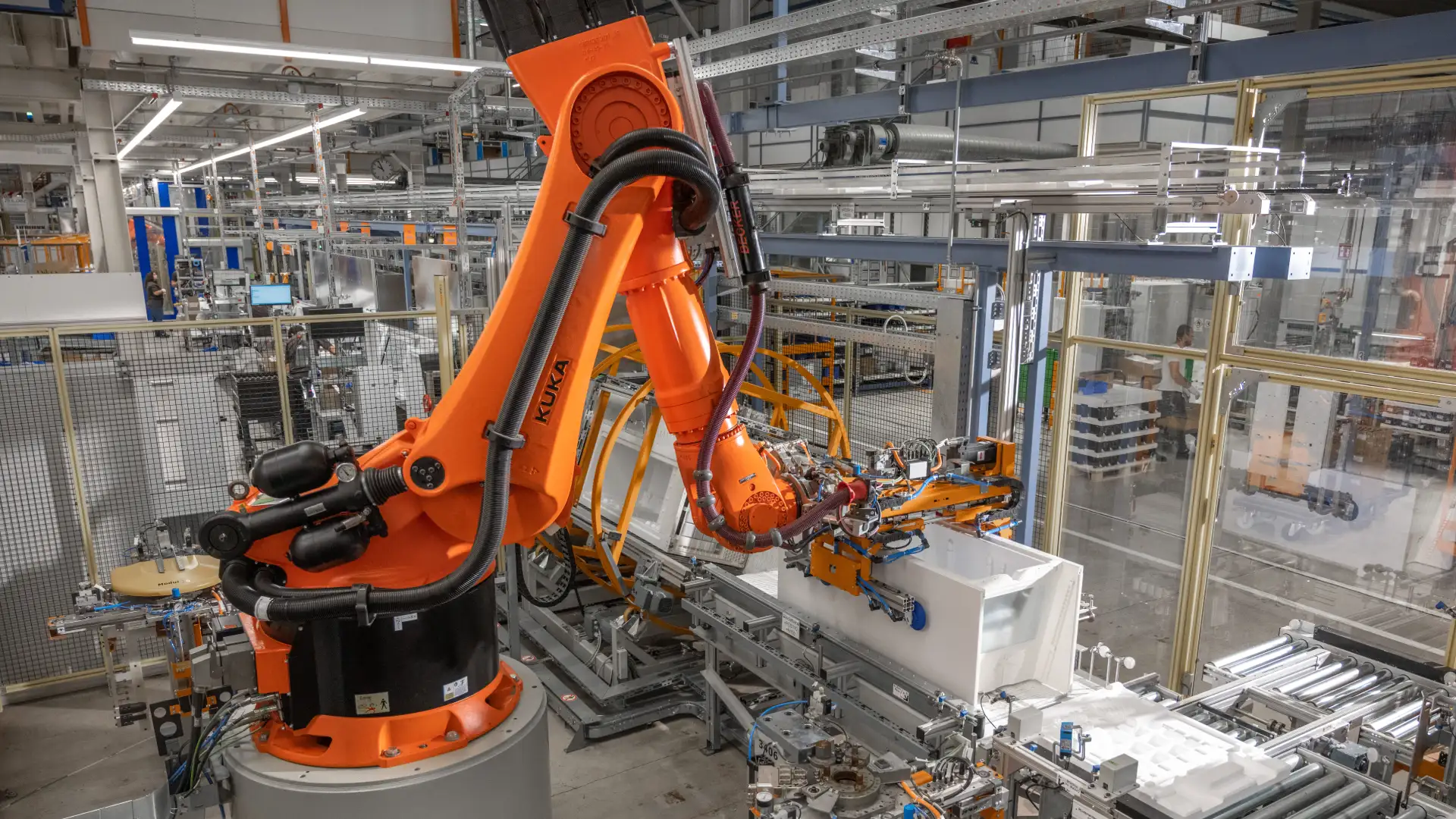

The processing of fridges and freezers follows a structured process to recover valuable materials and safely dispose of harmful substances. The process consists of two stages, with step 1 focusing on dismantling and the removal of hazardous components and parts. These specialised steps ensure compliance with industry standards while maximising resource recovery.

The recycling processfor appliances

Recycling roadblocks

While valuable materials like steel, aluminium, and copper can be efficiently recovered, processing plastics and insulation foam remains a major challenge. The variety of plastics poses a significant hurdle for pure-grade sorting and high-quality recycling, preventing reuse at the same standard in new products. We prioritise single-variety plastics when processing allows. Plastic components over 50 g and rubber parts over 25 g are marked to aid recycling. Where possible, processing waste is collected, ground, and reintegrated into production, while non-recyclable plastics are sorted and sold. Insulation foam cannot be recycled and is instead used for thermal recovery, losing the material permanently.

Corporate Responsibility documentation 2024

For more comprehensive insights, data and in-depth details, see our full Corporate Responsibility documentation.