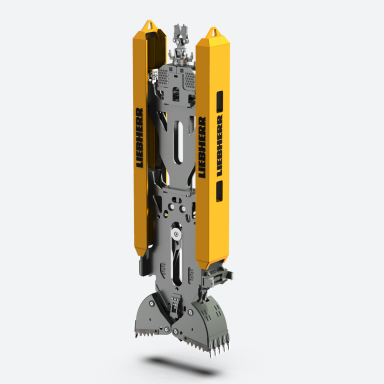

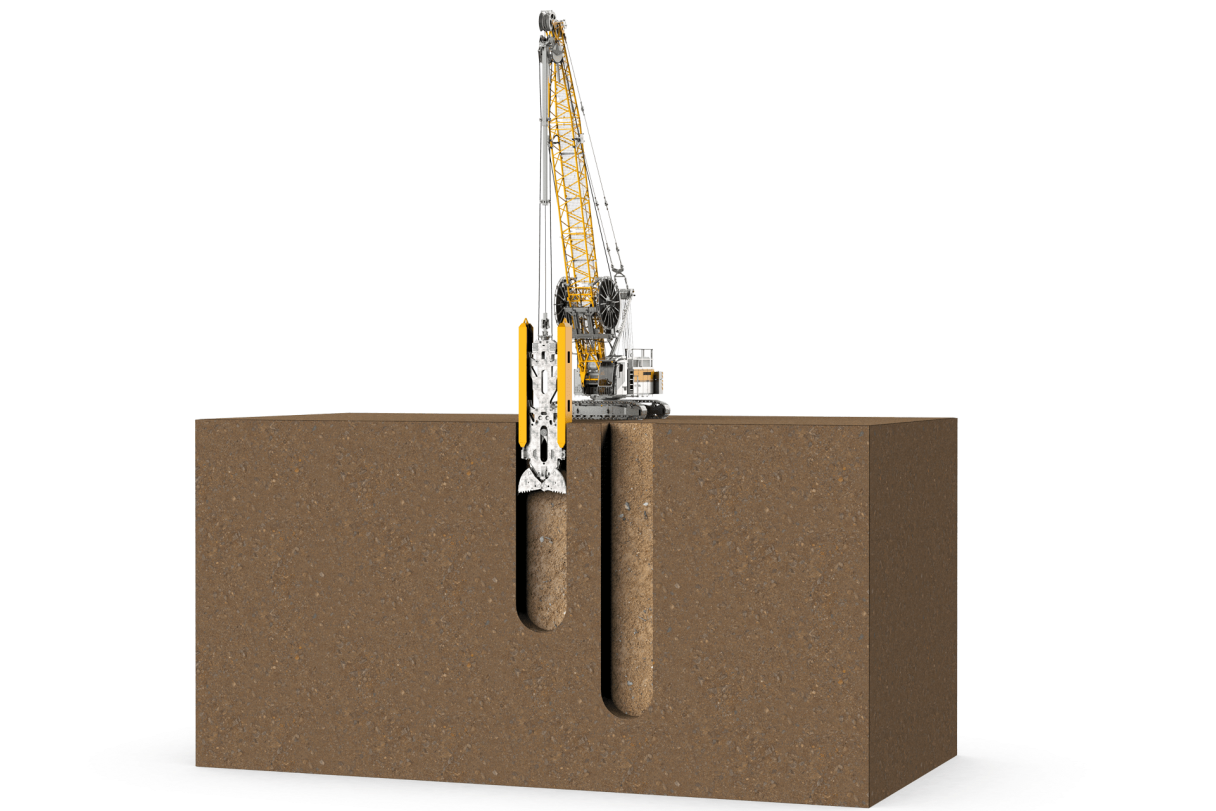

If slurry walls are installed with a grab, a two-jaw slurry wall grab suspended on a duty cycle crawler crane excavates the slurry wall panels. Mechanical grabs are opened and closed via rope, hydraulic grabs via hydraulic cylinders. Hydraulic grabs can additionally be fitted with flexible guiding strips on the grab frame which allow to align the grab within the trench.

01/07

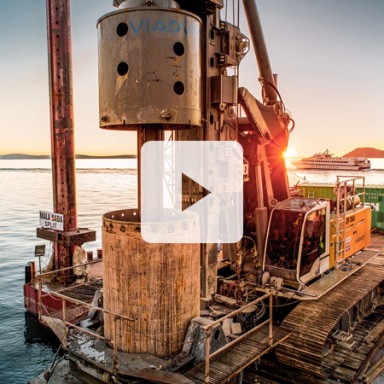

Video: Slurry wall grab

Duty cycle crawler cranes from Liebherr excavating slurry walls with mechanical or hydraulic slurry wall grabs.

Machines

Results 1–6 of 7

1

2

Job reports

01/04