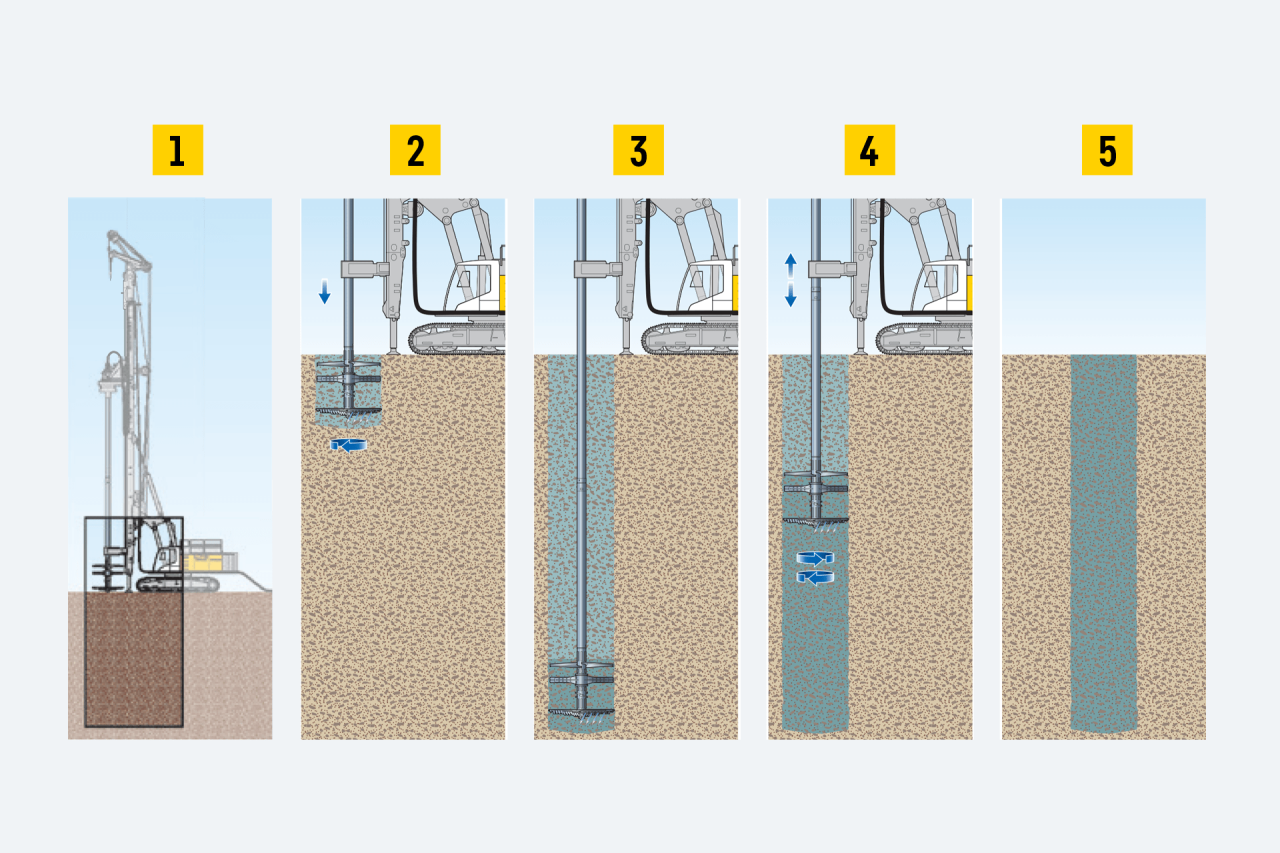

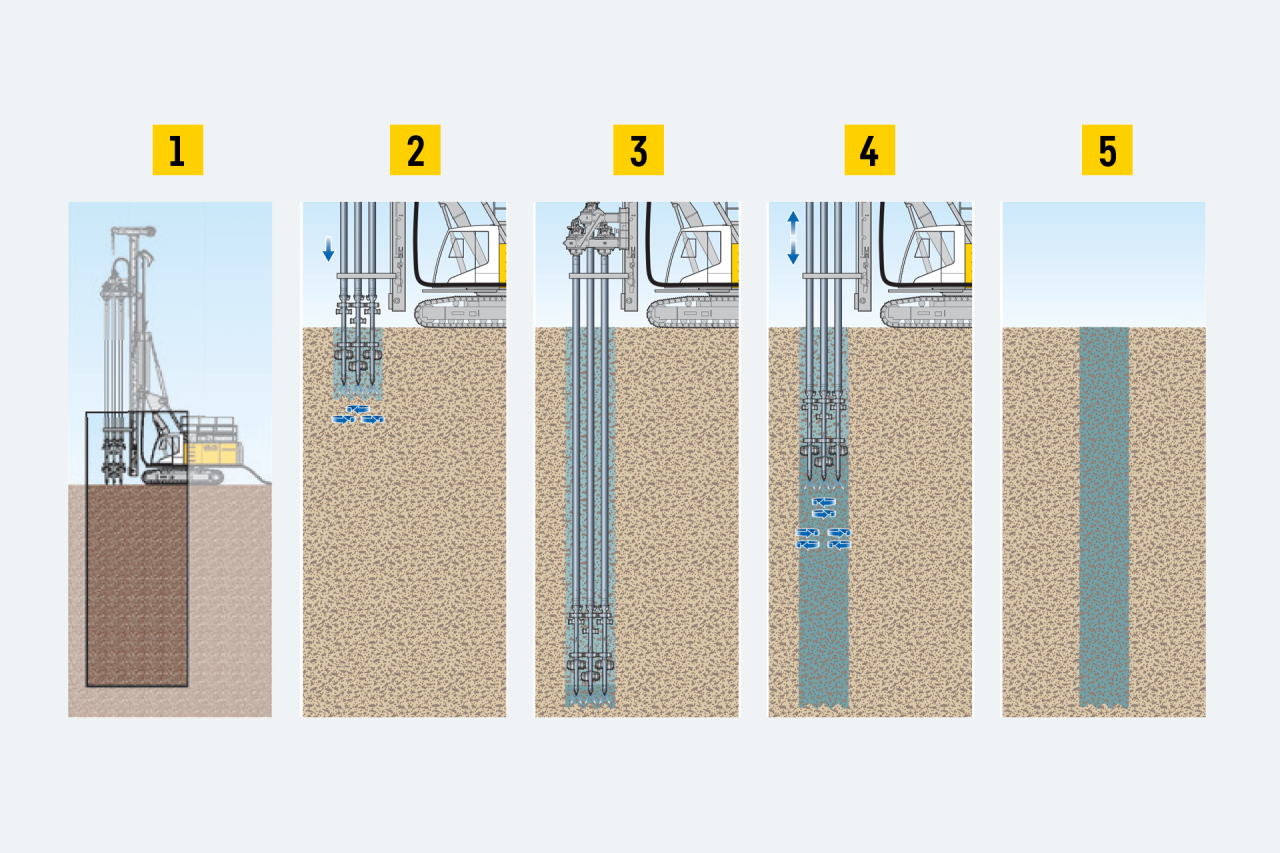

For wet soil mixing the mixing tools rotate around the vertical axis of the mixing shaft. The tools break up the soil matrix and mix the suspension with the soil. The binding agents used are usually cement types mixed to a suspension by adding water.

01/02

01/07

Video wet soil mixing

The video shows the production of soil mixing elements using the wet soil mixing process.

Machines

Results 1–6 of 13

1

2

3