FlexChamfer: Maximum flexibility for deburring and chamfering gears

FlexChamfer

Economical deburring and chamfering even for small batch sizes

As power density increases, more focus is being placed on machining the face edges of gears. Innovative chamfering technologies are required in order to achieve the quality requirements and precise chamfer shapes that are demanded. One promising technology is the precise ChamferCut process, which produces the exact chamfer shape. However, conventional chamfering technologies reach their limits with small batch sizes and difficult component geometries. Particularly in the case of cluster gears, ChamferCut cannot machine all the gear positions.

The patent-pending FlexChamfer process is ideally suited for small batch sizes, both for simple and difficult workpiece geometries. In contrast to ChamferCut, which has its strengths in larger batch sizes, FlexChamfer allows flexible and cost-efficient production even for small and medium batch sizes. The universal milling cutters used are cost-effective and can be changed quickly and easily without the need for time-consuming retooling. This means that even small batches can be processed very economically.

Highlights

The advantages of FlexChamfer at a glance

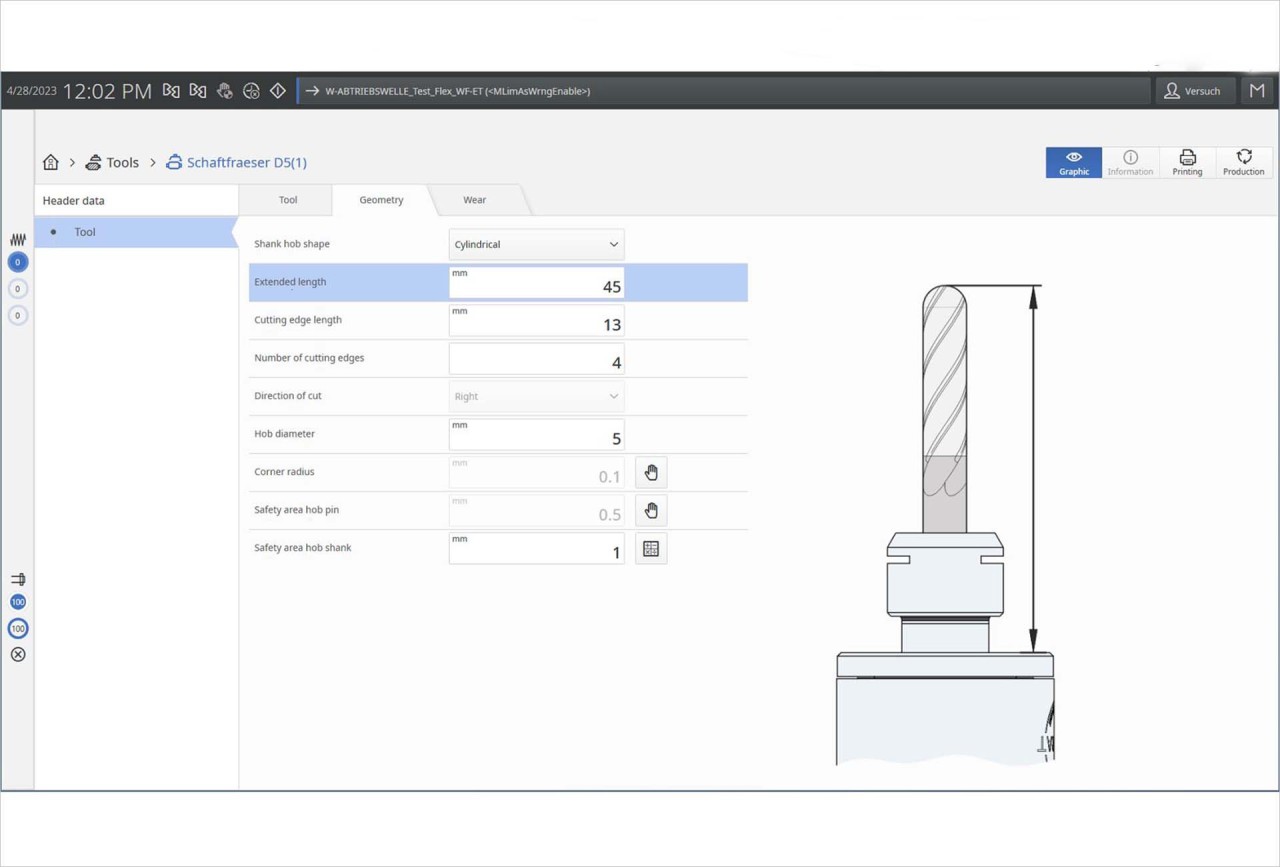

- CNC-controlled refinement of chamfering with carbide milling cutters

- Generation of variable chamfer shapes with standard catalogue tools

- Especially suitable for external gears with or without interfering contour, as well as shafts and internal gears

- Can be used in hobbing, shaping and skiving machines

- Takes place during machining (depending on the cycle time for gear cutting)

- Ideal for small and medium batch sizes

- Quick set-up and changeover

- Wet and dry machining

Video

Applications: chamfering with FlexChamfer

FlexChamfer can be used for various technologies:

Gear hobbing

Liebherr has manufactured highly productive gear hobbing machines for decades. With its wide range of machine types, Liebherr can serve the needs of customers from a wide variety of industries from automotive to wind turbine manufacturers.

Gear shaping

Liebherr gear shaping machines are used in special applications. We design individual manufacturing solutions for our customers.

Gear skiving

With Liebherr gear skiving machines, you get the process, tools and machine including tool changer and automation from a single source.