Liebherr Rough terrain cranes

Safety is built into our LRT rough terrain cranes

Wherever you need to make your next lift, our rough terrain cranes are the safest choice for the job. Featuring the highest possible level of standard safety features available on a rough terrain crane, our LRT® cranes help you to grow your business while increasing jobsite safety.

Where others offer options, we deliver safety right from the start. Our rough terrain cranes are the perfect fit for many industries. Off-road capable, powerful and robust, and embody the utmost level of safety features.

Safety comes as standard

VarioBase®

The standard VarioBase® support base means more safety, greater flexibility on site and better performance.

As a result of increased lifting capacities when hoisting over the support, the crane can hoist loads normally reserved for the next higher crane class. The crane software identifies the machine's precise center of gravity and the tipping edges and then sets the two relative to each other.

This means higher lifting capacity and greater outreach. Ensuring safe and easy operation even in constricted work areas where full outrigger extension is not possible.

Better overview

No blind spots

The LRT® cranes feature an extra wide crane cab. The standard cab is 20° tiltable backwards to ensure a direct view to the load while hoisting. To climb into the cab safely, a sideward extendable running board comes also as a standard.

All controls are clearly layed out and self-explanatory.

Just simple

Safe and easy operation

To ensure an easy handling in operation, we have included the automatic support leveling of the crane. By this, we also increase the safety of crane operations, ensuring the crane is always leveled during a job.

And we have put in much more: intuitive controls for crane operation ensures fast learning for the crane driver.

On the safe side

Global Safety Charts

Worldwide operations in mind, our LRT® cranes come with standard global load charts according to ASME, EN, GOST, AS.

Therefore we support global safety regulations right from the start.

Areas of application

Construction

Oil and gas

Mining

Wind energy

1001 different loads:

Construction industry

No matter what you need to lift and where, our rough terrain cranes are safe and easy to handle.

Whether it is lifting construction materials in the yard, containers onto trucks, scaffolding on a construction site or steel beams up to the roof – the Liebherr LRT® cranes are flexible and easy to use, even for operators new to the Liebherr rough terrain cranes.

Where safety can’t be an option:

Oil & Gas sector

Refineries, power stations, petrochemical plants or other installations of the oil and gas sector are like home for our rough terrain cranes. Where safety can not be an option, the LRT fits in perfectly.

Safe and easy handling, especially for operators new to the Liebherr LRT® cranes is guaranteed by many safety features, providing the maximum possible safety on and around the crane.

Let’s get big:

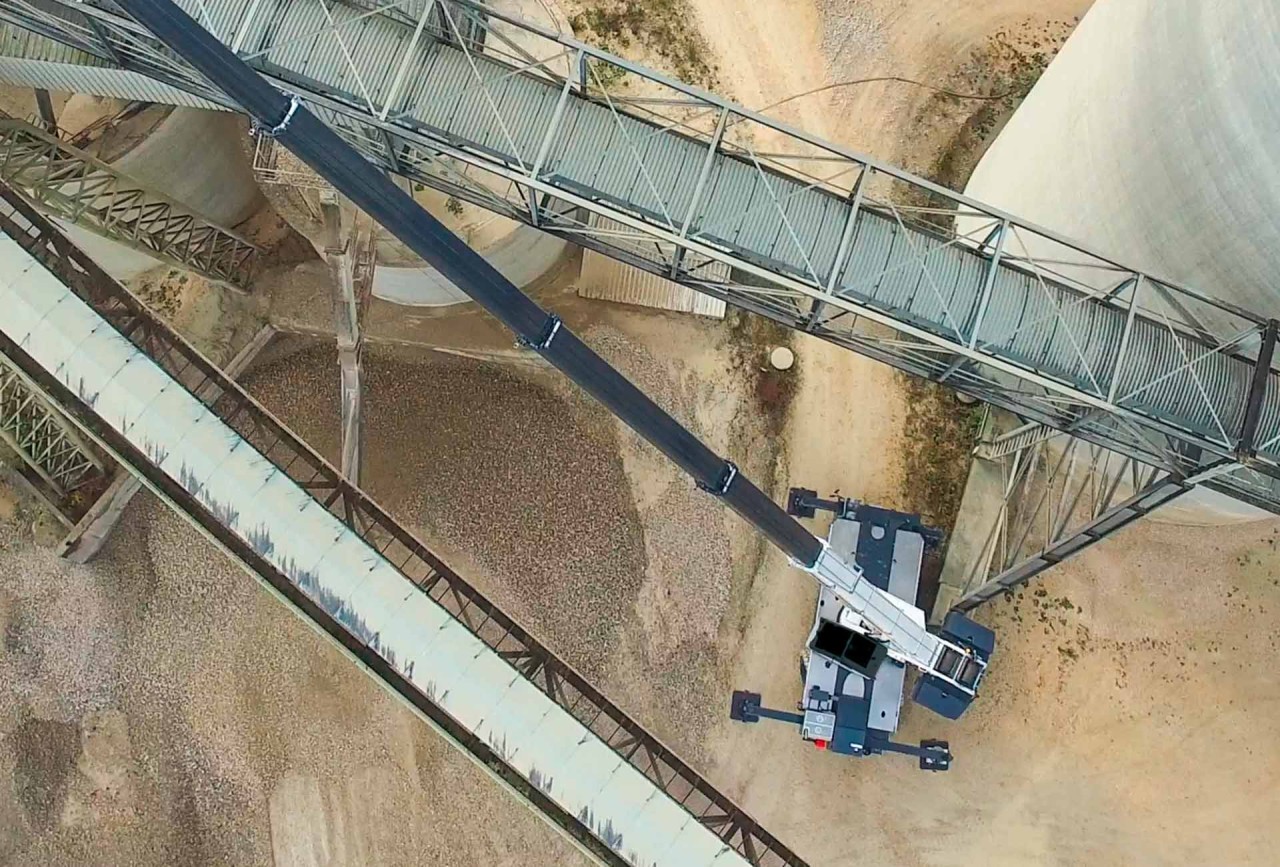

Mining industry

Changing excavator buckets, maintenance on mining trucks or the setup of new installations in a mine – this is where the LRT® crane comes in handy. With a great range of standard configurations, the rough terrain cranes can handle everything and can be operated by everyone.

And with all safety features on board as a standard, our LRT keeps your multimillion dollar business safe for sure.

Go with the breeze:

Wind industry

Maintenance work in a wind park, assembly of larger cranes for the erection of wind turbines or easy lifting of the construction material – the LRT is ready for everything in the wind industry no matter the ground conditions: marshy, mountainous, or flat land. Our rough terrain cranes ensure successful operations with the highest possible safety on rough terrain cranes as a standard.

And with the easy handling of the crane, also untrained operators are able to make lifts within a minute.

A walk around tour of Liebherr Rough terrain cranes

Intelligent crane control

LICCON

Our Liebherr Computer Control - or LICCON - crane control software and hardware is developed in house. We continue to refine LICCON, which is perfectly integrated into the machine, ensuring reliable crane operations anywhere and anytime.

Increased safety as a standard

VarioBase®

VarioBase increases efficiency for crane operations by ensuring higher lifting capacities. If the load is hoisted over a support, the risk of tipping is lower than during hoists to one side. This means that the crane software can permit a higher lifting capacity. All load charts are calculated live during the job through the LICCON crane software.

The increases in lifting capacities mean that ballast transport is simply not required for many crane jobs.

Proven over decades

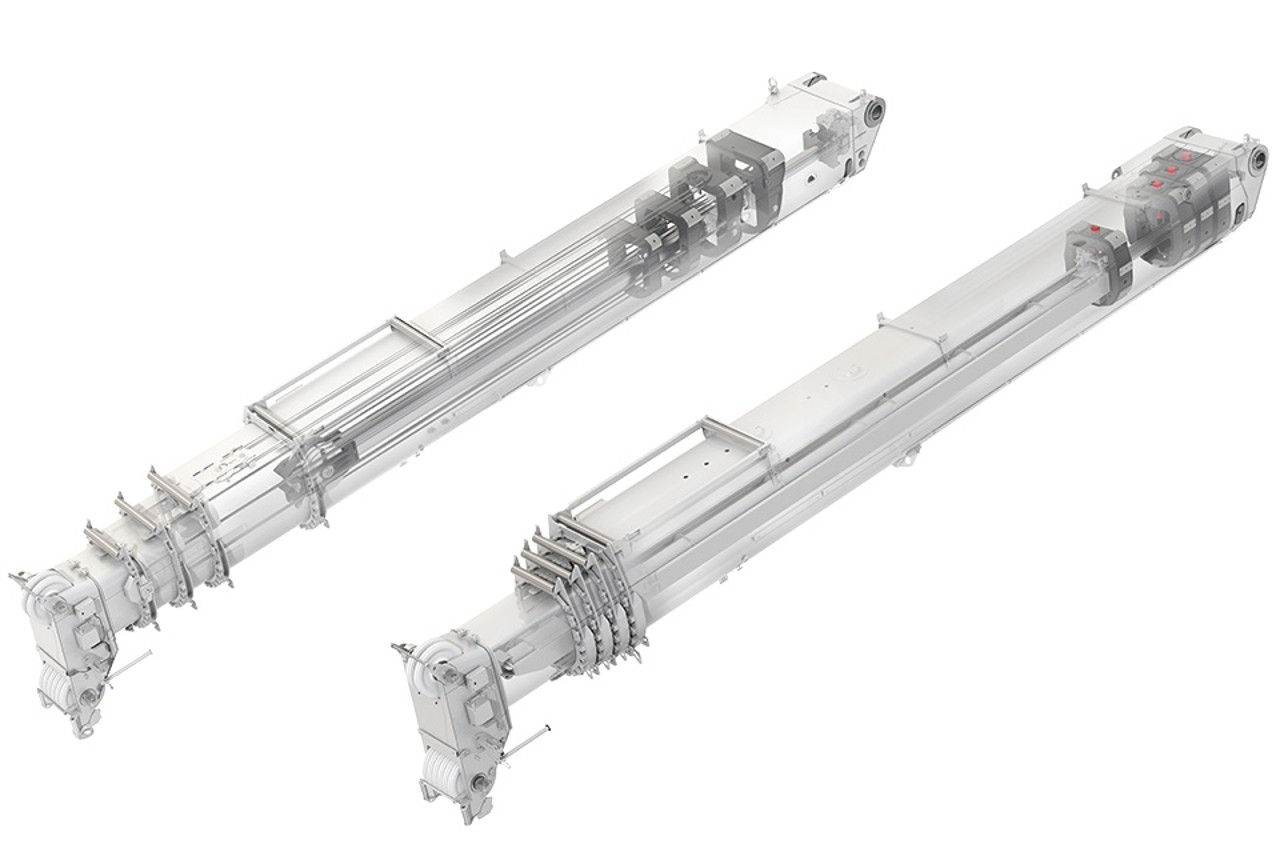

Telescoping technology

Our LRT 1090-2.1 features a fast telescoping due to the proven rope pulling technology. The two stage hydraulic cylinder comes with a rope extending mechanism.

The LRT 1100-2.1 has a longer telescopic boom with the Telematik telescoping system on which the various telescoping sections can be extended independently with a single cylinder and then pinned to the telescopic section above.

And we have preprogrammed it in a way to be even more easy to handle: You can select between two telescoping paths, strong or long.

Our products for your lifting tasks:

Max. load capacity - 90 t

90 t

Telescopic boom - 47 m

47 m

Max. hoist height - 66 m

66 m

Max. radius - 50 m

50 m

Number of axles - 2

2

Max. load capacity - 100 t

100 t

Telescopic boom - 50 m

50 m

Max. hoist height - 69 m

69 m

Max. radius - 54 m

54 m

Number of axles - 2

2

Max. load capacity - 130 t

130 t

Telescopic boom - 60 m

60 m

Max. hoist height - 85 m

85 m

Max. radius - 66 m

66 m

Number of axles - 2

2

The safest on the market.

UCR looked at our competition and decided Liebherr had the safest rough terrain crane on the market.

Joseph Mirabile, General Manager, M-L Holdings Co., UCR’s parent company

Clearly a winner in my books.

For the North American market I think the combination of the Cummins engine and the drive train is the best – also for service, parts availability and reliability in the long term. I think Liebherr really got it right on these RT cranes. That’s why I have to say the LRT is clearly a winner in my books.

Reagan LaPrairie, Director & VP Operations LaPrairie Cranes, Canada

Easy operation and tremendous service.

We're delighted by the opportunity to purchase rough-terrain cranes from Liebherr because – in comparison to other manufacturers – they provide a rapid spare parts supply along with tremendous customer service.

Another reason to opt for the LRT was the consistently easy operation of all Liebherr- mobile cranes, allowing the crane driver to get used to the different vehicles very quickly.

Matthias Wasel, Managing Director, Wasel GmbH, Schwerlastlogistik

The safe choice: Rough terrain cranes from Liebherr

Cranes from the market leader

Supplying the world crane market out of Ehingen since 1969, Liebherr is today the leading manufacturer of all terrain cranes. With the biggest product portfolio of 40 different cranes on wheels or on crawler tracks, we are renowned for our top technical level and innovative crane concepts.

Setting standards in the industry, we are responsible for designing and building a whole host of new technical ideas – just like the rough terrain cranes, the latest distribution to our product portfolio.

Worldclass service from the manufacturer

Liebherr cranes are reliable. When you need service for our products, you can rely on our global service network of more than 80 own sites in 35 countries. That network is backed by 70 years of history dating to 1949.

More than 95 percent of spare parts are available within 24 hours. This means more uptime for your crane and making your job a lot easier.