Group

GroupNews | 09/04/2024

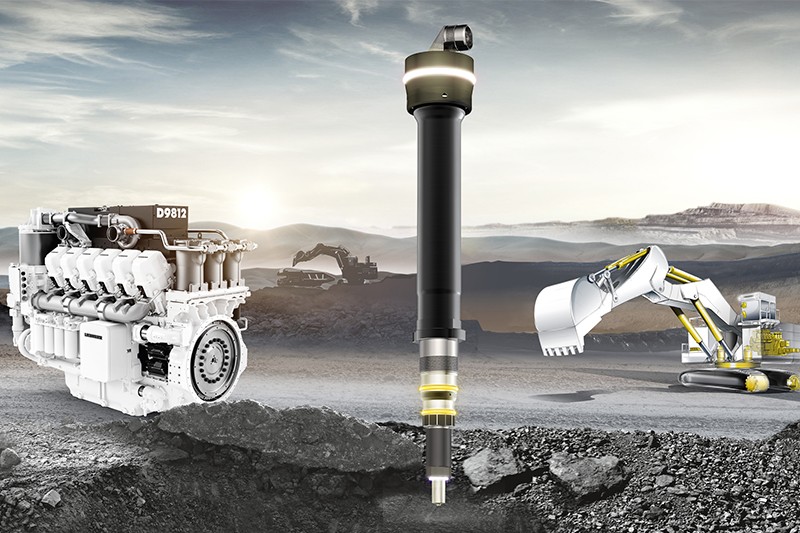

Liebherr's LI3 injector: exceptional performance in validation testing

The success story of Liebherr injectors continues: Following an exceptionally high runtime of 20,000 hours in field testing, the LI3 common-rail injector also passes subsequent validation tests. Once again, the results underscore the outstanding performance of this component.

The injectors of the LI3 product platform completed impressive 20,000 hours in a field endurance test without any difficulties. This corresponds to an increase of 25 per cent as compared to the expected service life of 15,000 hours. Even after the immense endurance, the injectors enable reliable engine operation without any loss in performance. This is also confirmed by extensive validation tests conducted subsequently to the field testing in Liebherr own test centres.

The results prove a significant progress for engine manufacturers and their customers. The use of the LI3 injector offers notable benefits including longer maintenance intervals thanks to the robust components and materials, which lead to lower maintenance costs. Less wear with an above-average service life also ensures stable engine operation and reduces the likelihood of damage or warranty claims.

Under the microscope: stable injection rates and robust components

The tests show that even after running for over 20,000 hours, the injectors deliver remarkable volume stability. Despite minor changes in the rate plateau, as well as the opening and closing delay, the injection rates remain in 96% of the test points within the standard limits. This guarantees consistent engine performance combined with impressive reliability and durability of Liebherr technology under tough conditions.

A detailed analysis of the injector components reveals that wear meets expectations and does not affect the functionality of the injectors. ʹIn our tests, we paid particular attention to the wear of the nozzle needleʹ, explains Georg Huber, a leading validation engineer at Liebherr-Components Deggendorf GmbH (Germany). ʹDuring opening and closing, the needle repeatedly contacts the seat area with high force, like a hammer striking the same spot over and over again. Eventually, both the hammer and the counterpart wear out. However, our needle is coated with a highly robust DLC layer, which reduces wear not only on the needle, but also on the nozzle.ʹ

Another crucial aspect of the tests was the examination of cavitation inside the nozzle - around the blind hole and the spray holes. Compared to reference injectors, the Liebherr injectors exhibit minimal cavitation effects in these areas. This test is of particular importance, as cavitation can cause considerable problems during engine operation. With relatively low cavitation effects, the injection rate, and thus the engine performance remains stable. Therefore, the risk of nozzle rupture and the associated engine damage is considered low. Lastly, such effects also influence the shape of the fuel spray in the combustion chamber. If the latter is impaired by wear of the spray holes, it directly affects the emission output of the engine. Hence, the minimal cavitation of Liebherr injectors ensure stable emission values.

More efficient operation of large engines up to 500 kW/cyl

The convincing validation results confirm the quality and performance of Liebherr injectors. The LI3 thereby enhances the efficiency and reliability of large engines in the power range of up to 500 kW/cyl. Looking ahead, both engine manufacturers and end users can benefit from the advantages of stable and durable injection technology, resulting in lower operating costs and increased operational reliability.