Exceptional growth and high investments

In the fifth decade since it was founded, the Group grows extremely dynamically: extensive investments as well as new organizational structures reinforce the competitiveness of the company on an international scale.

Assembling printed circuit boards in Lindau (Germany)

2001 Pooling of electronics expertise

Liebherr-Elektronik GmbH in Lindau (Germany) starts operations. A modern competence center with state of the art technology dedicated to manufacture electronic assemblies and systems for construction machinery and mining equipment, maritime cranes, aircraft and rail cars among others.

About a third of the personnel are employed in the research and development department. They have detailed knowledge of electronic hardware design and specialize in the area of aviation and industrial applications.

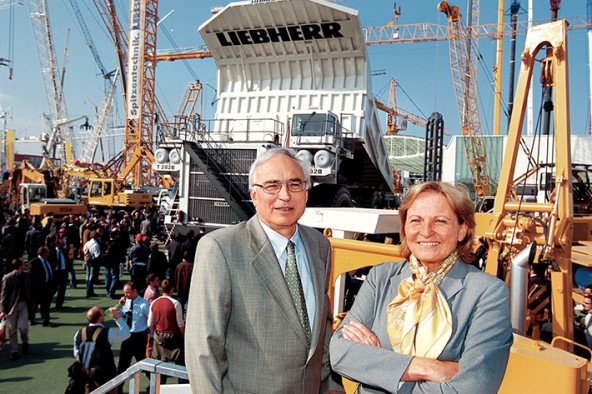

Isolde Liebherr and Willi Liebherr in 2004 at the Bauma trade fair in Munich

2002 Restructuring according to product areas

The previously country-based organization of the Group is replaced by a product-area-based structure: an important step to consolidate sales and technology resources in a stronger way and deploy them with greater effectiveness.

As a holding company, Liebherr-International AG in Bulle (Switzerland) decides centrally on fundamental matters regarding corporate policy, development and product policy as well as finance and investment policy. The product divisions operate as autonomous business units. This ensures that each of the product areas can respond in a tailored and target-orientated manner. Additionally, new technologies can be incorporated in products compatible with the market.

2003-08 Exceptionally dynamic growth

In 2003 to 2008, the Group grows remarkably well. The consolidated overall turnover during this period is more than double and reaches 8.4 billion euros.

At the same time, Liebherr invests almost 2.8 billion euros in extending existing sites and constructing many new production sites.

The sales and service organization is also significantly expanded. Around the world, almost 12,000 new jobs are created within the Group during these six years.

Parasols with crane technology in Saudi Arabia

2008-09 Large parasols for Medina

Liebherr-Werk Ehingen GmbH is commissioned to produce large parasols for a pilgrimage site in Medina, Saudi Arabia.

During development of the 15m high umbrellas the company is able to draw on its expertise for crane technology. To ensure that the parasol can provide shade, a hydraulic cylinder has to unfold a roof and raise it five meters above the ground. Each of the 250 screens produced offers about 800 pilgrims protection from the sun.

Container loading bridges from Liebherr on Southampton harbor (Great Britain)

2009 Solid even in unsettled times

As an international Group, Liebherr also experiences the consequences of global depression and financial crises. Despite taking a drop in profits, the number of employees remains steady and central investment measures are continued. As was the case during previous slumps in the market economy, the product variety and presence in different markets are able to stabilize the organization as a whole. Just one year later and the Group is able to record a positive turnover of almost ten percent.