Gear technology and automation systems

Gear technology and automation systemsPress releases | 04/07/2025

Bauma 2025: Liebherr demonstrates the future of construction and mining with ‘Hands on the future’

- In focus: pioneering solutions for the construction site and mining industry of tomorrow

- Key topics: products, digitalisation, responsibility, partnership and customer focus

- Maximum presence: over 100 exhibits, components, theme pavilions and an InnovationLab over an exhibition area of more than 15,000 m² as well as an outdoor test & drive area for customers

At Bauma 2025 in Munich, Liebherr is presenting itself as a pioneer and technology leader in many industries. Guided by the motto ‘Hands on the future’, the Group is presenting future-oriented exhibits, technological innovations and practical solution concepts for increased efficiency, safety and environmental compatibility – for the construction and mining industry of the future. Not only can visitors look forward to around 100 machine exhibits, components and technologies, but also a varied programme with live shows on Liebherr Square, an InnovationLab, theme pavilions and a career lounge.

The future starts now. And Liebherr is doing its bit to start shaping it today – for its customers, for the environment and for current and potential employees. The Group’s motto for Bauma 2025 – ‘Hands on the future’ – captures this doer mindset in a nutshell. At the same time, it represents the collaborative approach that has characterised Liebherr’s actions for more than 75 years. Hand in hand with its customers, Liebherr develops products and solutions that have been tailored to the needs of the construction industry and have a high utility value in practical application.

At Bauma 2025, Liebherr is demonstrating what ‘Hands on the future’ means in practice: on an exhibition area spanning over 15,000 m² – that’s bigger than the size of two football pitches – the Group is presenting more than 100 future-focused exhibits from the product segments of earthmoving, material handling technology, mining, mobile and crawler cranes, tower cranes, deep foundation, concrete technology and components. Beyond these segments, the Group’s exhibition appearance is also characterised by the topic areas of products, digitalisation, responsibility, partnership and customer focus. It is also exhibiting innovations that set new benchmarks in these topic areas. ‘We are actively shaping the future of the construction site by creating solutions that offer sustainable added value for our customers,’ said Stephen Albrecht, Managing Director Technology and Digitalisation of Liebherr-International AG, speaking about the Group’s exhibition appearance at Bauma 2025.

Showtime: experience future technologies live in action

Liebherr is presenting many innovative solutions for the future of construction and mining live in action at demo shows. For example, the Group is demonstrating future-oriented heavy-weights in action outdoors on Liebherr Square: the battery-electric, autonomous T 264 mining truck, with a payload of 240 tonnes, combines top performance with zero emission operation. Its battery system, developed by the Australian mining customer Fortescue, which specialises in green technologies, enables both static charging via a robotic charging arm and dynamic charging. For dynamic charging, the mining truck connects to the Liebherr lateral power rail while travelling and is automatically supplied with energy. This means the machine can work without interruption, significantly increasing the efficiency of the mining operation. The electric R 9400 E mining excavator also works with zero local emissions. This 350-tonne machine, whose impressive shovelling movements are being demonstrated at the trade show, can be connected directly to the mains via a cable up to 300 metres long or to a battery energy storage system. The electricity at the trade show, required for the excavator movements amongst other things, is produced exclusively using regenerative sources.

In the neighbouring showcase for the earthmoving product segment, driverless machines are a hot topic. For the first time, the L 550 XPower wheel loader is being presented as an autonomous model. The ‘Autonomous Job Planner’ web application can be used to pre-programme the work steps that will be executed autonomously by the machine. In addition, the driverless PR 726 crawler dozer and driverless R 926 crawler excavator show what they are made of in a live demonstration. Both machines can be operated from the control desk in the Liebherr InnovationLab using the ‘Liebherr Remote Control’ technology.

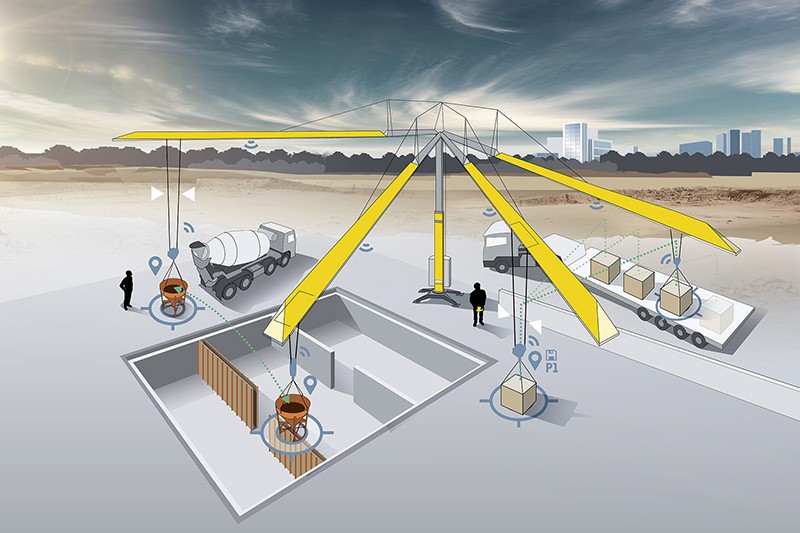

The tower cranes segment, for its part, is showcasing five new assistance systems for tower cranes, including the so-called ‘Positioning Pilot’. With this technology, a fast-erecting crane can plot and save routes and repeat them semi-automatically. The machine automatically approaches stored points again, without any support from the crane operator. This innovation has been nominated for the Bauma innovation award in the ‘Machine technology’ category.

Premieres: innovations presented for the first time

At Bauma 2025, Liebherr is presenting numerous world, European and trade show premieres. For example, the earthmoving product segment is celebrating a world premiere with the T 38-7s – the new Generation 6 telescopic handler. For this new version of the ‘S’ telescopic handler in the lower performance class of up to 4.2 tonnes, the load capacities have been increased by up to nine per cent. Newly available assistance systems extend the possible applications and make machine operation easier and safer. With the new T 48-8s telescopic handler, Liebherr is marking its entry into the 8-metre class, extending its product programme in the industry segment.

Also in the earthmoving segment, there are two new battery-electric excavators: the battery-electric R 920 G8-E is a world innovation and strong example of an alternative drive. It has the same performance level as a crawler excavator with a combustion engine, but sets itself apart thanks to its low noise development and zero emissions. This model is ideal for urban construction sites and for tasks in halls or tunnels, where low noise and emissions values are key. The battery-electric A 918 E wheeled excavator also scores highly with its low-noise and low-vibration operation. The electric drive significantly reduces carbon emissions compared to a conventional diesel excavator, while at the same time reducing energy consumption and thus energy costs. The reduced maintenance effort also contributes to the reduction of operating costs. The HS 8100.2 Dual Power cable excavator with zero local emissions, which enables both purely electric and a mixture of conventional and electric operation, is also celebrating its premiere.

As far as alternative drives are concerned, Liebherr is presenting yet another exhibition premiere in the form of the L 566 H – the first large wheel loader with a hydrogen engine. In cooperation with STRABAG, the machine is currently being tested in the Kanzelsteinbruch quarry in Gratkorn (Austria), including refuelling with green hydrogen via an on-site filling station. Following many years of research, H2 drives have proven themselves to be the best technology for heavy vehicles. Prospective customers can view the innovative large wheel loader at the Liebherr booth. In addition to wheel loaders from other series, Liebherr is also exhibiting the battery-electric L 507 E wheel loader, as another example of alternative drives.

And the Liebherr mobile and crawler cranes are also celebrating a world premiere: the LTM 1150-5.4 E mobile crane, with its 111 kW electric motor, delivers almost the same performance as a six-cylinder combustion engine and enables unlimited crane operation. The innovative drive concept is based on the proven technology of the LTC 1050-3.1 E, but has been decisively boosted with an integrated battery pack. The crane can work self-sufficiently for up to four hours and only requires a low connected load for mains operation, as the battery acts as an efficient buffer.

For the first time, Liebherr is also presenting the LR 1300.2 SX unplugged as the latest member of the unplugged crawler crane series. This 300-tonne crawler crane with battery-electric drive was designed specifically for high-rise construction and deep foundation. At Liebherr, machines that can run on batteries, without a cable connection, are called unplugged. Whether plugged in or unplugged, the performance and range of applications remain unchanged.

Moving on to the Liebherr tower cranes, the latest generation of 43 K, 61 K and 91 K fast-erecting cranes are being exhibited for the first time at Bauma 2025. They are equipped with intelligent assistance systems: the ‘Vertical Line Finder’ ensures that the load hook is always optimally aligned above the load centre. The ‘Guided Hook’ enables simple, direct operation of the load hook by a person on the ground. Both assistance systems increase the convenience of crane operation and improve safety and efficiency on the construction site.

The concrete technology product segment is presenting the Mobilmix 4.0 concrete mixing plant for the first time. The largest variant of this machine, with a 4 m³ twin-shaft mixer, will celebrate its world premiere at Bauma 2025. The modular construction system gives users more freedom in terms of the plant configuration. Other advantages include reduced delivery times, faster assembly and high availability of parts. In addition, improvements to the drives reduce power consumption by up to 30 per cent, while increased weighing precision ensures cement savings of up to eight kilograms per cubic metre of concrete.

Even beyond construction machines, cranes and mining, Liebherr is making its presence felt at Bauma 2025: in the atrium of the main building, the aerospace product segment is exhibiting the wing of a Boeing aircraft. And the household appliances segment is offering exciting insights into its groundbreaking ‘BluRoX’ insulation technology in the InnovationLab at the trade show.

Efficient, safe, environmentally compatible: digitalisation as a key factor

Liebherr is focusing on the digitalisation of its construction machines, because the future belongs to digitalised construction sites – they are more efficient, environmentally friendly and safer than their analogue predecessors. The Group is focusing on intelligent assistance systems, autonomous functions and networking.

With the help of advanced digital assistance systems, construction machines can independently scan their surroundings, recognise obstacles and even assess weather conditions, thanks to cameras and sensors. This ensures a significantly higher level of safety on construction sites.

In terms of autonomy, Liebherr is working on products that can perform tasks either fully or semi-autonomously, such as digging, transporting or compacting materials. The special thing about these machines is that they can do more than just travel along completely driverless, pre-defined routes and perform monotonous work processes. Autonomous machines with integrated AI are capable of learning. This can be seen in the fact that the machines are continuously optimising their own performance and, for example, can independently define the ideal route or optimal actuating angle into the bulk mass in every situation – always with the aim of maximising the efficiency of the machine operation while minimising energy consumption and wear.

Networking is another important aspect of digitalisation. Through integration in a shared network, machines can communicate with each other and coordinate their work processes. This results in a better use of resources and minimises downtimes. The Liebherr Group has set a milestone with Liebherr Connect, which uses intelligent machine networking to provide access to digital solutions and services, as well as extensive machine data and process data. When using fleet and asset management systems, Liebherr Connect forms an essential basis for all kinds of condition monitoring for components or machines.

Another example is the ‘Liebherr Remote Control (LiReCon)’ concept for machines. With this, Liebherr is going one step further: this solution enables machines to be controlled from a long distance away – entirely without an driver. The new thing is that several machines can be controlled simultaneously from one and the same external control stand, including machines from different product segments. At Bauma 2025, Liebherr will be demonstrating LiReCon in action with a crawler dozer, a crawler excavator and a tower crane.

Future generations at a glance: Liebherr brings responsibility to life

As a globally active family-run company, Liebherr bears responsibility for society and the environment. It aims to act responsibly and in a future-oriented manner, and to always keep the well-being of the next generation and beyond in mind. Many Liebherr products and technologies play an important role in the post-fossil transformation. With its products, for example, Liebherr is centrally involved in the energy revolution. From mobile cranes for the construction of wind power plants to components for wind turbines, the Group offers solutions that drive forward the efficiency and performance of wind energy. Take, for example, the LG 1800-1.0 powerhouse, which is showing what it’s made of at Bauma 2025: this power crane is the biggest exhibit at the Liebherr booth and combines the mobility of a mobile crane with the lifting capacity of a crawler crane. With an axle load of just ten tonnes, it is approved for use on public roads worldwide and is particularly well-suited to the construction of wind farms: from turbine to turbine with a three-metre wide chassis.

In addition to taking responsibility for its customers and their safety when they are working with Liebherr machines, Liebherr also takes responsibility for the impact of its products on the climate and environment. Its top priority is to keep reducing the ecological footprint of its products throughout their entire life cycle, from development to disposal. The use of the machines that cause the most emissions is currently the main focus here.

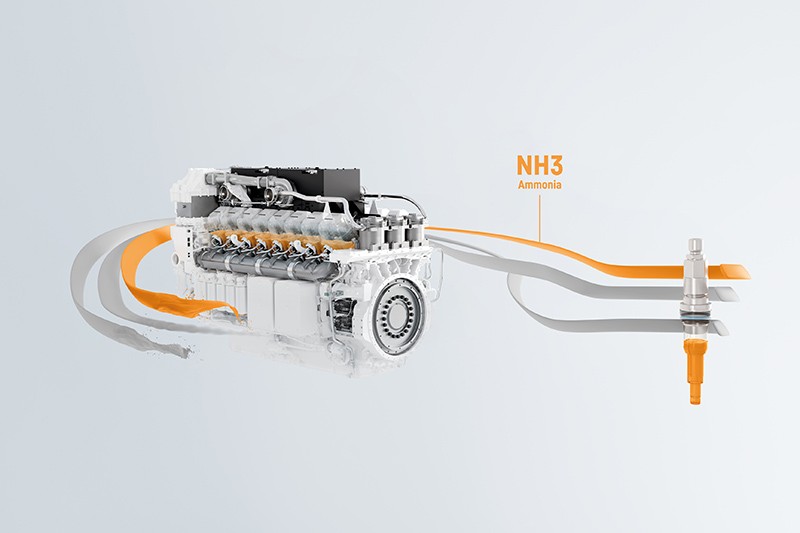

Liebherr can make an impact here through its work on drive technologies for construction machines, cranes and mining equipment. Its approach is deliberately open-minded, because the optimal drive differs according to the type of machine, the project and the work environment in question. The technology portfolio with which Liebherr works is correspondingly wide. From battery-electric, grid-connected, hydrogen-operated, HVO-compatible machines to the first mock-up concept of an ammoniac motor: Liebherr is working on the solutions that are most suited to the respective customer requirements. And it is thinking ahead too: coupled with electric machinery, the new version of the Liduro Power Port (LPO) mobile energy storage system from series 100 and the prototype of a stationary LPO 600 energy storage system enable a zero local emissions energy supply for construction sites. The LPO 600 mobile charging station has a gross energy content of 564 kWh and can provide sufficient energy for large machines or fleets, even in terrains without the relevant infrastructure.

Creating added value with practical relevance: partnership and customer focus at Liebherr

Facing the future, hand in hand with its customers: Liebherr is a stable, reliable partner, providing support for its customers. Individual consulting and support services are just as important to the Group as long-standing partnerships in which Liebherr assists its customers as a development partner, developing customised solutions in collaboration with them. For example, Liebherr and the Australian mining and technology Group Fortescue are jointly developing mining machines for emissions-free and autonomous mining work by 2030. Fortescue’s contribution to this cooperation is a battery-electric system and its expertise in autonomy. 475 Liebherr machines, the largest order in the Group’s history, will be sent to Fortescue’s mines in Australia as part of this partnership. The industry has long been dependent on fossil fuels – but now this partnership is paving the way for a new era of eco-friendly and more efficient mining. All three machine models that are covered by this cooperation can be seen live at Bauma 2025.

Another example is the partnership with STRABAG: in addition to the H2-operated wheel loaders, which can be seen in action at Bauma 2025, the partners are collaborating with the filling station manufacturer ‘Maximator Hydrogen’ to find solutions for a mobile hydrogen filling station that can supply H2-operated construction machines with this zero-emissions fuel on-site. This is an important project, because Liebherr not only wants to provide its customers with the machines, but also, where possible, to provide or recommend the corresponding infrastructure.

Recruiting: talent acquisition at Bauma 2025

‘Hands on the future’ – many hands have been hard at work every day to ensure that all products, technologies and solutions can be seen at the trade show. With their expertise and enthusiasm for the products and technologies, as well as their own ideas, over 50,000 employees worldwide are involved in creating something amazing and ensuring that Liebherr is always able to set new standards in a variety of industries.

At Bauma 2025, employees come together not only from the most diverse product segments, but from all over the world. Across the week of the trade show, around 2,000 employees from almost 50 countries will be on-site. At the trade show, Liebherr, with its own HR area – the career lounge at the main exhibition booth – will be presenting itself as an employer, offering fascinating insights into what it’s like to work in the Group, to attract new talent for the future. Prospective employees can also go to the ‘Think big – Training at Liebherr’ stand in the international congress centre in Munich, to find out about the variety of job offerings within the Group, gaining fascinating insights into the daily work of Liebherr employees first-hand and speaking to recruiters.