LTM 1150-5.3

Mobile crane

LTM 1150-5.3 - The jewel in your fleet.

With a maximum lifting capacity of 150 tonnes (175 USt) and a long telescopic boom, the LTM 1150-5.3 is the perfect addition to Liebherr’s crane range below the LTM 1160-5.2. With an axle load of twelve tonnes (26,450 lb), the crane can carry nine tonnes (19,800 lb) of ballast on public roads. This ballast enables it to complete lots of jobs without requiring an additional vehicle to transport the ballast. Its powerful telescopic boom can be extended with lots of add-on jibs. These are compatible with many of our cranes with lifting capacities between 100 and 180 tonnes (220,500 lb and 396,830 lb). We have continued our single-engine strategy on this crane with a mechanical drive unit for the superstructure. The weight reduction created by the elimination of the superstructure engine is used to deliver a longer boom and more lifting capacity.

Max. load capacity - 150 t

150 t

Telescopic boom - 66 m

66 m

Max. hoist height - 92 m

92 m

Max. radius - 72 m

72 m

Number of axles - 5

5

What's inside

Lots on board:

Economical design:

Makes a great deal possible:

Off-road assistance:

Efficient:

Hook block can be ballasted:

Photo gallery

Technical data

| Max. load capacity | 150 t |

| at radius | 3.00 m |

| Telescopic boom from | 12.30 m |

| Telescopic boom up to | 66.00 m |

| Lattice jib from | 2.90 m |

| Lattice jib up to | 26.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 400 kW |

| Number of axles | 5 |

| Drive/Steering standard | 10 x 6 x 10 |

| Drive/Steering option | 10 x 8 x 10 |

| Driving speed | 85.00 km/h |

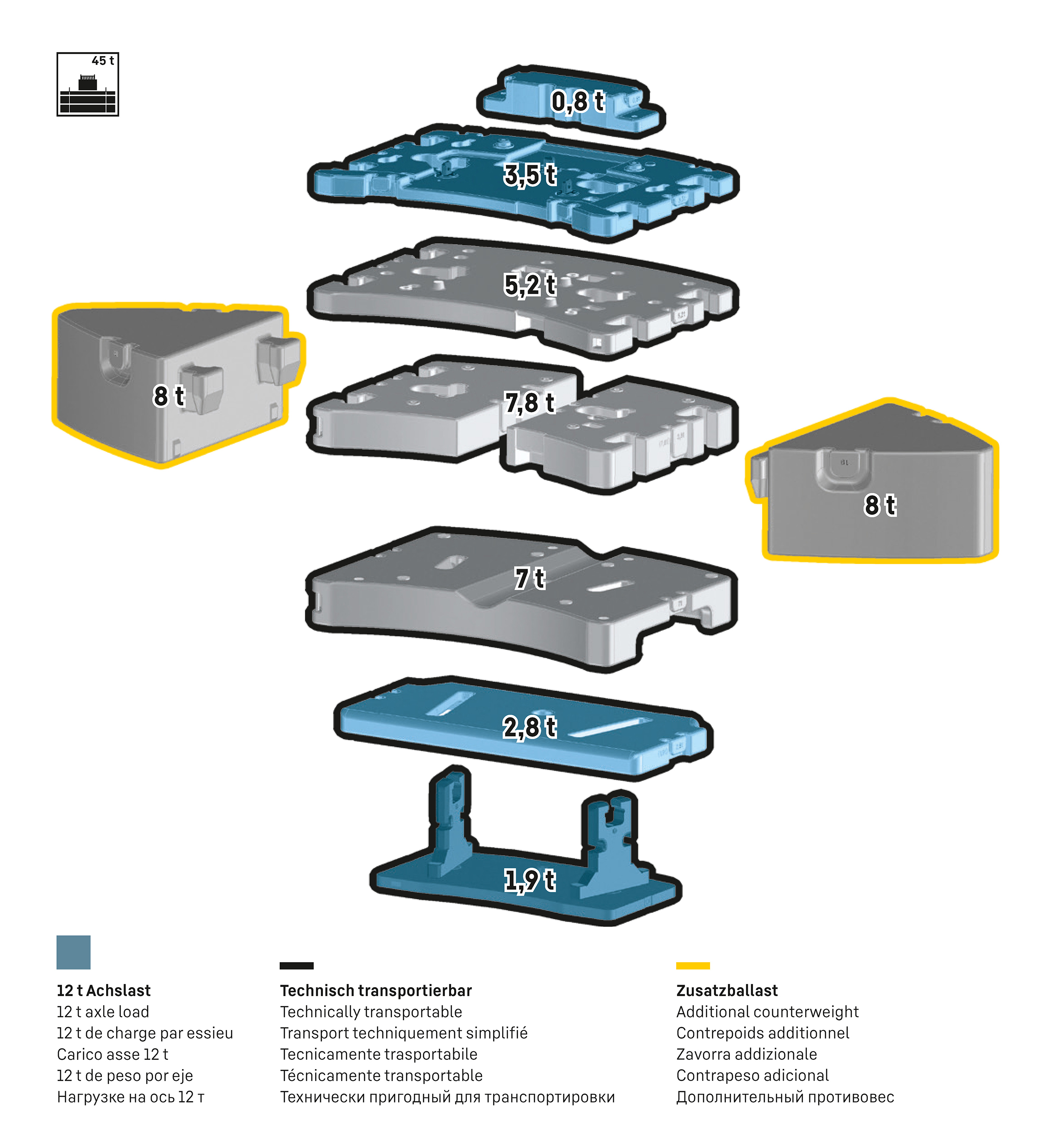

| Total ballast | 45.00 t |

Downloads

Videos

LTM 1150-5.3 - The jewel in your fleet

LTM 1150-5.3 - The new One in permanent use

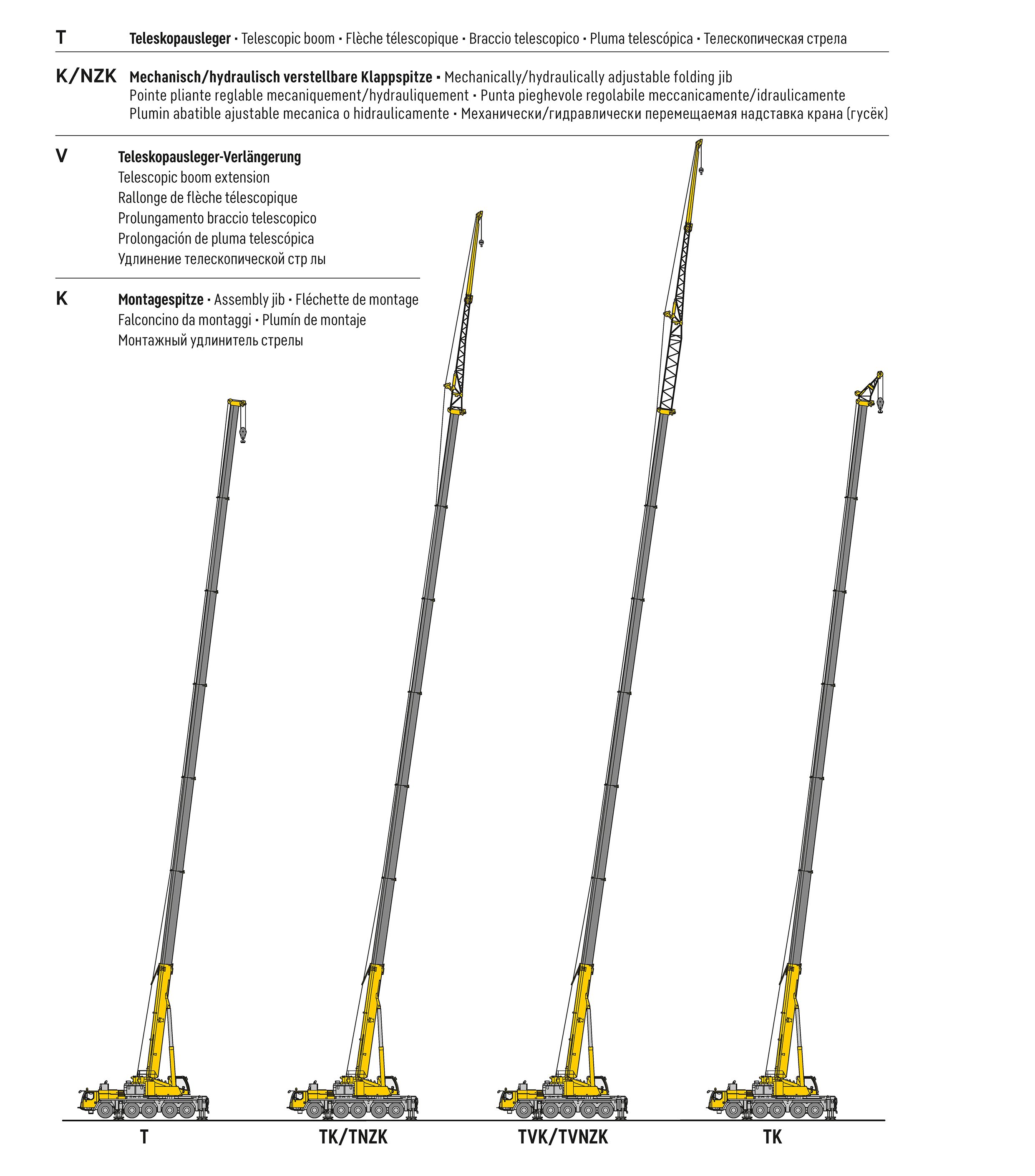

Boom/jib combinations

Boom/jib combinations

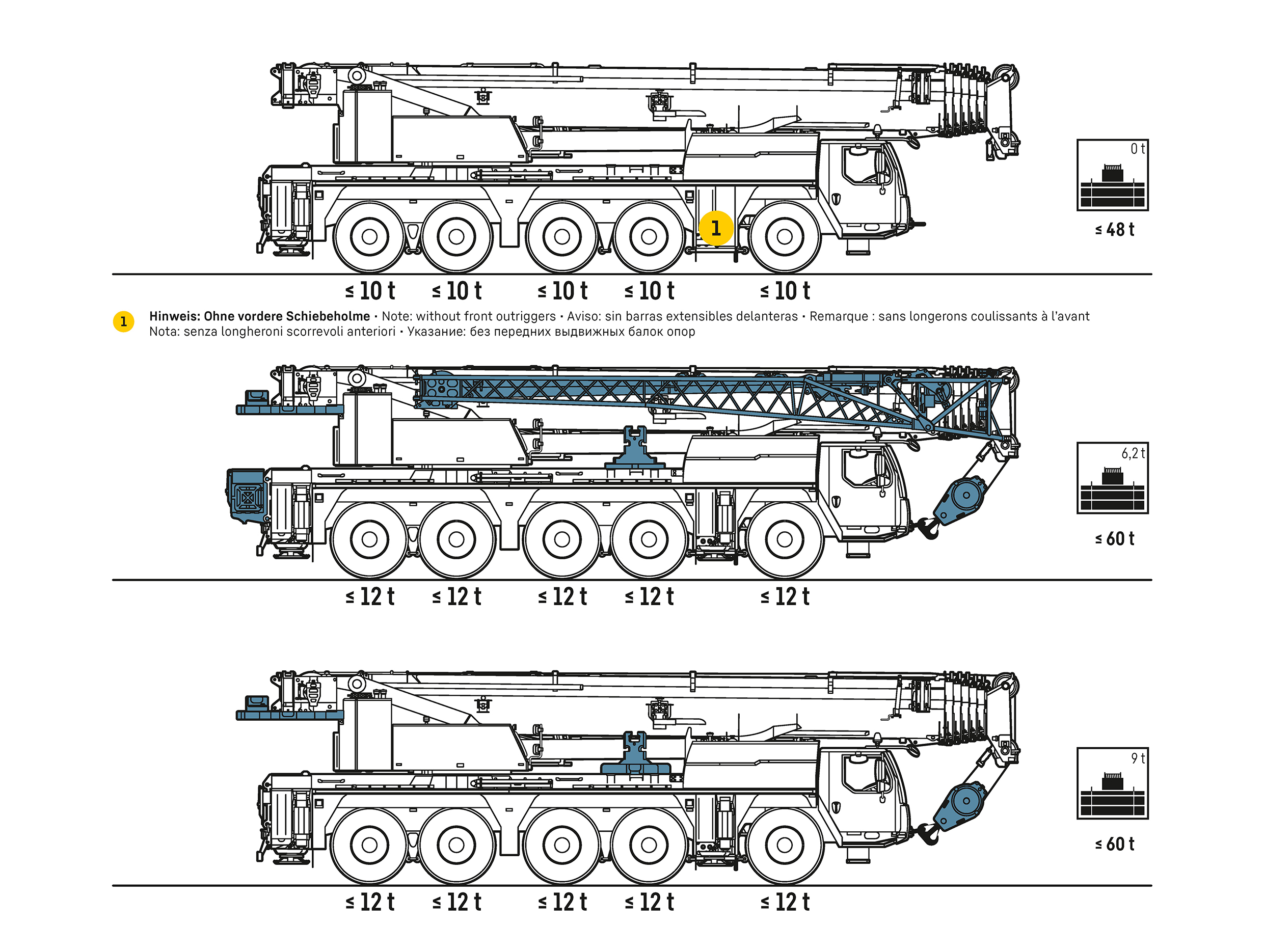

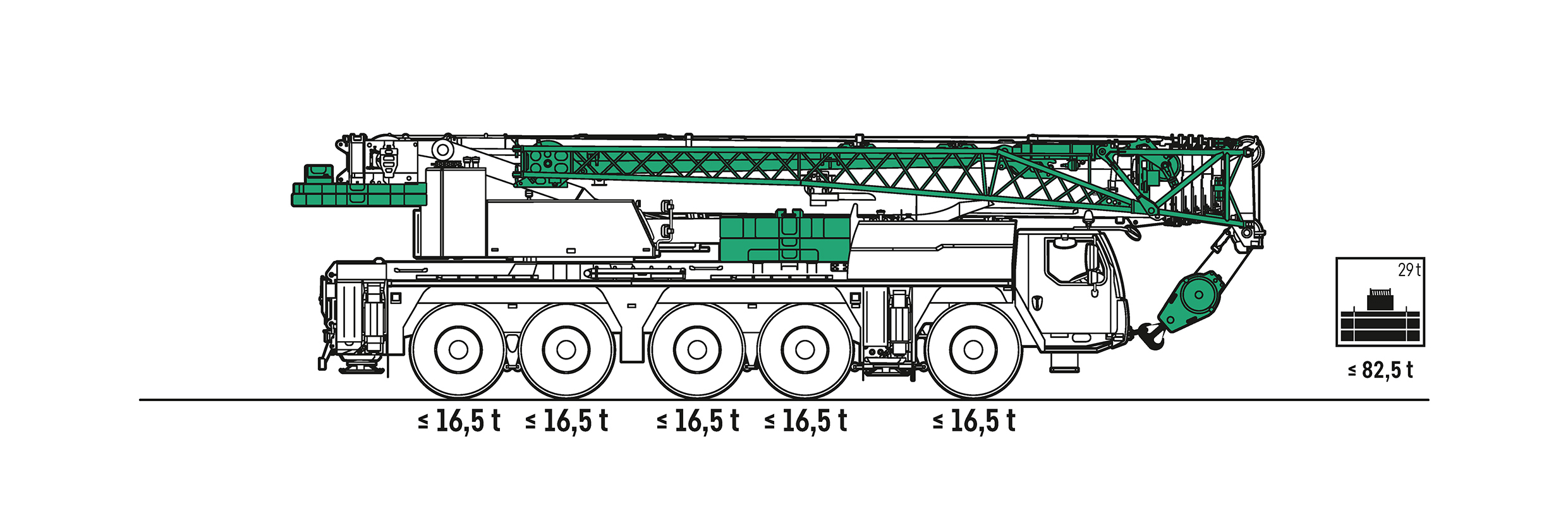

Driving conditions

On-road driving

Jobsite driving

Ballast systems

Counterweight

Technology

ECOmode

ECOdrive

Single-engine concept

Hillstart-Aid

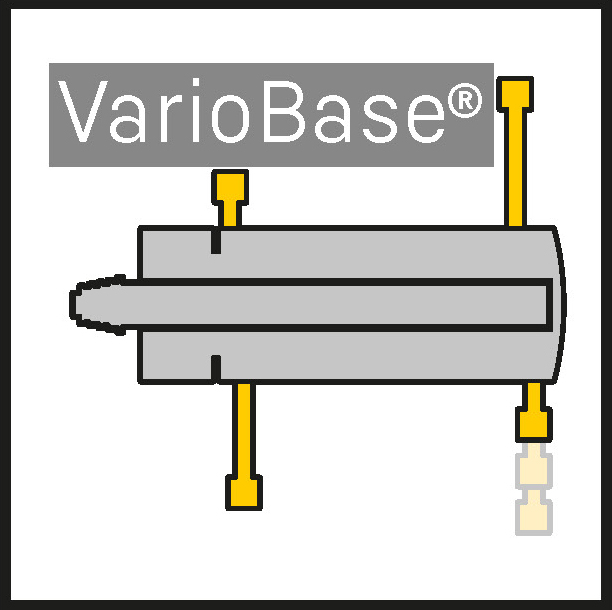

VarioBase®

AutoBallast

WindSpeed load charts