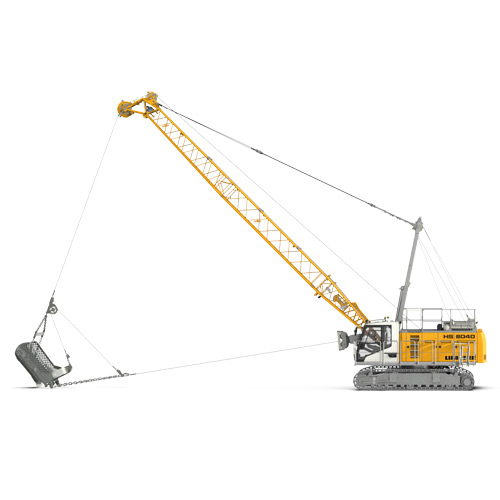

HS 8040.1

Duty cycle crawler crane

With a maximum lifting capacity of 40 tonnes, the HS 8040.1 is the smallest in the proven HS series. However, when it comes to compactness, it comes up trumps. A transport weight of less than 40 tonnes makes it the perfect choice if the machine has to be transferred frequently between job sites.

Max. lifting capacity - 40 t

40 t

Engine power - 230 kW

230 kW

Max. winch line pull - 2 x 120 kN

2 x 120 kN

Max. main boom - 41.00 m

41.00 m

Availability -