Digitalization with sense of proportion

The digital transformation, with its opportunities and risks, is a ubiquitous topic which is also being intensively addressed by Liebherr-Verzahntechnik GmbH. Michael Messer and Peter Wiedemann, General Managers for Production and Sales, view digitalization as a strategic challenge which must be implemented with sense of proportion and with a focus on customer benefit.

How is Liebherr-Verzahntechnik GmbH approaching the topic of digitalization, and where do you see the greatest potential for the company?

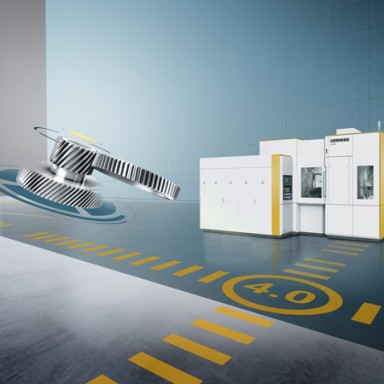

Michael Messer: We want to place the topic in the areas where we can best promote it. The questions we are asking ourselves in relation to this are: How do we integrate our products into digital worlds? Which virtual solutions can we implement in service and communications? And to what extent are we promoting the idea of Industry 4.0 in our own company landscapes as well? One thing, at any rate, is clear: Digitalization is not an end in itself and must fit in with our philosophy. The focus is on customer benefit.

Peter Wiedemann: I see a lot of potential in the area of research and development, and in after-sales service. Here, we are intensively addressing topics such as predictive maintenance and predictive service. We are tackling them purposefully and with dynamic ambition, but we are also remaining realistic, because we are reliant on data which have to be gathered in a cooperative dialog with the customer.

Talking of data protection, how do you get customers on board with this and gain their trust?

Peter Wiedemann: Data protection is a sensitive topic. In order to benefit from digital solutions, you have to let the other party view their own data. Customer acceptance of this has grown considerably in the last few months. A good example of this are remote services: Customers have experienced benefits from the fast and uncomplicated processes. We are able to score here because we are perceived as a reliable partner, and customers trust us – particularly for more complex topics which require a lot of expertise and experience.

Michael Messer: We supply highly specialized solutions for our customers’ individual requirements. That’s why we are always reliant on intensive dialog. This goes far beyond what you can offer with a standardized app, for example. Formats such as our Live Online Training or live-streamed machine pre-acceptances combine the virtual and real world and are far more able to serve this purpose.

Liebherr Performance Days have taken place in Europe, America and Asia under the motto “Real life meets virtual Tech Arena”. How do you assess the success of the virtual trade fairs?

Peter Wiedemann: In virtual exhibition rooms and video talks with chats and workshops, visitors were able to experience the technologies of gear technology and automation virtually and to interact with us. This was very popular: We had a similar number of contacts to the EMO 2019, for example. Further events are planned. We aim to offer even more live and interactive formats to continue to improve our availability.

Michael Messer: An advantage of the virtual trade show is that we are not tied to show dates to introduce our new products and can therefore present our solutions to customers and interested parties when they appear.

Has digitalization also had an effect on communication?

Michael Messer: Definitely! We were very quick to react and efficient in organizing our digital structures. This meant that our availability, particularly in the area of service, was continuously guaranteed even during the pandemic. However, informal communication has suffered. The usual, important conversations between colleagues “in passing” have not yet arrived in the virtual space.

Peter Wiedemann: From a sales point of view, I can confirm that. Certainly, the use of virtual possibilities here can also, in the future, remove the need for some journeys which previously involved a considerable outlay of money and time. Despite this, employees, customers and business partners are longing for a meaningful combination of personal and virtual contact. It is also still extremely difficult to build new relationships and the trust needed for these using purely virtual media.

What are the future challenges of digitalization for Liebherr-Verzahntechnik GmbH?

Michael Messer: Developments so far confirm that we should carry on the path we have taken: solution-oriented and not influenced by buzzwords. Basically, Liebherr-Verzahntechnik GmbH has already been focusing on many topics of Industry 4.0 for a long time. Digital information about the machine status is not really new for us. We are continually monitoring the potential for further digital solutions in our portfolio. In doing so, we are not always the first to bring new hypes onto the market, but when we do take something up, we also implement it lastingly.

Peter Wiedemann: Digitalization helps us to focus, but also makes us more flexible. It is important to check carefully how to combine the best of both worlds in our business relationships: efficiency and personal interaction.