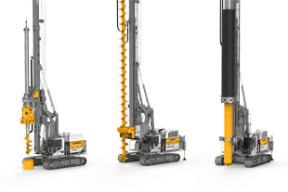

LB 30 unplugged

Drilling rig (LB series)

The LB 30 unplugged is a deep foundation machine with an alternative drive concept. During operation the drilling rig can be connected to a conventional electric supply or powered by battery without a cable, therefore “unplugged”. There are no restrictions in performance and application of the machine when compared to the conventional version with diesel engine.

Operating weight - 75.5 - 85.5 t

75.5 - 85.5 t

Max. torque - 297 kNm

297 kNm

Kelly drilling, max. drilling depth - 70.8 m

70.8 m

Kelly drilling, max. drilling diameter - 3,400 mm

3,400 mm