The Liebherr Christmas Bakery

Immerse yourself in Liebherr's fascinating Christmas world and see what surprises a dream world can have in store.

When dreams come true

Grandma Vroni's biscuit recipe: Classic cut-out butter biscuits

Ingredients:

- 400 g flour

- 250 g butter

- 1 egg yolk

- 120 g sugar

- 1 pinch of salt

- 1 packet vanilla sugar

- 1 shot glass of rum

- Grated zest of one lemon

Preparation:

1. Sift the flour. Make a well in the middle. Add the sugar, egg yolk, vanilla sugar, lemon zest, rum and salt and spread the butter in flakes on the flour.

2. Knead all the ingredients into a smooth dough and form a ball. Then wrap it in aluminium foil and leave to cool for 2 hours.

3. Preheat the oven to 180°C and line the baking tray with baking paper.

4. Roll out the dough on a floured work surface to a thickness of approx. 3 mm and cut out the biscuits.

5. Place the biscuits on the baking tray and decorate.

6. Bake the biscuits for 10 - 15 minutes until golden brown. Let them cool and enjoy.

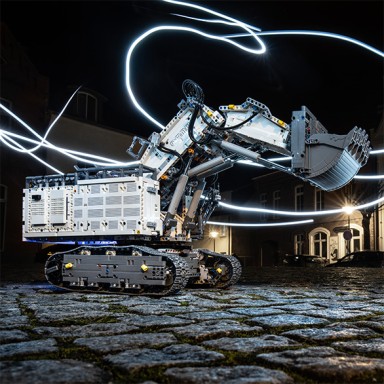

Every detail counts – Making-of stop motion film

The Liebherr Christmas bakery was mainly produced as a stop motion film – one of the most intricate ways of producing a film. There are more than 2,500 individual pictures, a few clever tricks, many helping hands and a lot of preparatory work behind 2 minutes of film. Because every detail counts and every wrong move sets things back by hours.

In principle, a stop motion film is easy to make: you take a picture of an object, then you move the object a little, take another picture and finally, you string together all the photos. The more pictures per take there are, the smaller are the movements.

The Liebherr Christmas bakery consists of 2,787 individual images, which are then played at a speed of 24 images per second. Before this can happen, though, such a production requires a lot of preparation. Every single scene is sketched out in advance so it is clear what exactly happens when and how, which camera angle is necessary and which props are needed. Because at the time of the actual shoot, every movement has to be done correctly. Nothing can be moved or rearranged unconsciously. The camera has to remain in position constantly as well and only records a precisely defined area. Besides 16 models from the Liebherr shop, about 40 other props were also used.