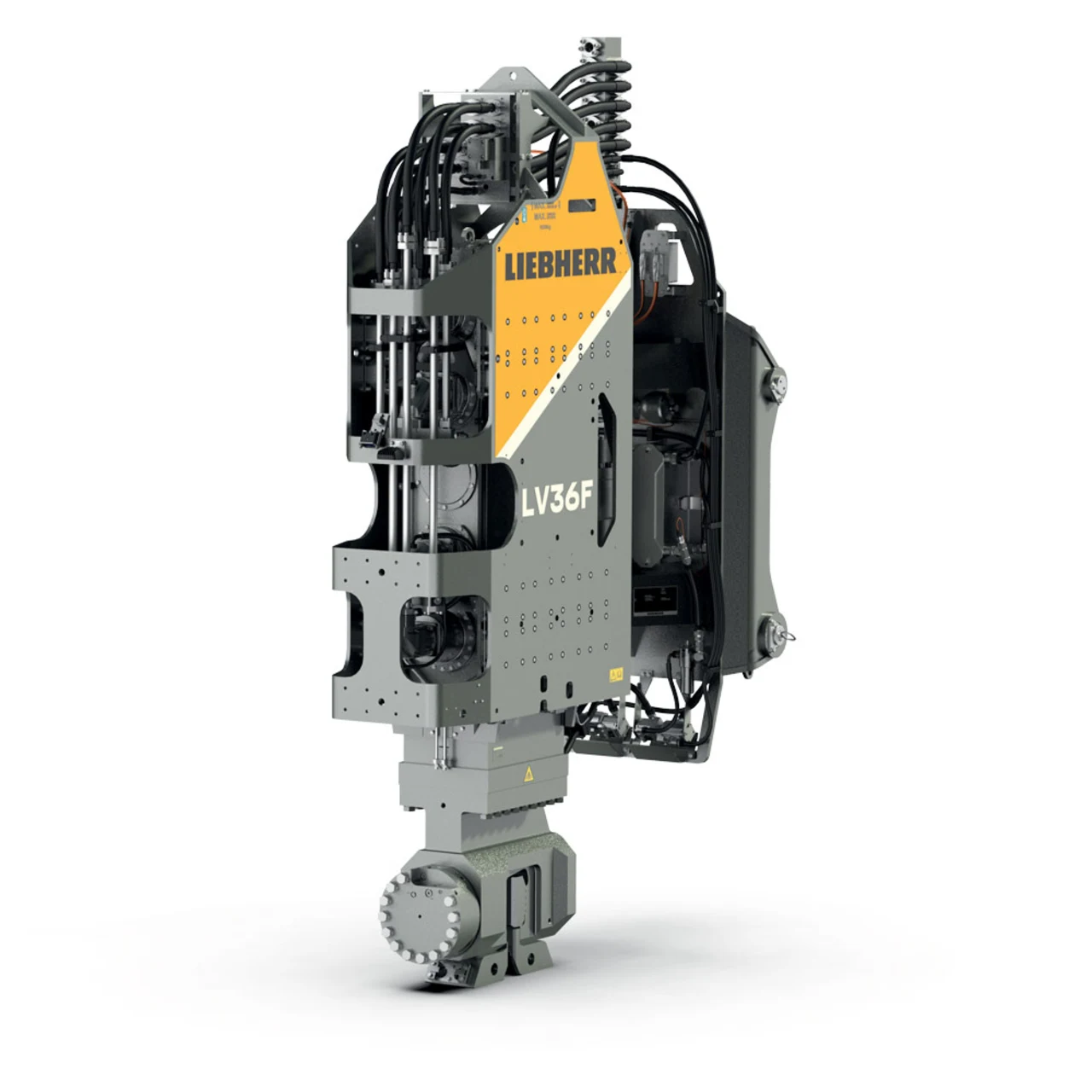

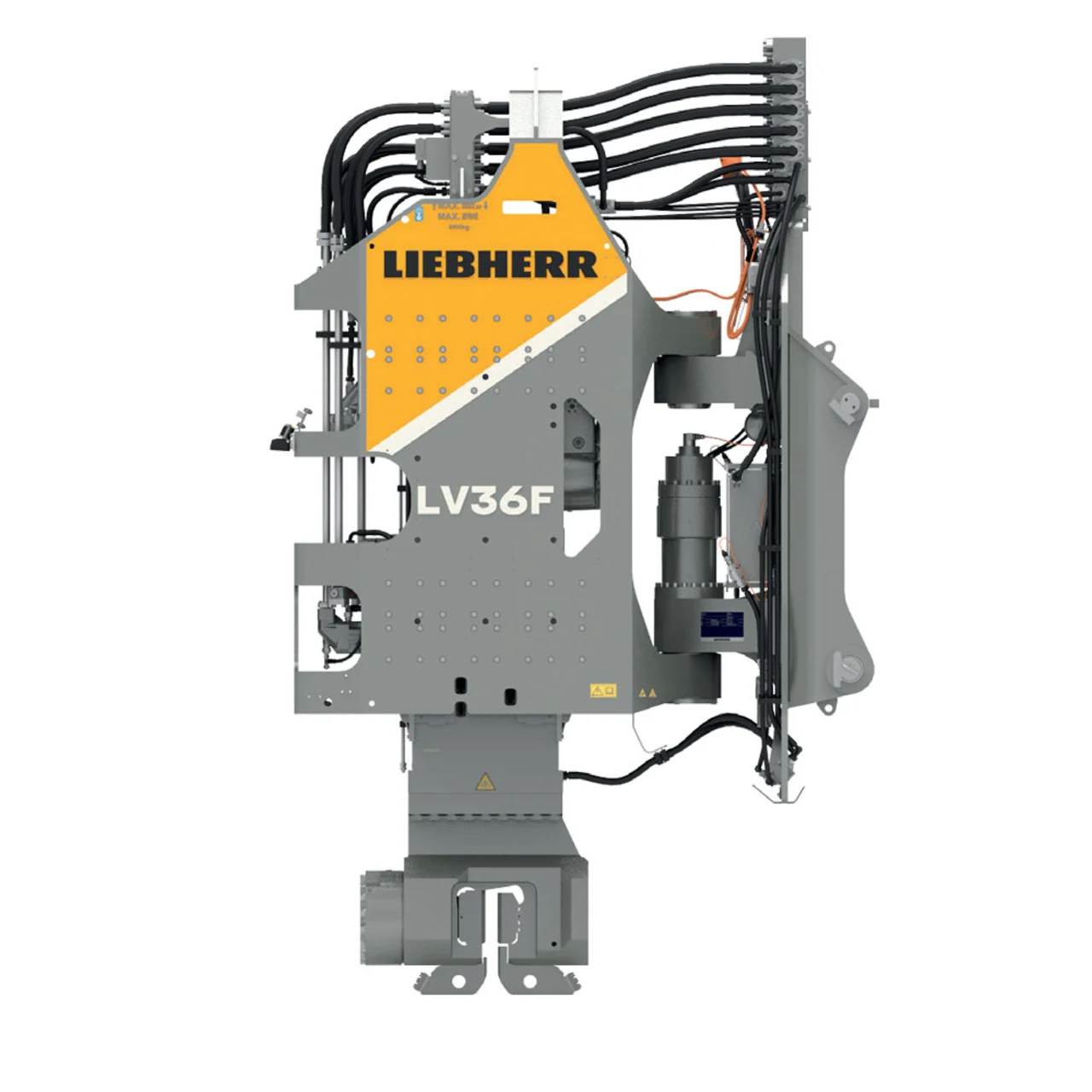

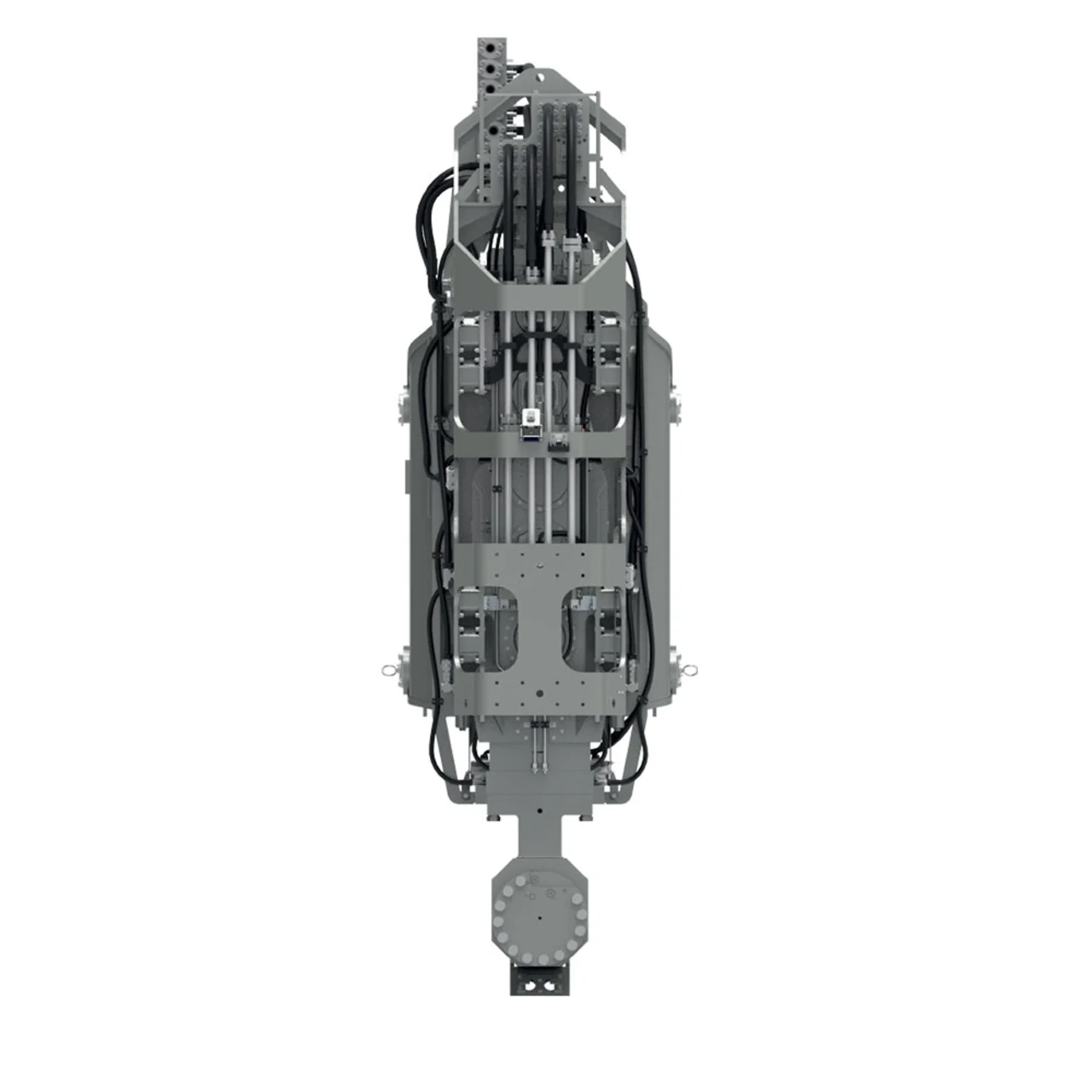

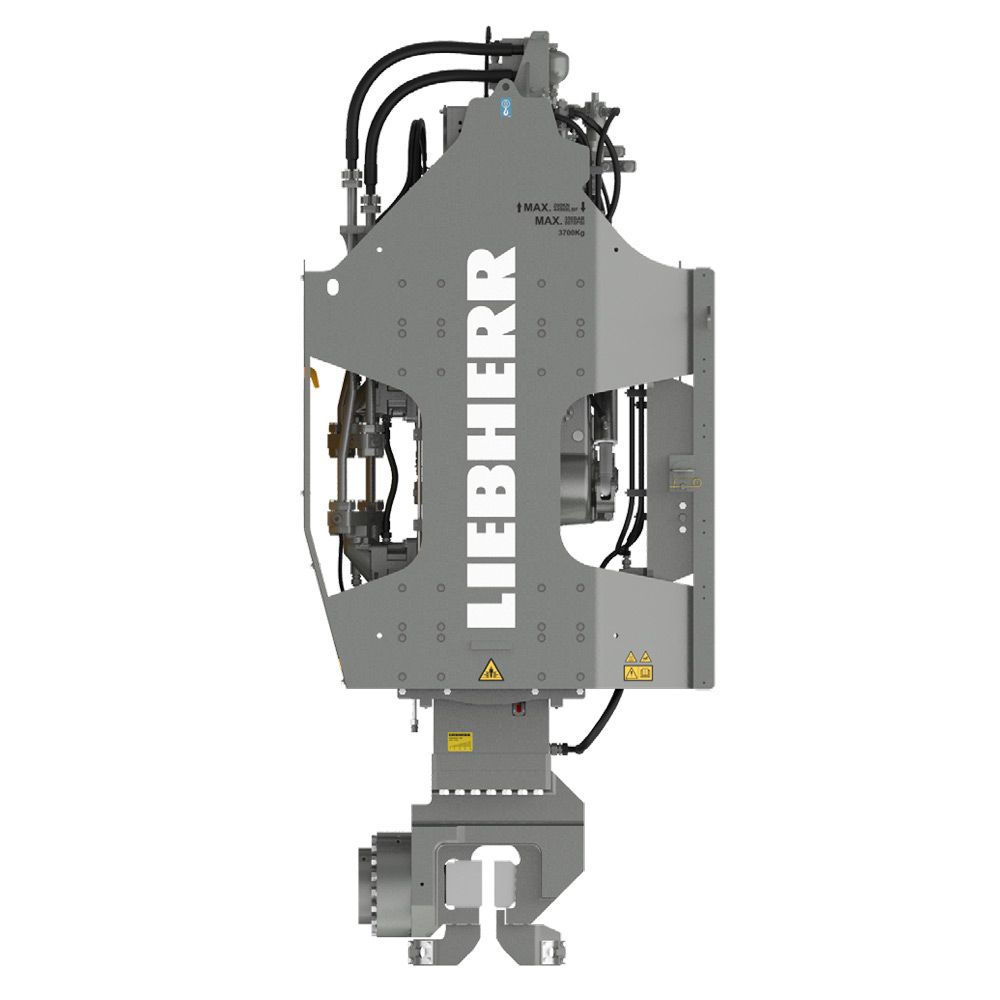

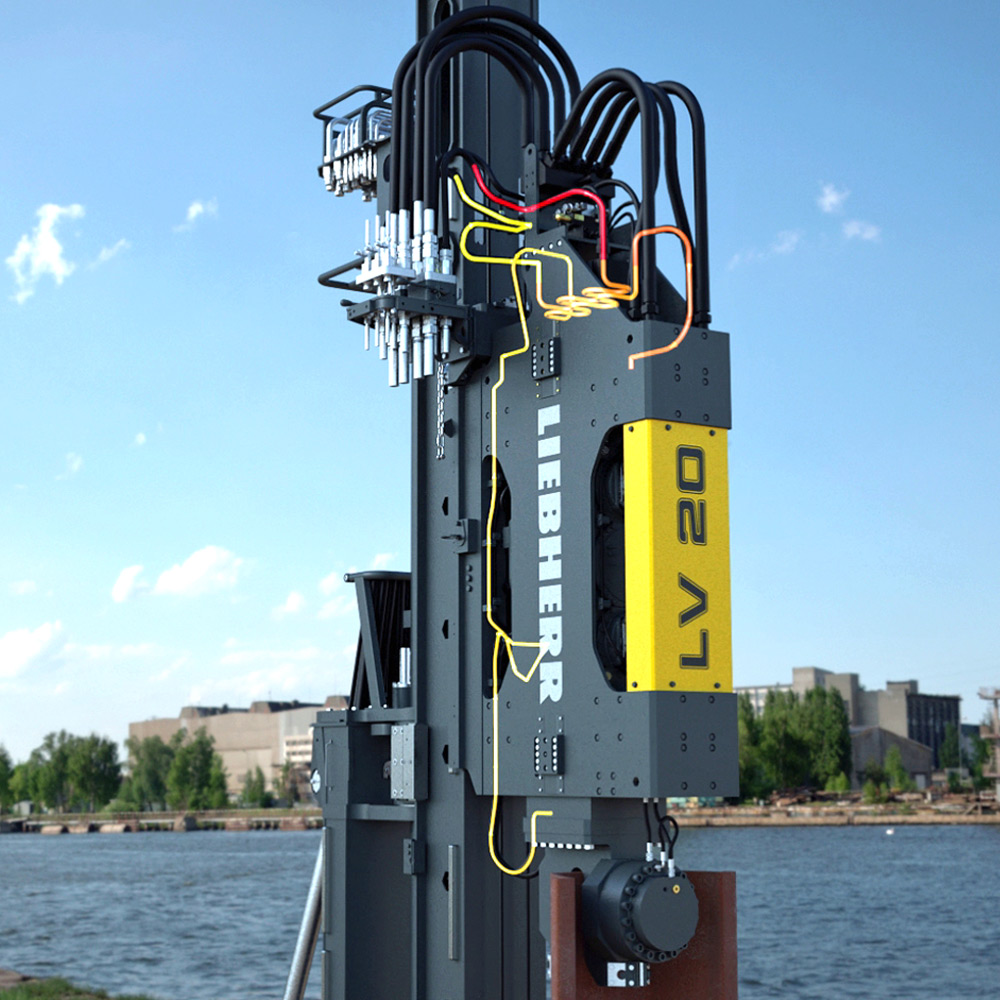

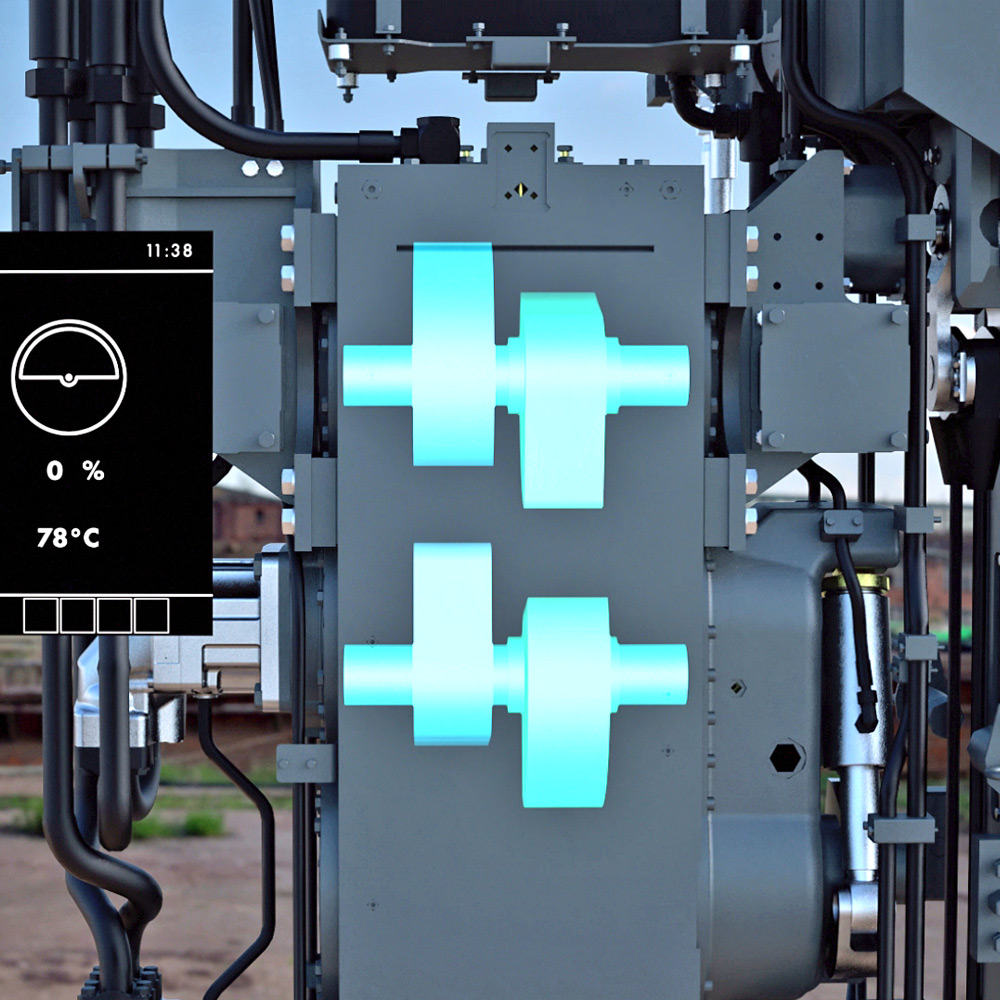

Vibrator LV 36 F

Vibrator slim design

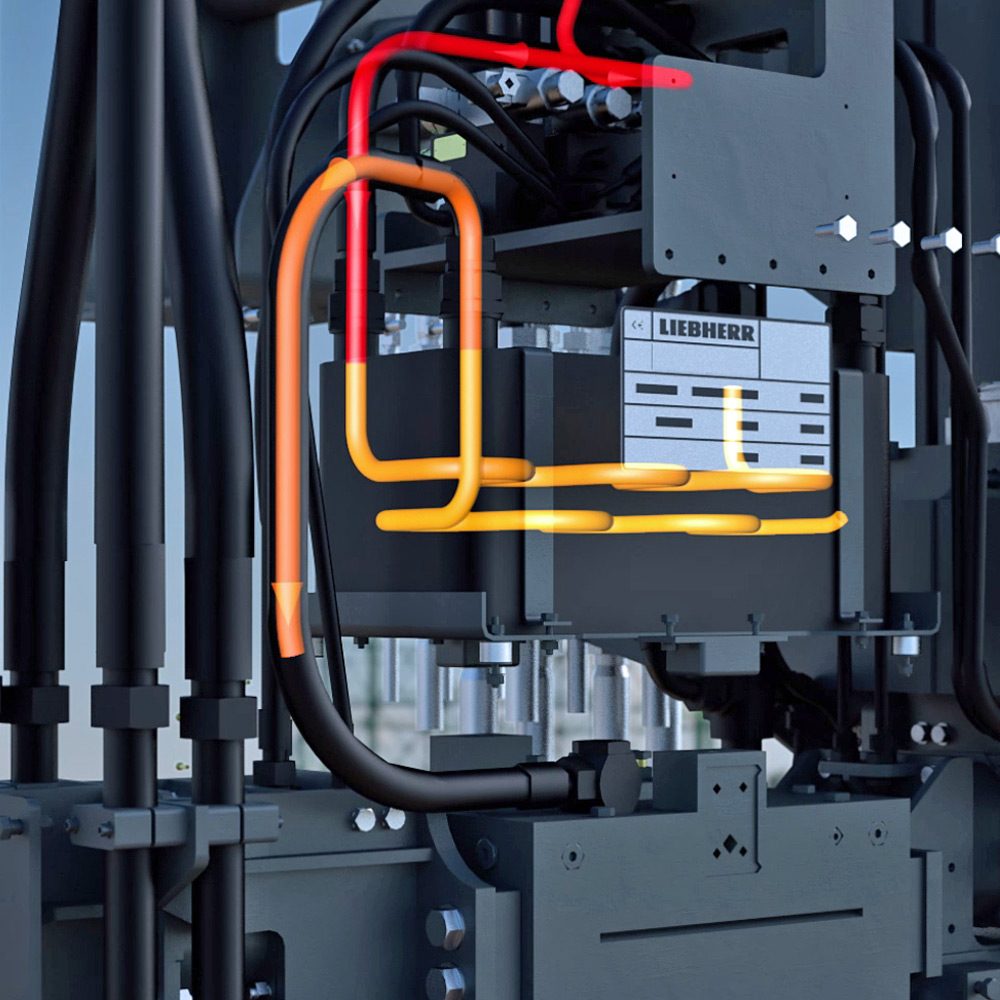

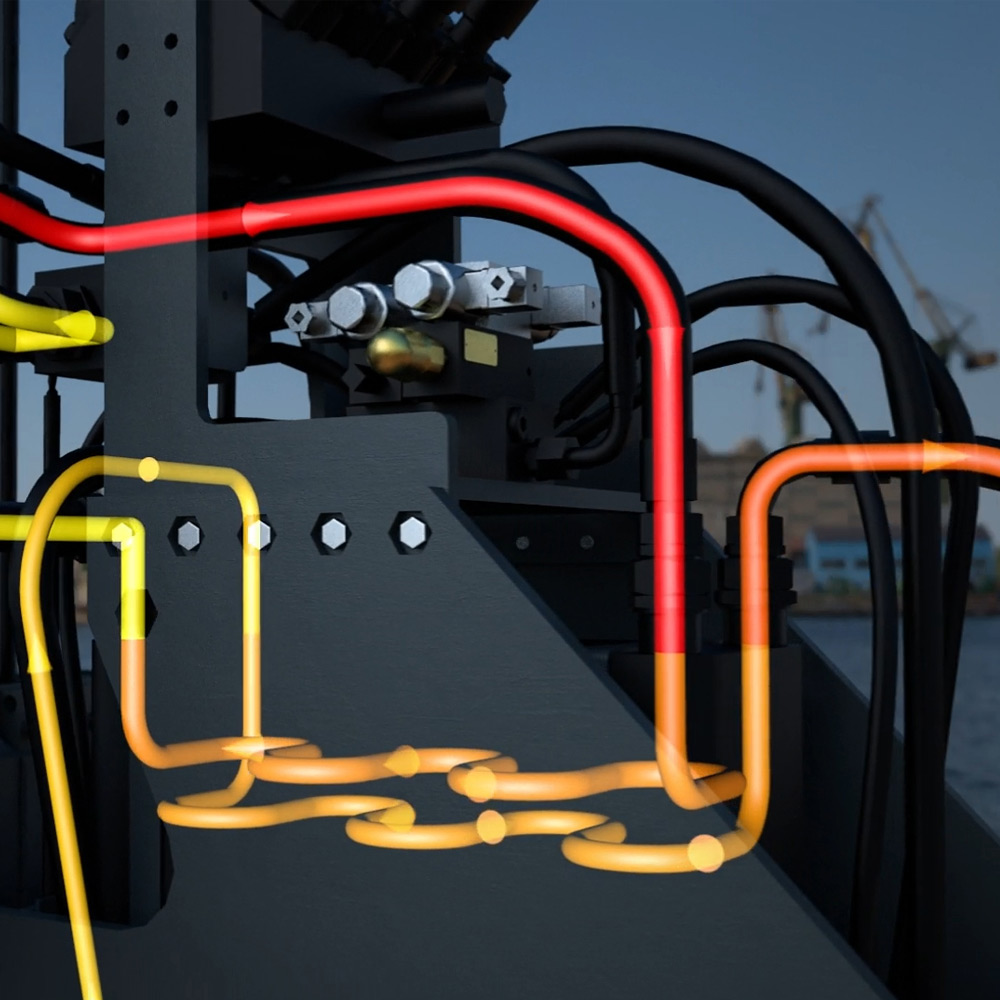

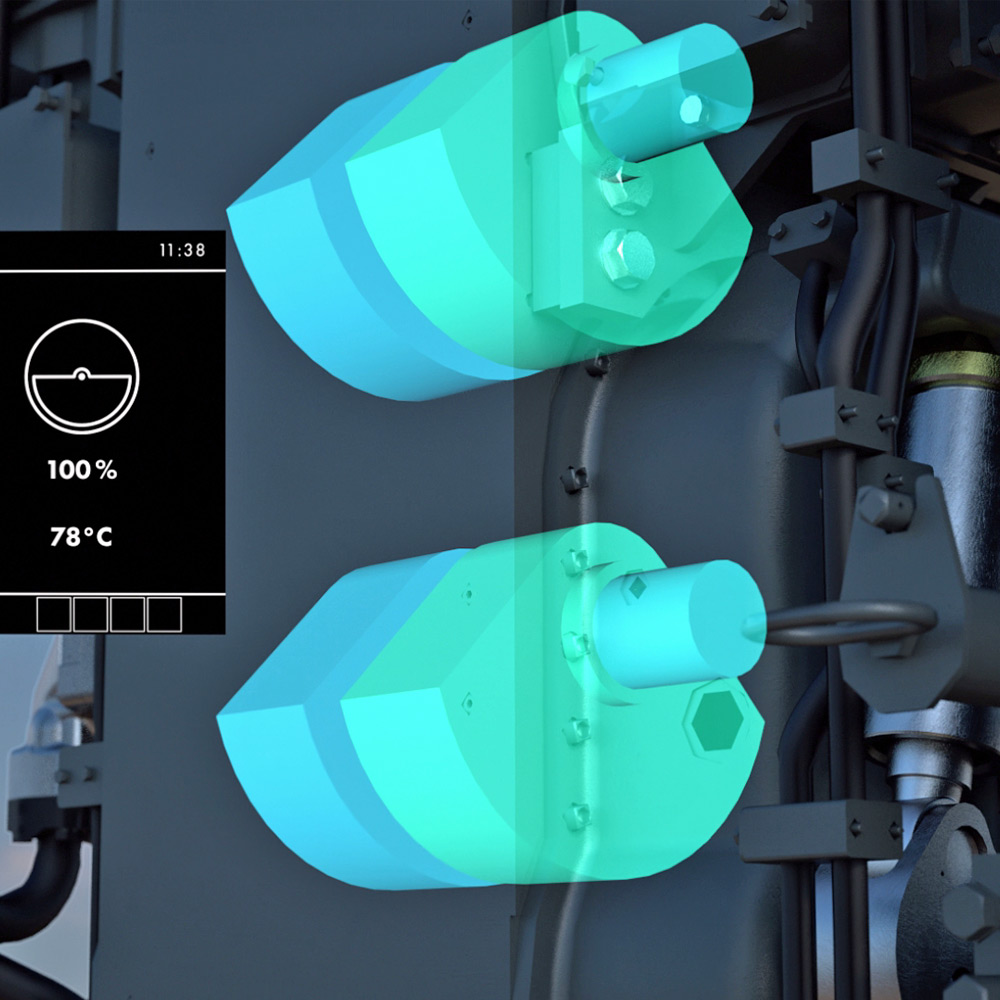

The high-frequency vibrator LV 36 F is specially designed for all common methods of soil improvement. This includes the installation of vibro-replacement columns or vibrated cast-in-place piles. The flexible suspension of the exciter block in the yoke counterbalances the angular errors between the piling element and the leader, which is unavoidable in this application. This also minimises the loss of performance as well as the wear on all parts.

Eccentric moment - 0 - 36 kgm

0 - 36 kgm

Max. centrifugal force - 1,910 kN

1,910 kN

Max. frequency - 2,400 U/min

2,400 U/min