Robust and flexible

Dive into the world of Liebherr-Components. As your reliable partner, we offer you high-quality industrial components for mechanical, hydraulic and electrical drive technology, as well as control technology — as individual components or complete solutions. Our extensive product range stands out in particular with its robust design and flexible use in a wide variety of industries and applications. As part of the Liebherr Group, we offer synergy effects from various product areas and develop innovative solutions in close co-operation with you, to meet all your requirements.

Our solutions

Components, systems and products

Durable products thanks to robust design

Long-term experience in various industries

End-to-end product & service portfolio

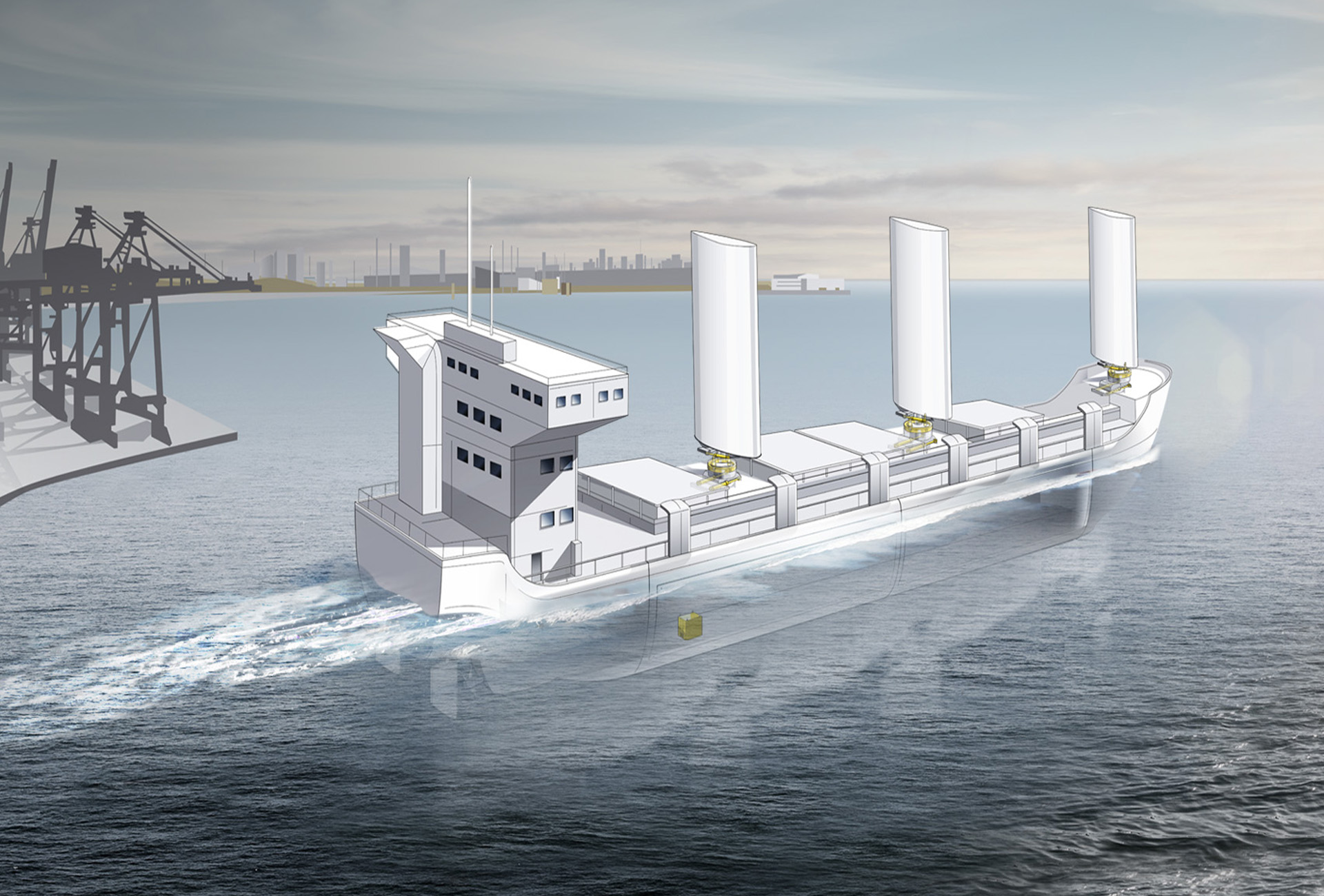

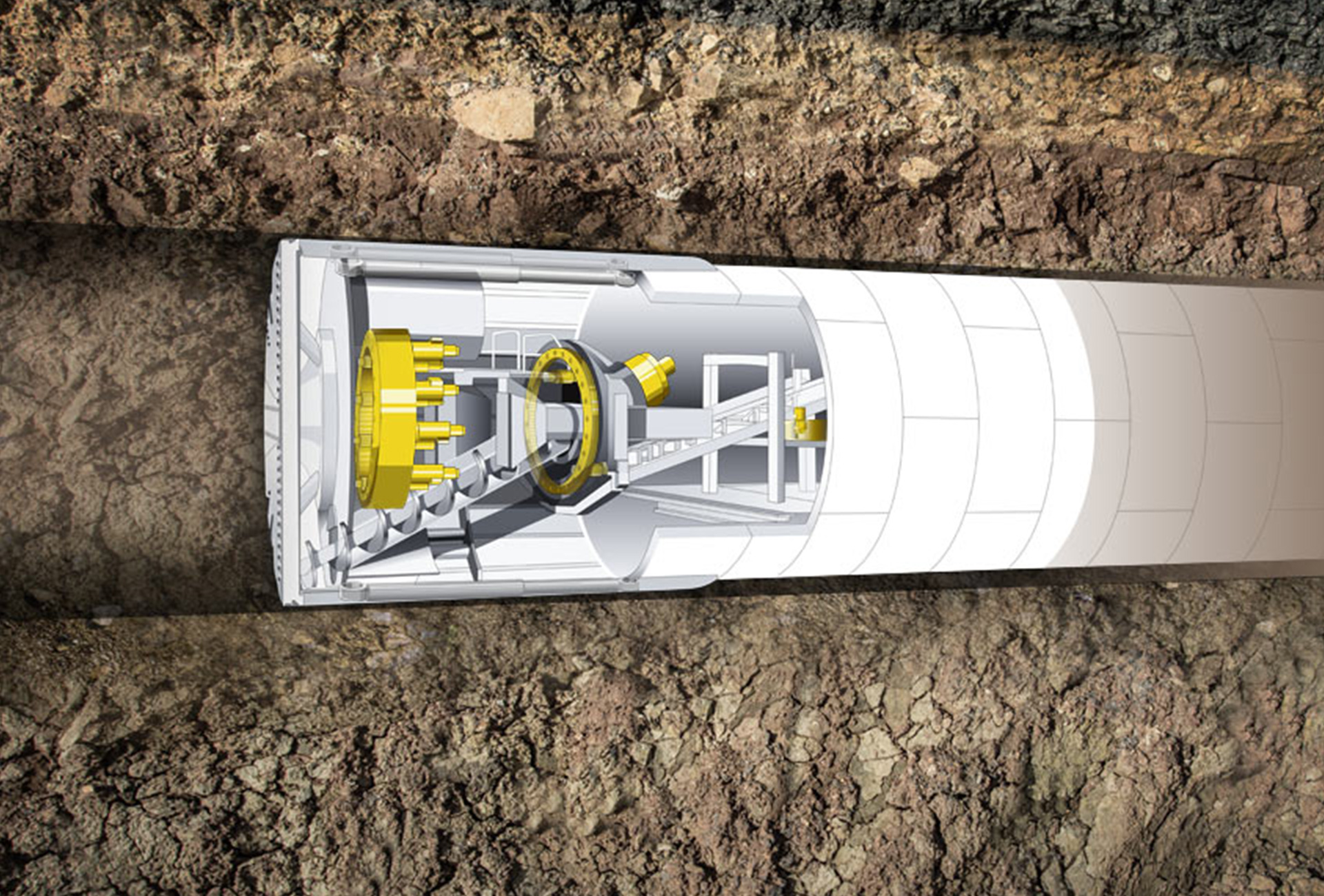

Versatile, reliable and indispensable: Our solutions for the industry

Our industrial components are used in cranes, construction machinery, mining, shipping, wind turbines, vehicle technology, transportation, just to name a few. Our aim thereby is to offer innovative solutions for different applications from one single source.

Maximum performance and minimum downtime: Discover our wind and mining after-market service

For the wind and mining industry, Liebherr offers a comprehensive after-market service package to ensure the long-term performance of plants and machines. High-quality spare parts, reliable repair services, and extensive expertise enable optimal equipment availability and maximum efficiency. Rely on a global network and many years of experience to keep your operations running at the highest level at all times.