LTM 1230-5.1

Mobile crane

LTM 1230-5.1 - Long, powerful and versatile!

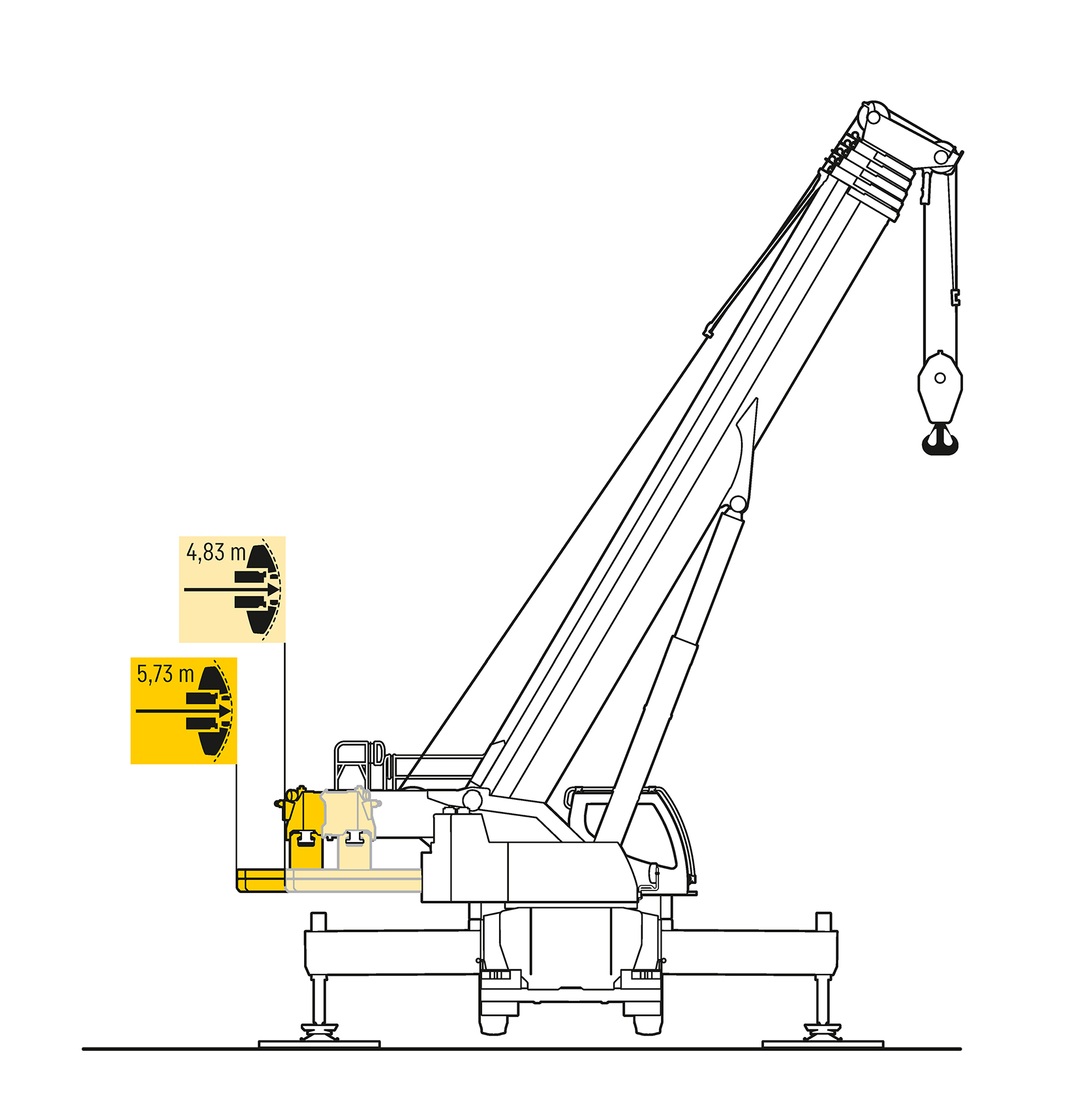

Our crane experts made the multi-award-winning VarioBase® support technology the focal point of the structural steel design for this crane. This means that the LTM 1230-5.1 is the first to have an asymmetrical support base. VarioBase® means that it is now possible to generate particularly high lifting capacities, particularly at the rear working area, over the supports – calculated in real-time by the LICCON controller. VarioBase® Plus is the combination of VarioBase and an asymmetrical support base. Furthermore, the LTM 1230-5.1 has an extremely long telescopic boom. And it also sets new standards in terms of lifting capacity. With lattice extensions, the maximum hook height has been increased by around 10 percent compared to its predecessor. The 5-axle mobile crane is therefore ideal for working with the boom fully raised and at large hook heights, for example for erecting tower cranes or maintenance work for wind turbines.

Max. load capacity - 230 t

230 t

Telescopic boom - 75 m

75 m

Max. hoist height - 111 m

111 m

Max. radius - 86 m

86 m

Number of axles - 5

5

What's inside

Maximum lifting capacity: 230 t / 275 US t

Maximum height: 111 m / 364 ft

Hoist more: VarioBase® Plus

Economical and flexible: VarioBallast®

Green: ECOdrive

Photo gallery

Technical data

| Max. load capacity | 230 t |

| at radius | 3.00 m |

| Telescopic boom from | 12.70 m |

| Telescopic boom up to | 75.00 m |

| Lattice jib from | 3.40 m |

| Lattice jib up to | 43.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 400 kW |

| Number of axles | 5 |

| Drive/Steering standard | 10 x 6 x 10 |

| Drive/Steering option | 10 x 8 x 10 |

| Driving speed | 85.00 km/h |

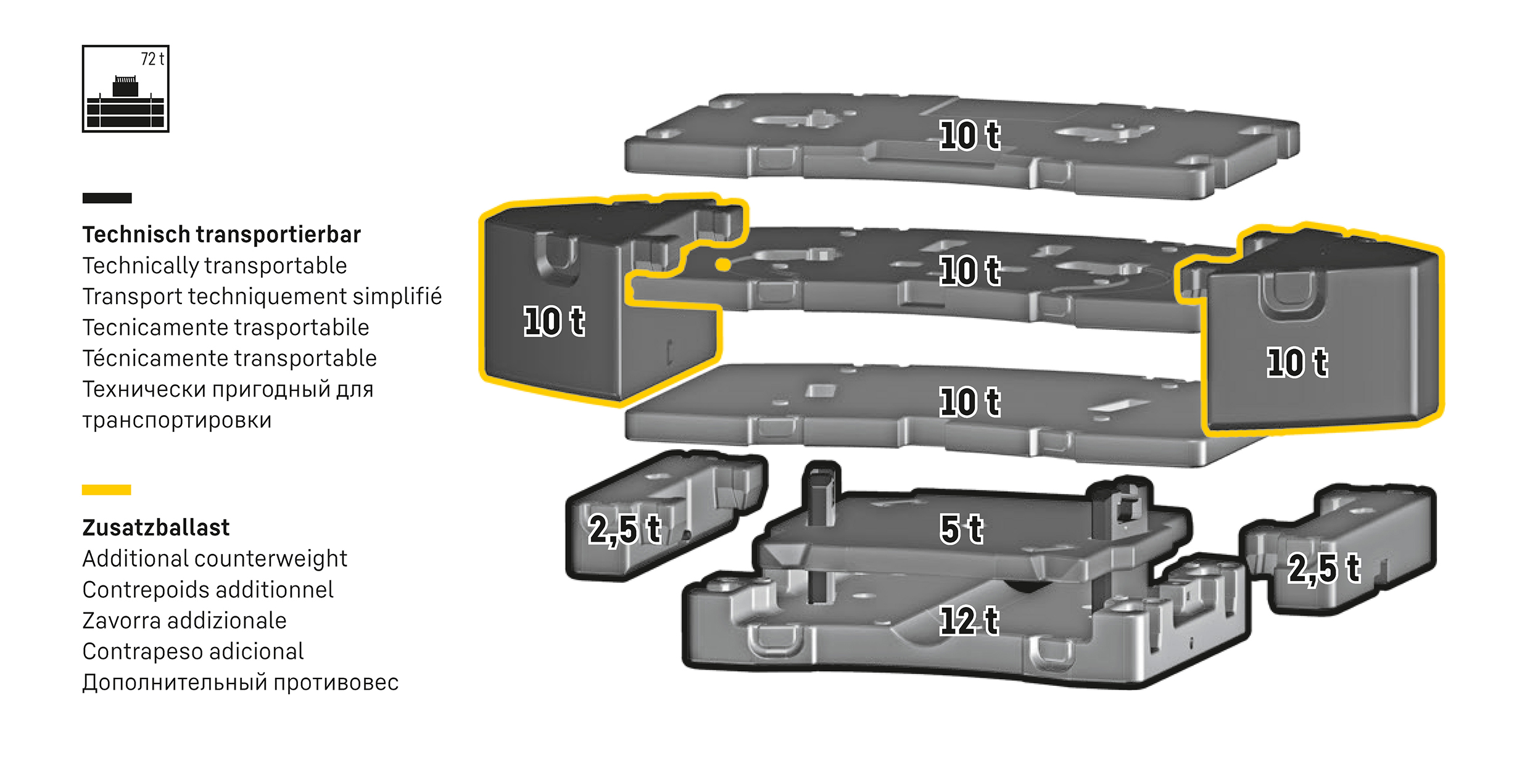

| Total ballast | 72.00 t |

Downloads

Videos

Long, powerful and versatile

A crane trip to the epicentre of Scotch whisky

A pelican undergoing maintenance

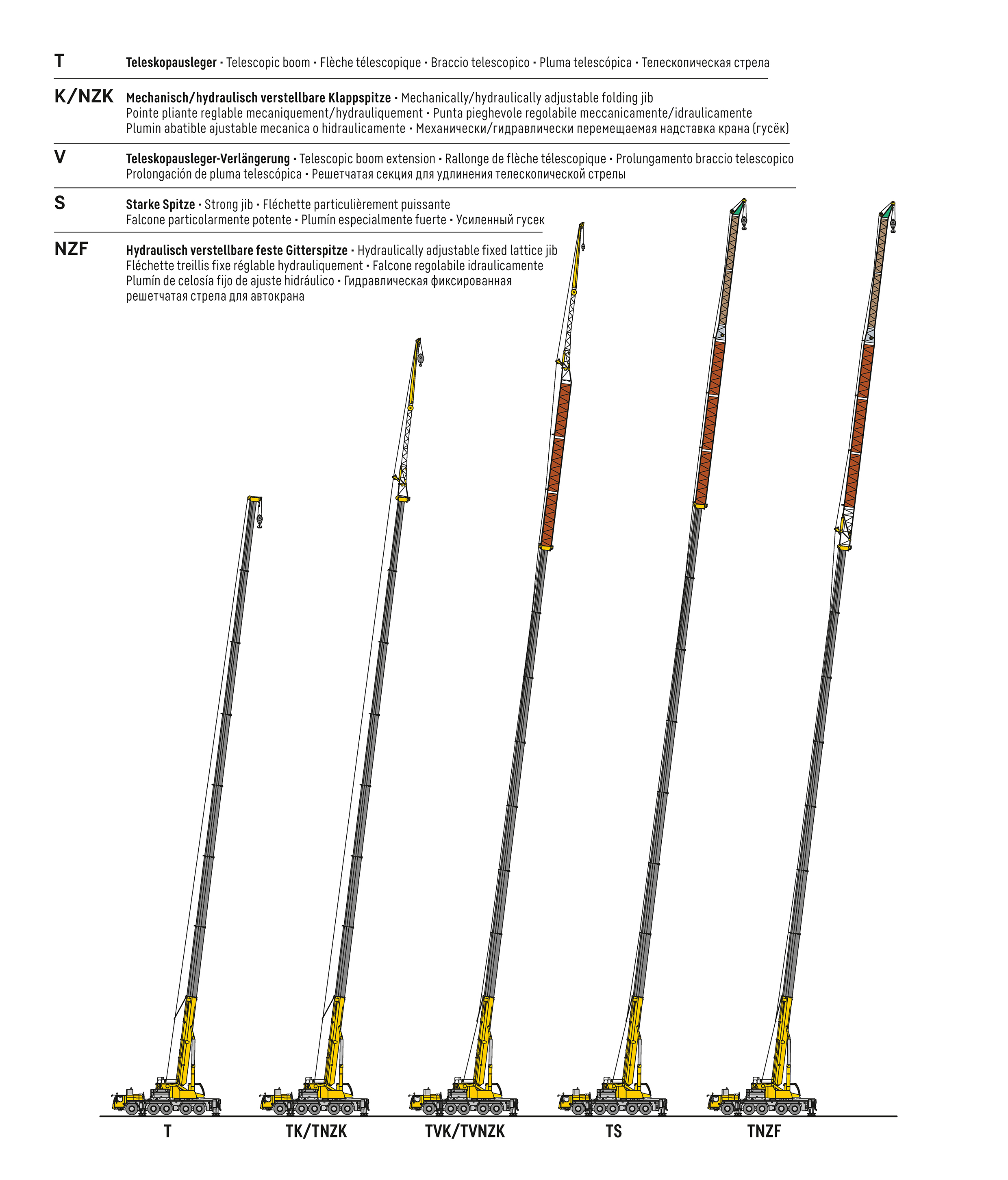

Boom/jib combinations

Boom/jib combinations

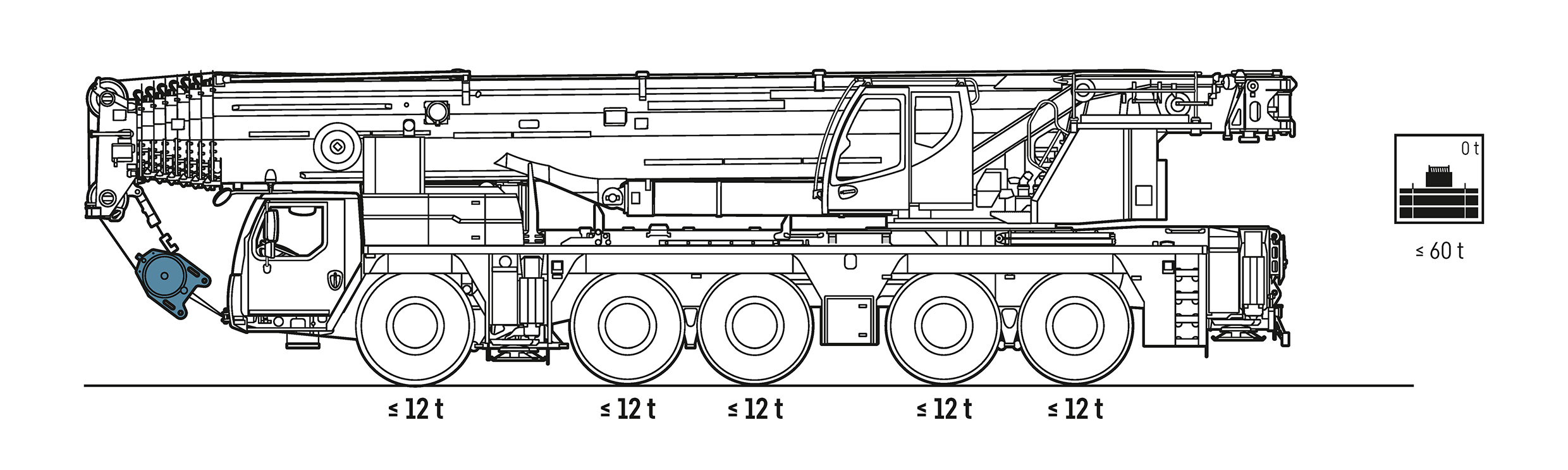

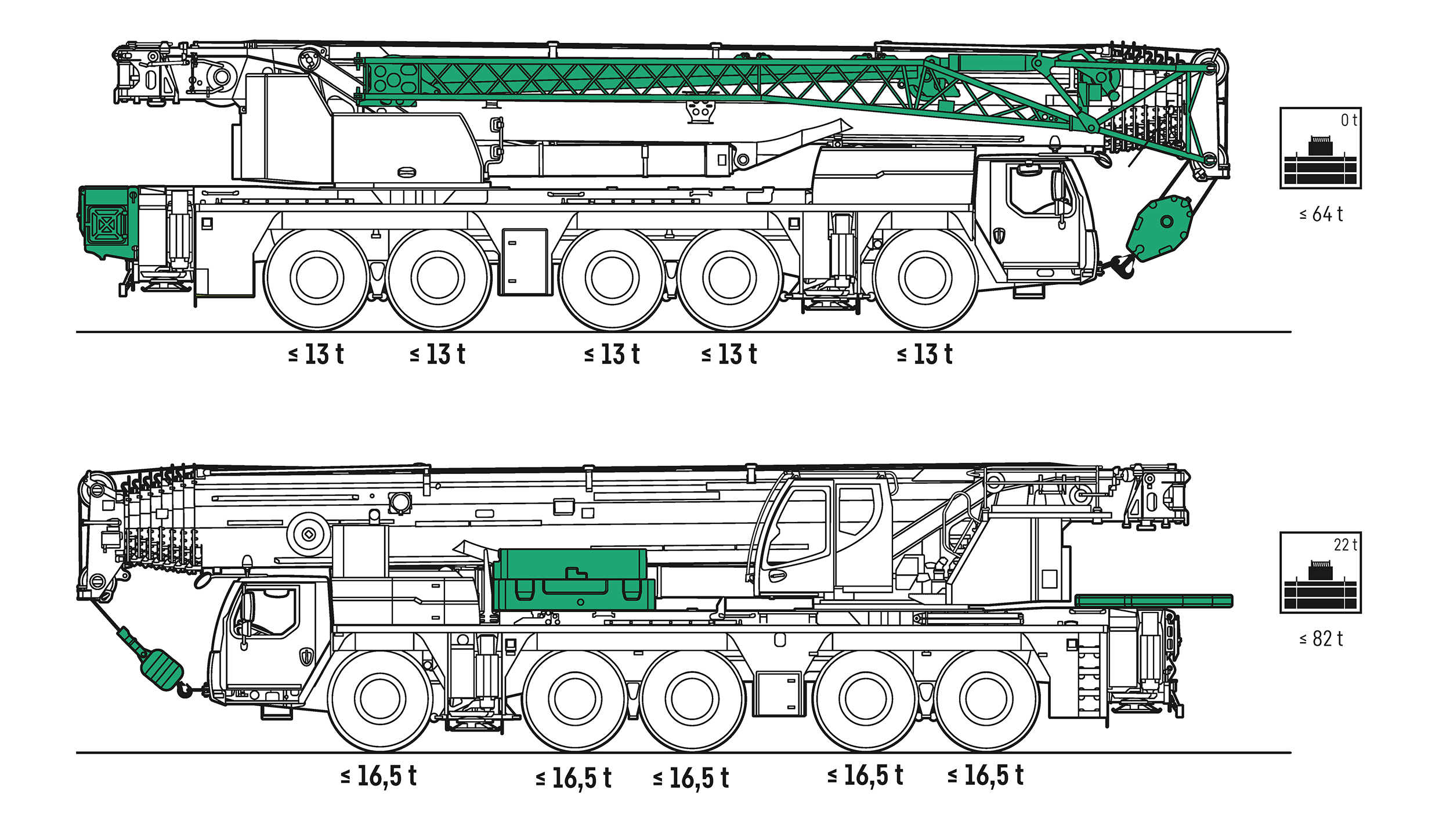

Driving conditions

On-road driving

Jobsite driving

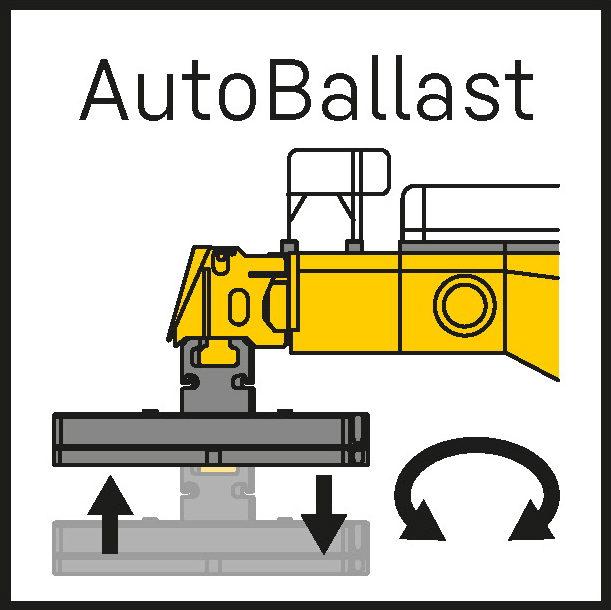

Ballast systems

Counterweight

VarioBallast: Counterweight radius

Technology

ECOmode

ECOdrive

Single-engine concept

Hillstart-Aid

VarioBase® Plus

VarioBallast® (mechanical)

AutoBallast

WindSpeed load charts