LTM 1160-5.2

Mobile crane

LTM 1160-5.2 - Efficiency coupled with massive lifting capacity.

The LTM 1160-5.2 delivers efficiency without compromising on performance. Its single-engine concept powers the crane’s superstructure from the undercarriage using a mechanical shaft. ECOmode and ECODrive technologies also help to reduce fuel consumption by up to 10%. However, no compromises are accepted when it comes to the lifting capacities and boom of the 5-axle crane – a range of boom configurations ensure it is very flexible in action, whilst the VarioBallast® system enables the crane to manage high lifting capacities with the large ballast radius and constricted sites with the small radius – no problem!

Max. load capacity - 180 t

180 t

Telescopic boom - 62 m

62 m

Max. hoist height - 99 m

99 m

Max. radius - 78 m

78 m

Number of axles - 5

5

What's inside

Maximum hook height - 99 m:

Variable support:

Economical and flexible – VarioBallast®:

Single-engine concept:

Efficient:

Photo gallery

Technical data

| Max. load capacity | 180 t |

| at radius | 2.50 m |

| Telescopic boom from | 13.10 m |

| Telescopic boom up to | 62.00 m |

| Lattice jib from | 2.90 m |

| Lattice jib up to | 40.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 400 kW |

| Number of axles | 5 |

| Drive/Steering standard | 10 x 6 x 10 |

| Drive/Steering option | 10 x 8 x 10 |

| Driving speed | 85.00 km/h |

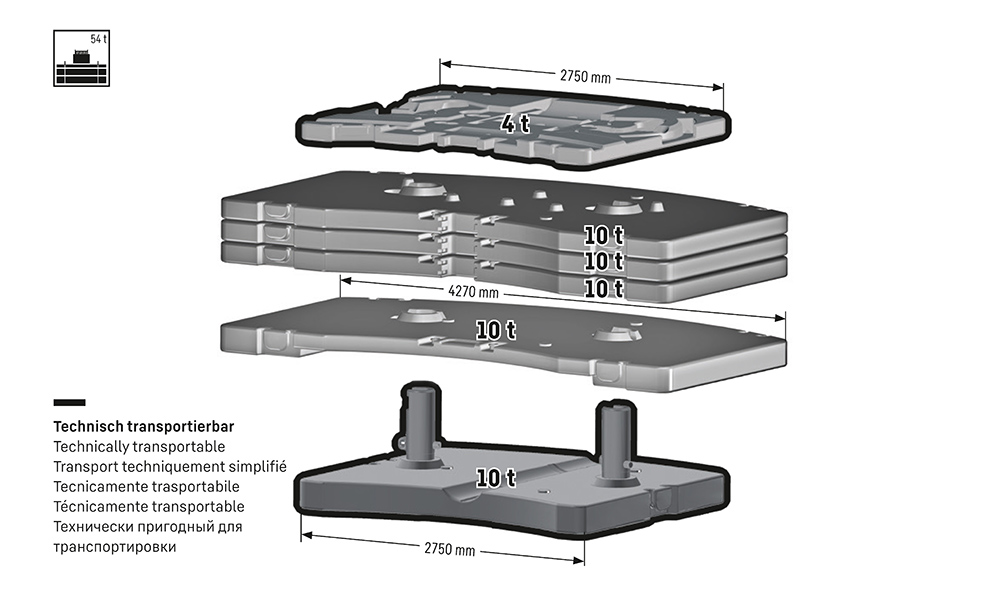

| Total ballast | 54.00 t |

Downloads

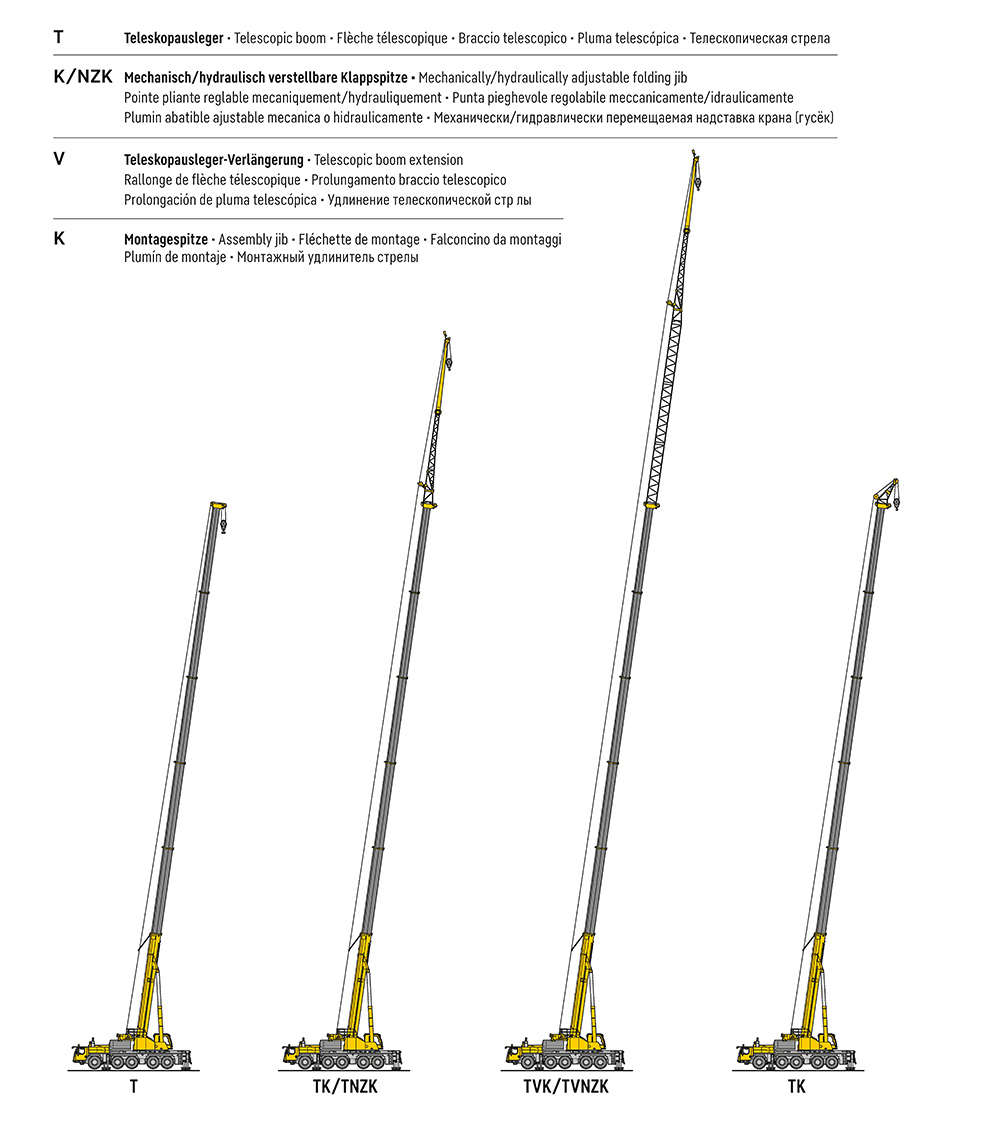

Boom/jib combinations

Boom/jib combinations

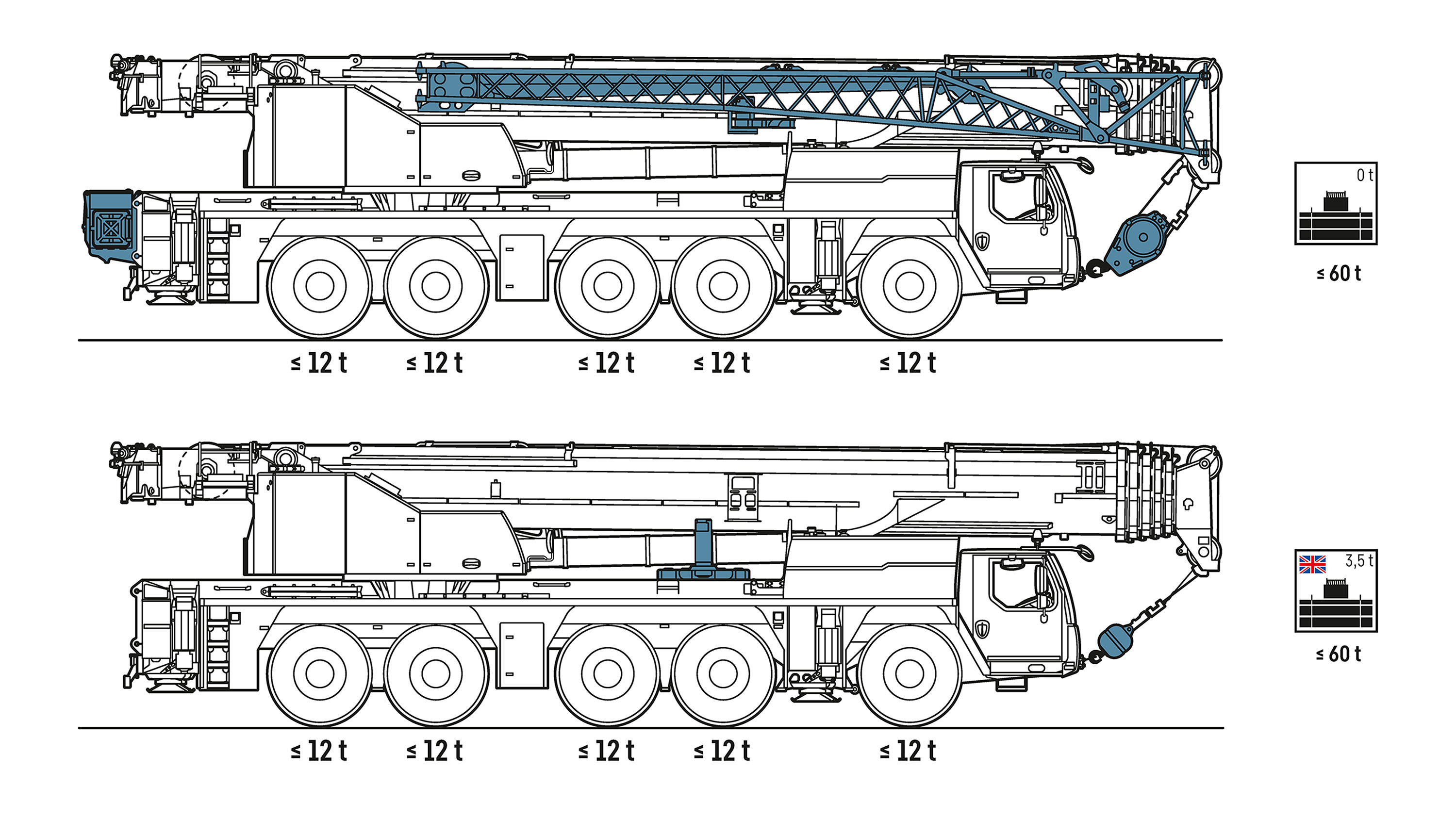

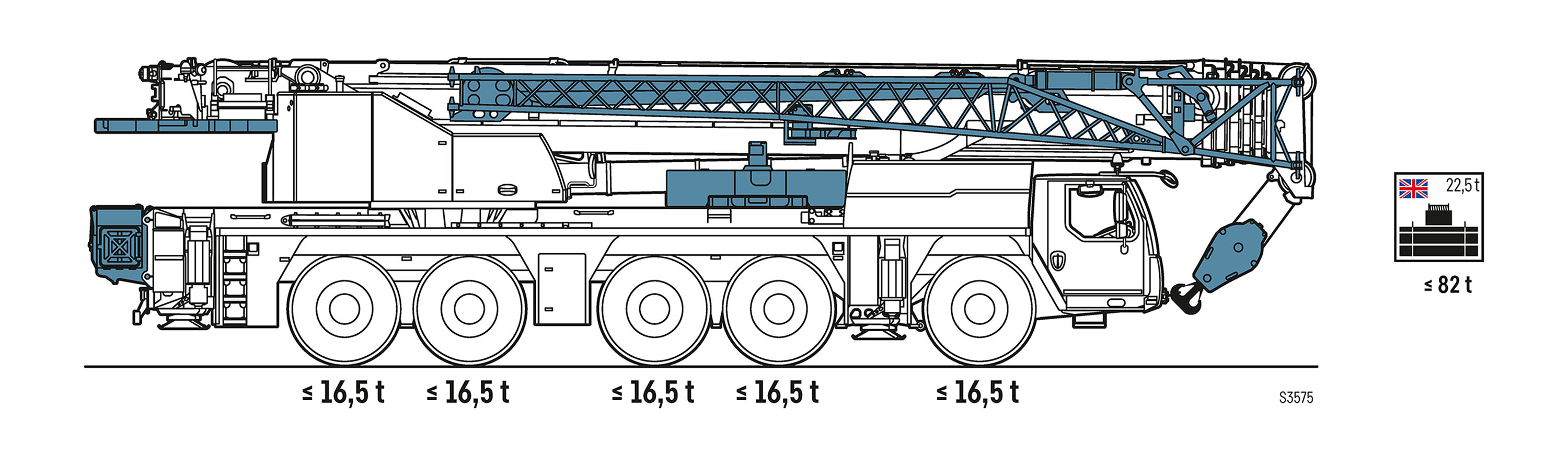

Driving conditions

On-road driving

Jobsite driving

Ballast systems

Counterweight

Technology

ECOmode

ECOdrive

Single-engine concept

Hillstart-Aid

VarioBase®

VarioBallast® (mechanical)