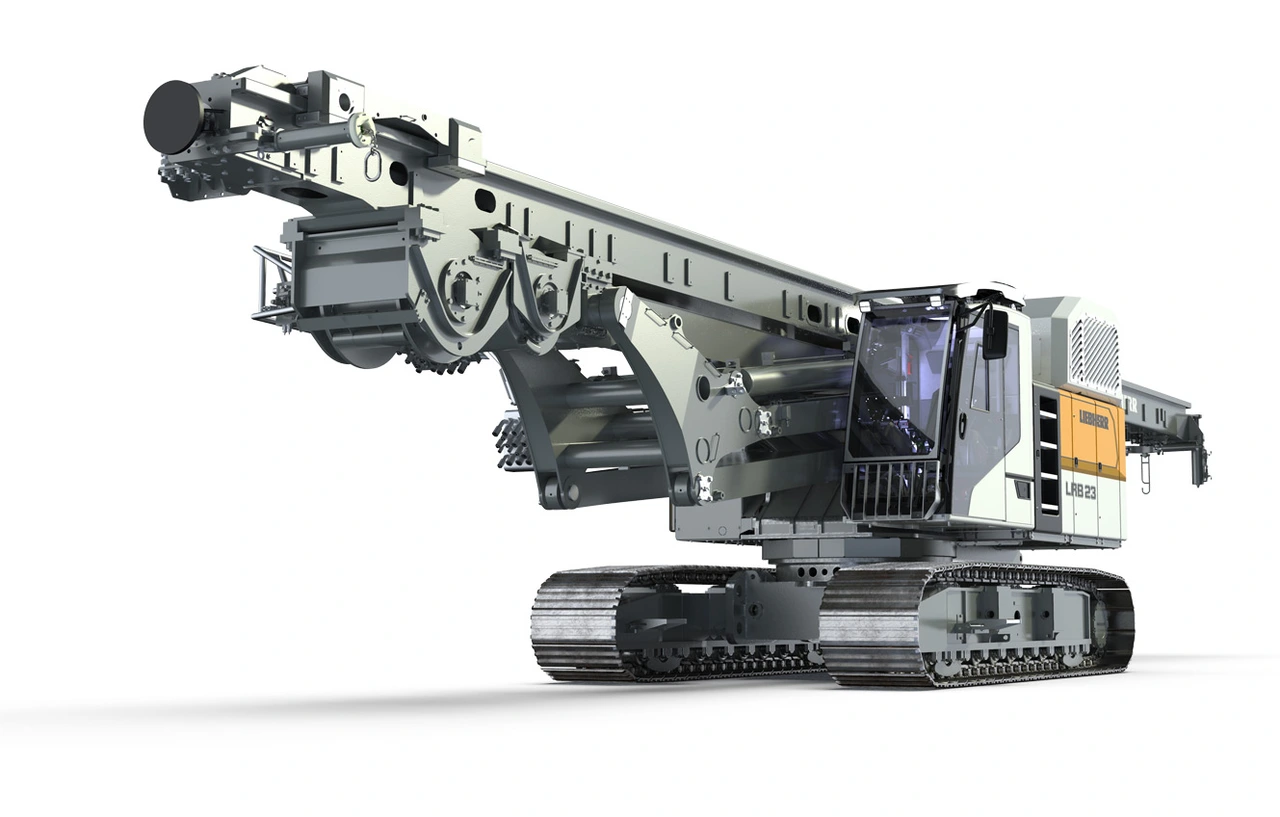

LRB 23

Piling and drilling rig (LRB series)

The compact piling and drilling rig type LRB 23 closes the gap between the LRB 16 and the long-proven LRB 355. An impressive engine output provides the all-rounder with the necessary capacity for all common deep foundation work, such as Kelly drilling, double rotary drilling, full displacement equipment and continuous flight auger, as well as soil mixing and applications with a vibrator or hydraulic hammer.

Operating weight - 72.6 - 78.5 t

72.6 - 78.5 t

Max. torque - 300 kNm

300 kNm

Max. crowd force - 320 kN

320 kN

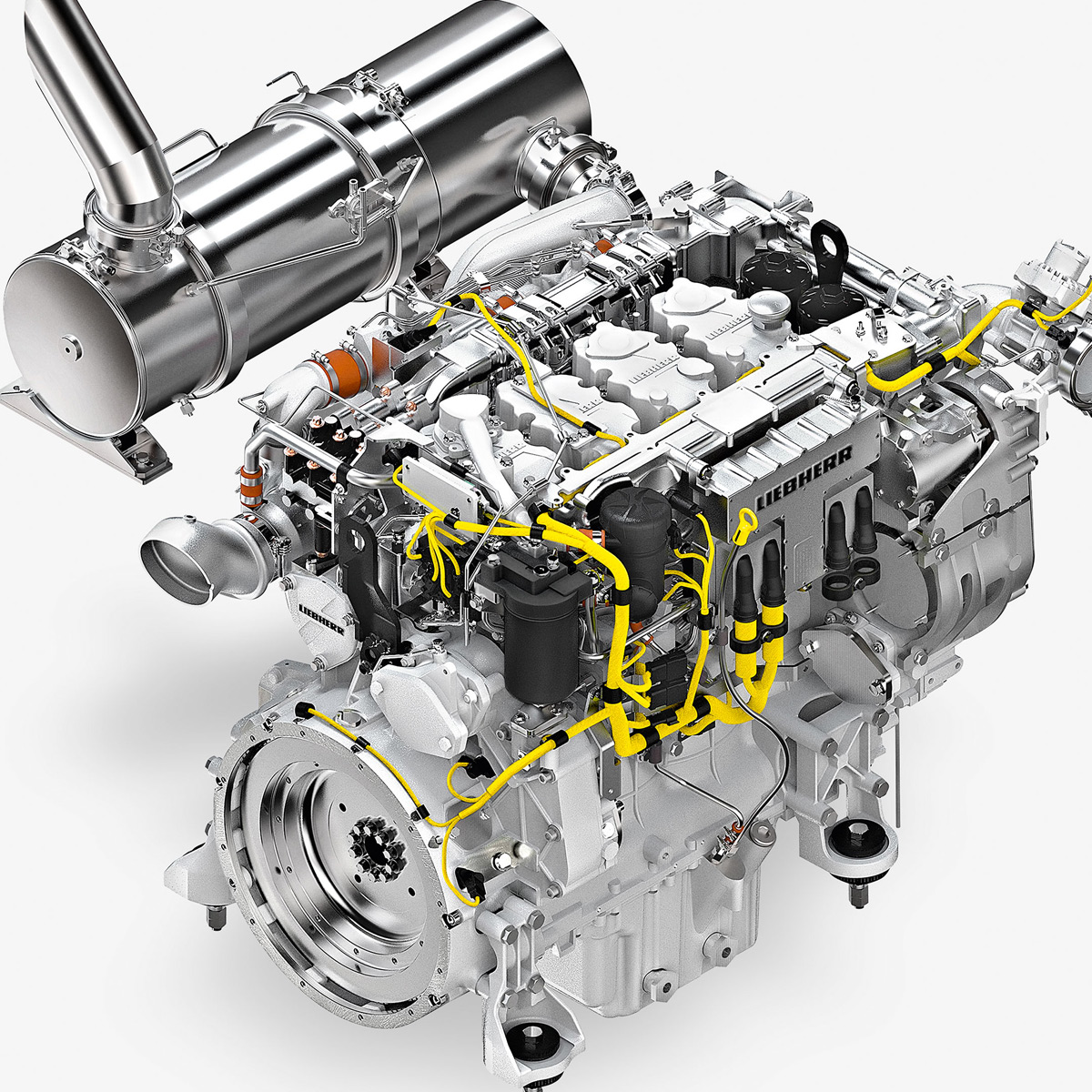

Engine power - 600 kW

600 kW

Pile driving with vibrator slim design, max. pile length - 22.0 m

22.0 m