The future is fibre rope

Innovation and progress have shaped lifting for thousands of years, from the natural fibre rope used for the pyramids to the steel rope on modern construction sites. Fibre technology has undergone years of field testing and sets new standards in terms of lifting capacity, stability and weight – it’s a step into the future of lifting technology.

Success in figures:

~ 300 Fibre cranes sold

>30 % sales share

85 % repair rate*

2 % downtime rate**

The fibre rope success story

Vision put to the test

Field tests confirm the findings from test bench analyses regarding the exceptional robustness of fibre rope when exposed to sources of failure e.g. concrete edges. Fibre rope is less susceptible to damage due to the flexible cover surrounding the load-bearing core and, compared to steel rope, is more forgiving of significant errors in crane operation without rope damage being caused.

Minimised downtimes

Rope damage can’t always be avoided, even on today’s construction sites. Thanks to our innovative, flexible and competent services, we are able to restore the fibre rope’s full performance capability, and in most cases directly on site.

In harmony with our customers

Innovation paired with a passion for delivering the highest quality are values that drive our company every day. A combination of experience gained in recent years, feedback from construction sites and the needs of our customers have influenced three key developments.

If a fibre rope is irreparably damaged at one point, it can be shortened and re-bonded again so that the rope can continue to be used at a reduced length. The new end connection can be fitted both on site and at our factory – a flexible solution that fits in with site conditions and can be specified by our customers. The combination of rope shortening and fibre repair kit achieves a repair rate not possible with steel rope.

We are increasing overall service life from 10 to 14 years. This covers duration of use and storage time. Rope wear is still indicated by the rope cover. The increase in overall service life is independent of the rope’s purchase date and also applies to all ropes in the field.

When you buy a Fibre crane, your options are open. The ability to convert to a steel rope crane gives you the security you need when investing in a technology that is new to you. And as believers in fibre technology, we also offer the option of converting a steel rope crane into a fibre version. This opportunity makes it easier to get started with our technology.

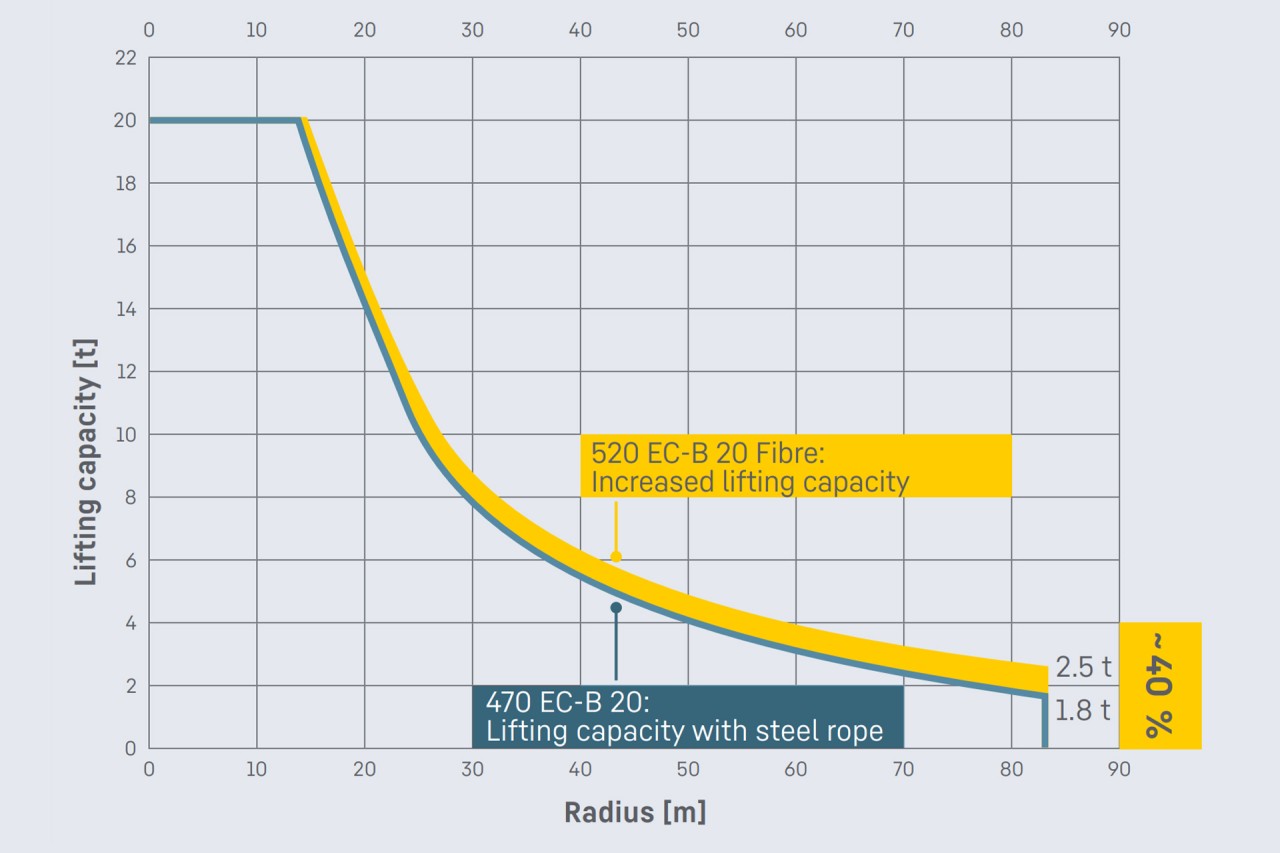

Strong arguments: 4 advantages through innovation

1. Simple handling

2. Cost-effective operation

3. Investment security

4. Efficient and responsible

1. Simple handling

“Working with the rope day-to-day is genuinely fantastic. Lubrication isn’t required so the crane needs less maintenance – and work gear stays clean.” Jochen Braunger, Service Technician

The new fibre rope is 80 % lighter than comparable steel rope, so replacement takes less time and needs fewer people. This saves installation costs and reduces downtime.

Fibre cranes are low maintenance and don’t require lubrication like steel rope cranes. This keeps the crane, assembly engineers and catwalks clean. Despite lubrication, steel rope cuts into the rope pulleys and then needs to be replaced. This task is a thing of the past with Fibre cranes.

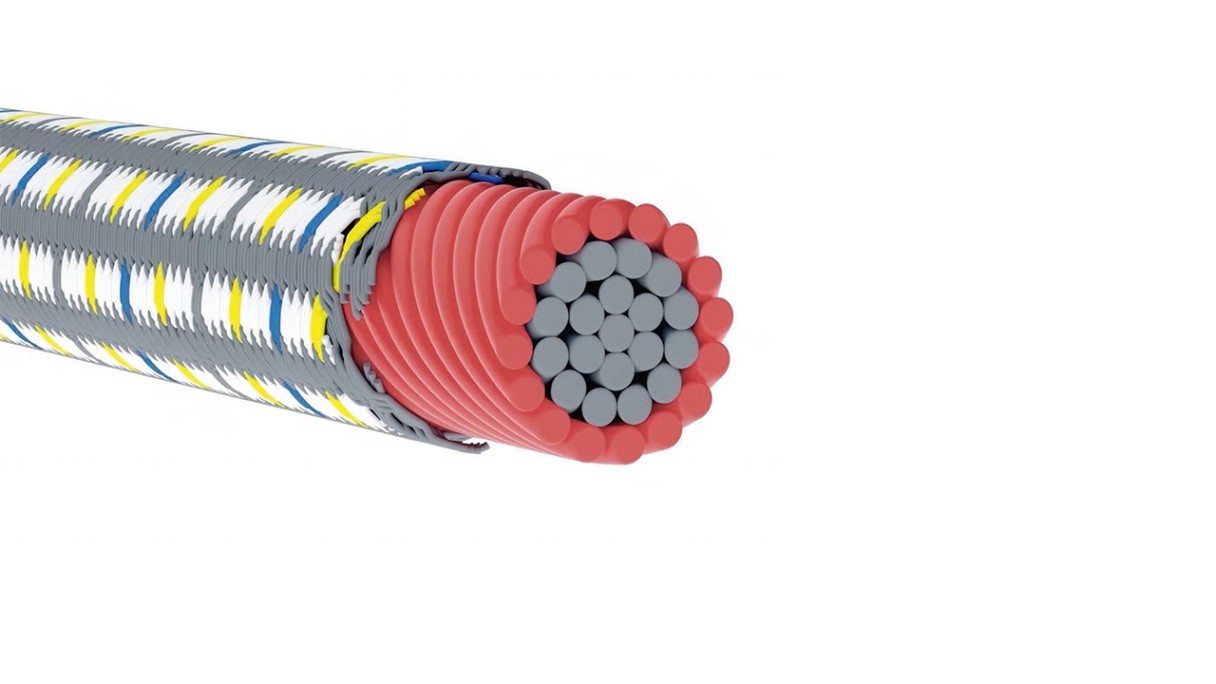

The fibre rope cover has a red signal layer to indicate the discard level, which becomes visible as the rope wears. This warning can also be seen at a distance. Plus, the rope is made of high-strength synthetic fibres, ruling out injuries caused by protruding wires.

The fibre rope core consists of high-tensile synthetic fibres that make it difficult for water to penetrate and therefore prevent corrosion. Undetected corrosion isn’t a risk, which increases safety, especially in maritime environments.

3. Investment security

“We want to convert our entire rental fleet to Fibre cranes here at Beutlhauser Holding GmbH. So we opt entirely for fibre technology when buying new machines and want to convert our existing cranes to fibre technology too.”

Benjamin Grillmeier, Head of Construction at Beutlhauser Holding GmbH

“Nagel Mietservice GmbH has exclusively chosen Liebherr tower cranes with fibre technology since 2020. Our rental customers specifically ask us for tower cranes with fibre technology.”

Nagel Mietservice GmbH

You can use virtually all steel rope crane components in the same way for your Fibre crane, except for the hoist drum, rope pulleys and hook block. This means that a high proportion of identical parts can be used, especially in the case of cost-intensive tower sections and substructures. The structural design of the Fibre crane is the same as that of its steel rope counterpart, so the only additional expertise required is for the fibre rope itself.

The flexibility of being able to convert a Fibre crane into a steel rope crane offers additional security when investing in fibre technology. Discover the benefits of fibre technology for yourself – and if you do decide to convert, we are happy to help.

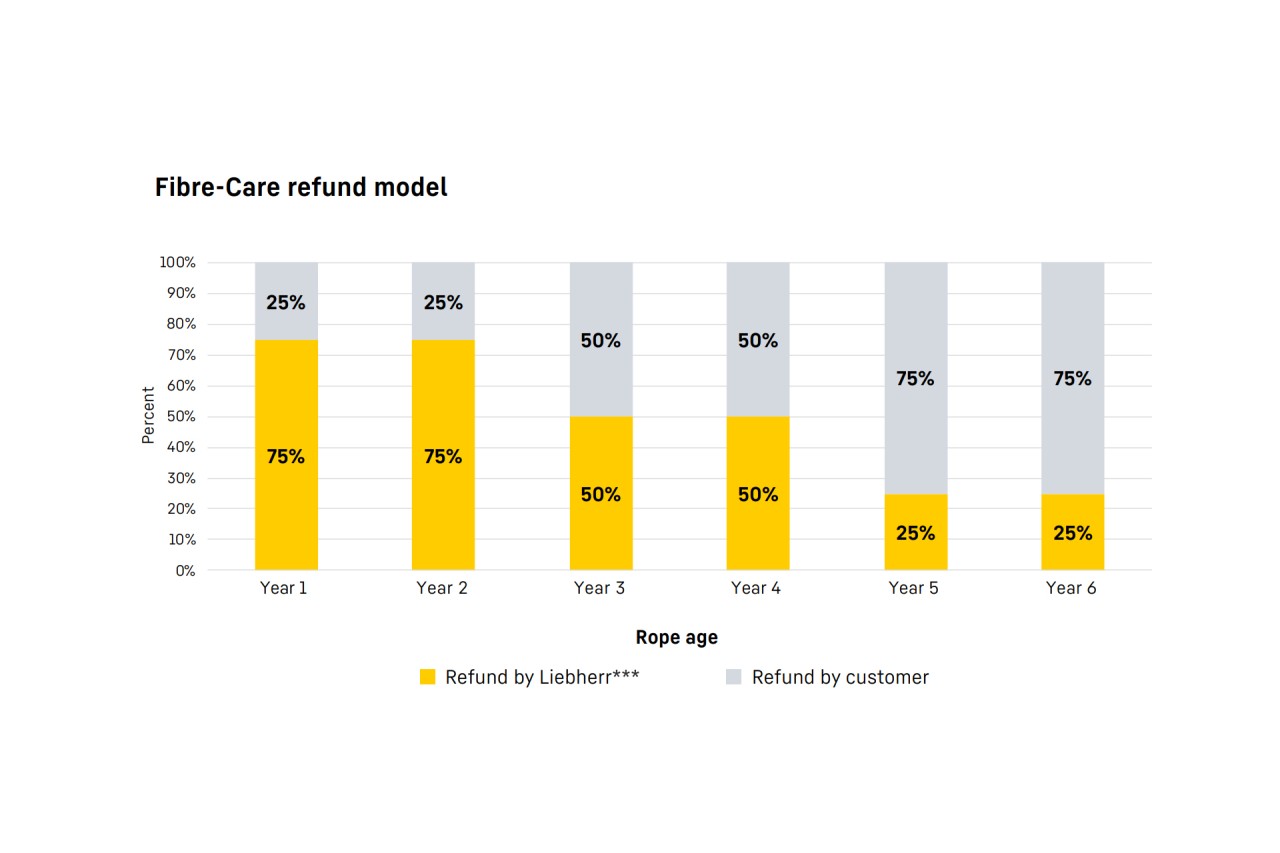

Consistent demand, a wealth of experience and internal optimisations, e.g. in fibre rope storage, make improvements possible. This results in an optimised service life to price ratio.

Our extended warranty is designed to give you additional security when using fibre rope. Low downtime rates coupled with our performance-orientated spare parts price make cost improvements to the existing extended warranty possible.

Download

Unrivalled performance with maximum safety

Fibre cranes overview

High-strength fibre rope for tower cranes

* Rope shortening possible in future, evaluation based on existing crane configuration and its functionality after rope shortening

** Measured on the basis of past service feedback

*** Based on the current price of a fibre rope in the length of the covered rope. Wilful intent, action by third parties and force majeure are not covered