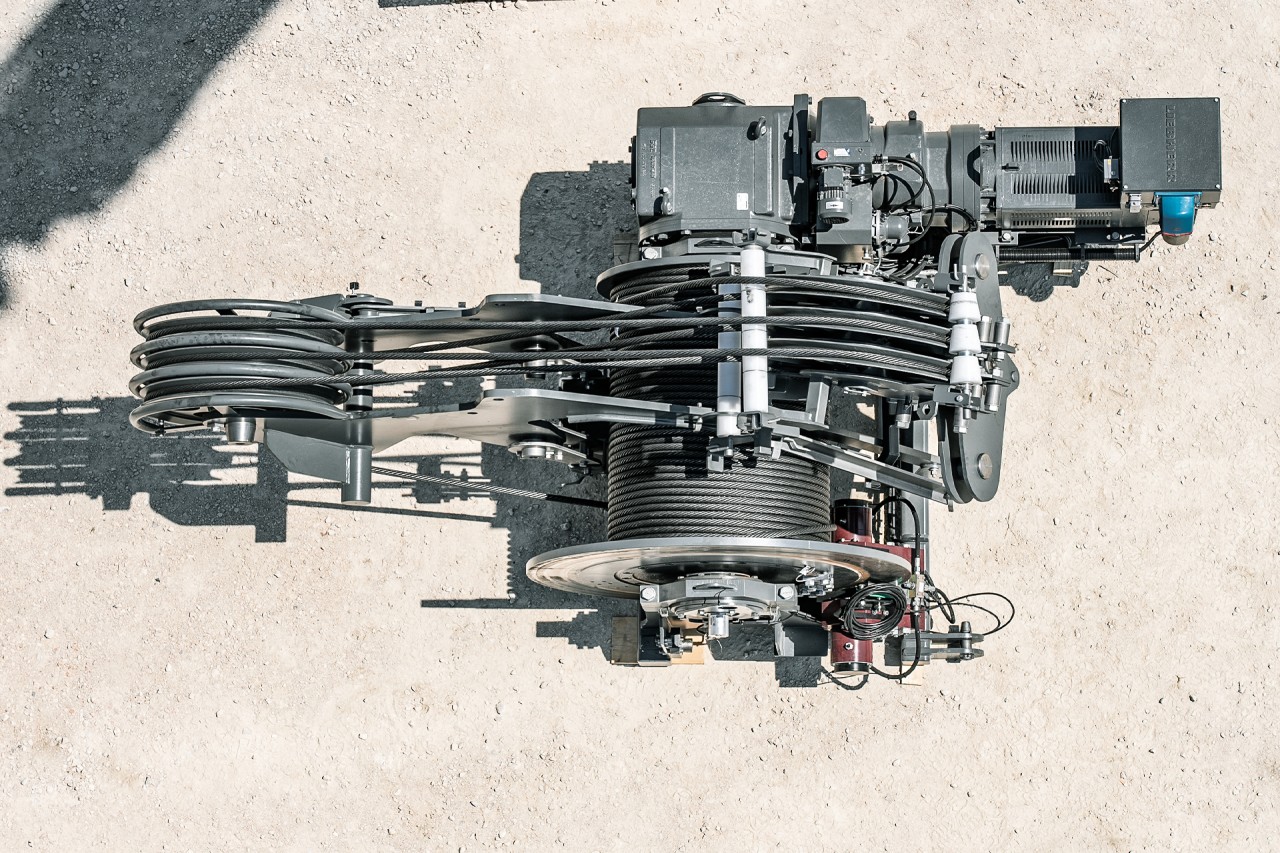

Liebherr’s luffing jib cranes have been specifically developed for use on construction sites where efficiency and maximum flexibility are essential. With their small footprint and powerful Liebherr hoist winches, the luffing jib cranes offer outstanding adaptability to a diverse range of construction site requirements. The luffing jib cranes enable precise and safe load handling in the tightest of spaces.

Advanced technologies such as Load-Plus, Micromove and level luffing give the cranes a clear focus on safety and usability. The reach of the jibs in Liebherr’s luffing jib crane series are flexibly adjustable, and their high lifting capacity makes the cranes an ideal choice for construction companies that value performance as well as quality.

An improved out of service position enables more flexible crane positioning, optimises lifting coverage and increases cost-effective operation by allowing smaller cranes to be used on large construction sites. Positioning several cranes is more efficient, which increases productivity.

The low minimum radius allows loads to be picked up close to the tower, which is an advantage on tight city construction sites. Trucks can also be unloaded closer to the crane, avoiding the need to lift loads over roads. This increases safety, reduces space requirements and enables more flexible crane positioning.

The compact length of the counter-jib allows the cranes to be used in increasingly space-restricted site environments. The collision circle radius can be further reduced with optional steel ballast if required.

The cranes are anchored to the building with tie-ins, providing structural support so that they can grow upwards together with the building. Electronic monitoring and a reduced load chart offer additional safety. The luffing jib cranes in this series can dismantle the tie-ins themselves when climbing down, which further increases efficiency.

HC-L cranes can also be positioned inside buildings, for example in a lift shaft. As construction progresses, the crane (including the tower) is able to climb upwards with the help of a hydraulic power pack and without the need for additional tower sections. The crane is secured in the building by climbing frames, so the crane can be centrally positioned on site.

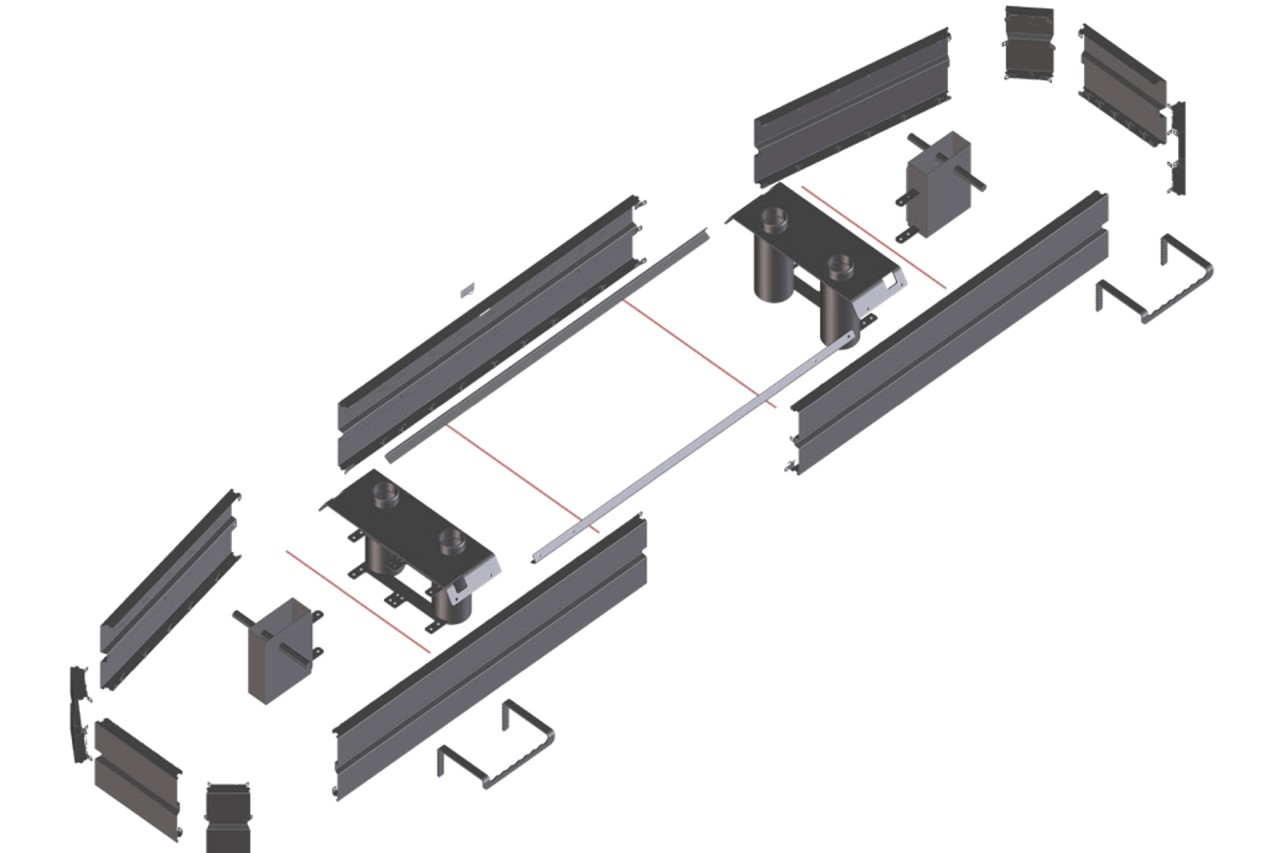

Our tower systems offer the right solution for every challenge. Discover the flexibility each system offers and combine them to maximise lifting capacities. Increasing external dimensions increases the tower’s lifting capacity but also the space required at the tower’s base. Find the right solution for your crane to make your projects a success.

Download

Job reports worldwide

Liebherr luffing jib cranes deliver impressive lifting capacities and lifting speeds. With these features they help ensure fast construction site progress.

Discover our job reports from the most spectacular construction sites around the world, e.g. the completion of the Sagrada Familia in Barcelona, the ‘Four’ megaproject in Frankfurt and the longest suspension bridge in the world, the 1915 Çanakkale Bridge.

Contact us

Sales Partners

Our customers can rely on a global sales network. Look for the contact you need here.