6 minutes | magazine 02/2022

How important is the ground to ensure crane jobs can be completed safely?

As a crane manufacturer, safe crane operations are paramount to us. There is a great deal we can influence, for example the design, production, crane control system with overload warnings and intensive testing. But there are some things we have absolutely no control over. For example, a lack of stability in the ground is one of the most common causes of crane accidents. So we asked the question: Jan-Simon Völk is an expert and technical trainer at our training centre in Ehingen. He explains what you have to look for and which tools and services are helpful for planning crane jobs.

Jan-Simon Völk - Technical Trainer

The ground is the foundation for the crane. If it does not provide sufficient load-bearing capacity, there is no way that the crane can operate properly and be stable. In fact, the ground beneath its feet will simply fall in. So there are two major questions that require answering: What is the load bearing capacity of the ground and to what forces will it be subjected during the job?

Firstly on the question of load bearing capacity, we always talk about the maximum ground pressure in kN/m². Let me give you a few examples: Ground consisting of sand, gravel, stone and mixtures of them can take a ground pressure of around 200 kN/m², which corresponds to around 20 tonnes per square metre. Clay-type soils have lower load bearing capacity. On the other hand, solid soil types with mixed grain sizes have higher values, up to around 300 kN/m². Rocky ground is perfect. It can withstand loads of over 1,500 kN/m². If you have any doubt about the load bearing capacity of the ground, you must commission a study by an expert.

The question of the ground is a fundamental one. Build on our support and use our tools.

The operating manual

Let’s now look at the force that the crane places on the ground. The fastest information is provided by the operating manual for the crane. It provides the maximum support force. Let’s look at a medium-sized crane as an example: The maximum support force of the LTM 1230-5.1 is 1,109 kN. The standard support plates measures 0.6 x 0.6 metres, in other words 0.36 m². We reduce this area by 20 percent because the outer edge has no load bearing capacity due to its having rounded edges. So the load bearing capacity of the ground must be 3,851 kN/m² (1,109kN/0.288m²). As the ground on sites rarely provides these values, the only solution is to increase the support area. For example if we use support timber with an area of 1 m², we require a load bearing capacity of 1,109 kN/m². Vice versa, with a load bearing capacity of 300 kN/m², base plates measuring 3.7 m² would be required (1,109 kN/ 300 kN/m²).

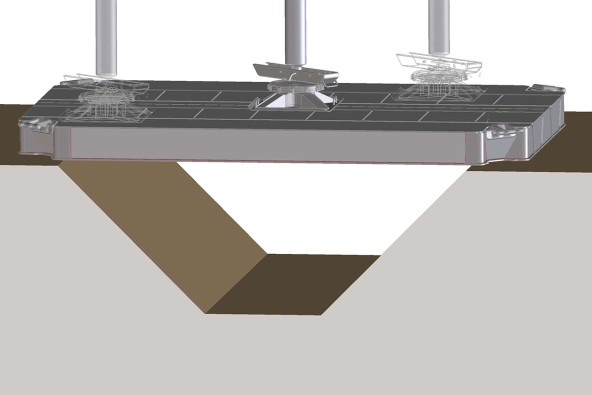

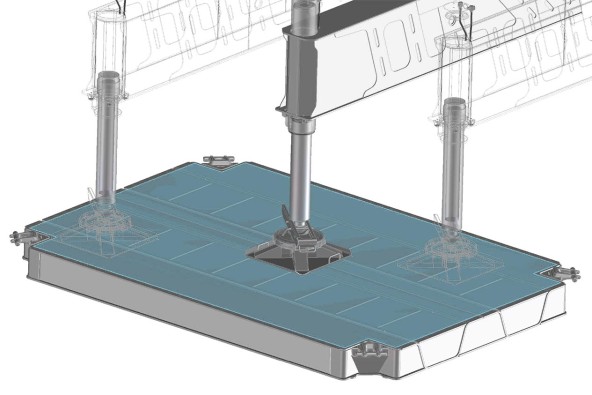

Force transfer - Our new base plates make eccentric support possible and they deliver maximum load bearing capacity even when positioned over cavities.

Job planning tools

So now let me give you an important tip. On a specific job, it is possible that the maximum support force will not be reached. In this case, the LICCON job planner or Crane Planner 2.0 can help as these tools deliver the precise support force. If, for example, it is 700 kN, base plates measuring 2.33 m² would suffice (700 kN/ 300 kN/m²). That saves handling work and costs.

VarioBase®

There are often areas on construction sites were it is simply not possible to support a crane, for example over sewage pipes or other cavities in the ground. This is where our VarioBase® variable supporting base comes into its own. Each individual outrigger can be extended to any length and the hoist can then be carried out safely using the load moment limitation of the LICCON control system. Plan the job using one of the job planning tools so that you also calculate the precise support forces involved with VarioBase®. What is more, you can actually simulate the job before carrying out the hoist on site using the LICCON2 control system – you can never be too safe.

New Liebherr steel outrigger pads

We have developed a new generation of steel outrigger pads for mobile cranes which deliver a whole host of benefits. They can be loaded over the full area and can be positioned over cavities – and still deliver maximum load bearing capacity. What is more, they are also designed for simple transport as they are easy to handle and have a maximum width of 2.4 metres. Their centring system also means that they can be stacked safely.

Professional training courses and ECOL mobile crane operators licence

We provide professional training courses for practical subjects both at Ehingen and at other training centres all over the world to extend your expertise and ensure safe mobile and crawler crane operations. Despite all the technology, we must not forget about the person operating it. We all bear a great deal of responsibility, both manufacturers and contractors.

Liebherr was the very first company in Germany to offer training to acquire the new ECOL European mobile crane licence (European Crane Operators Licence) and these courses have been available since 2020. Safety is absolutely paramount. We want to avoid damage and in particular personal injuries. Not only does that require safe cranes, but also good training for crane operators. An internationally accepted crane operators licence will increase the safety of crane operations and enable our customers and crane operators to extend their activities internationally without different licences, and in some cases even beyond the borders of the EU.

Professional training is extremely important as ultimately the crane operator has the last word. He bears ultimate responsibility and decides whether he can carry out the hoist on the ground at the site or not.

You can find out more about our new steel outrigger pads here: A stable base on every site.

This article was published in the UpLoad magazine 02 | 2022.