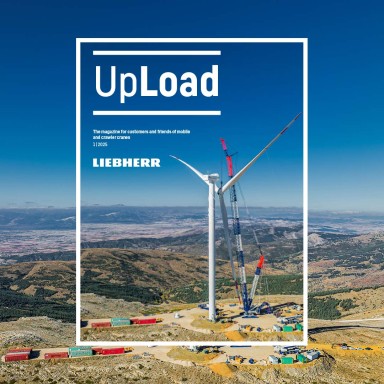

6 minutes - magazine 01 | 2025

Streamlined, strong, aiming high

Our second LICCON3 crane, the LTM 1100-5.3, has been proving its worth in practice for several months now. We are delighted with the positive response from our partners and customers, which once again confirms that we are on the right track by offering modern mobile cranes with customised handling, attractive design and, above all, high functionality.

Our new LTM 1100-5.3 gets to work!

As a highlight, this 5-axle mobile crane, the only one in the world with a width of just 2.55 metres, has a 62-metre boom on board in addition to the proven top features such as VarioBase® and VarioBallast®. It can also travel with an axle load of just nine tonnes or carry up to 16.9 tonnes of ballast. In Belgium and the Netherlands, we visited two of our new 100-tonne cranes on typical assignments.

“Only 2.55 metres wide is often quite practical.” – Steve Van Belle in his new Liebherr crane. The position of the new touchscreen is clearly visible.

The first stop is Harelbeke, a small town in the west of Belgium, close to the French border. Early in the morning, the LTM 1100-5.3 from the crane company Desutter arrives at the still fallow construction site. Its mission: the assembly of a 30-metre-high Liebherr tower crane. A classic urban construction site with little space for the crane and hardly any room for the incoming transport vehicles. But Steve Van Belle, driver of the red mobile crane, has his vehicle in position in no time at all and extends the support beams and cylinders by remote control. The ballast blocks are placed and bolted from the driver’s cab. Finally, he has to telescope out the boom 40 metres and is ready for the lift a good half hour after his arrival with his machine.

Heaviest load case: The LTM 1100-5.3 may be an all-rounder, but with its 62-metre telescopic boom it is also predestined for erecting construction cranes. A gross load of over eight tonnes hangs from the hook with the slewing ring at a height of 30 metres.

Change of location now to Almere in the Netherlands, a good 200 kilometres away. Greater Amsterdam area. Rogiër Leurink has already travelled a long way this morning in his LTM 1100-5.3. It is around 130 kilometres by motorway from Elsendorp, the main location of Haegens Kraanverhuur. “Our crane and heavy haulage company has taken delivery of the first of the new 100-tonne cranes in the Netherlands,” says Rogiër. “In this small development of around 20 new tiny houses, we are to erect the last of the two-part buildings today.” The lifting height is not an issue for the crane and driver. As the last house is being erected in the furthest corner of the housing estate, outreach is required.

Although Rogiër first has to drive his vehicle a long way backwards on a lane of metal plates to the assembly site, after around 40 minutes he has also set up his crane and is ready for the first lift. The mobile crane has also brought the ballast of over 15 tonnes that it needs for this job with it on the road – there is no need for separate transport. Setting up the tiny house is child’s play. With a radius of 15 metres, the crane places the ground floor, which weighs over twelve tonnes, and then places the roof module on top. Building a house in three hours. The owner is already ready with her furniture.

“A fantastic machine.” – Rogiër Leurink drives the new LTM 1100-5.3 for Haegens Kraanverhuur. The company operates over 40 mobile, loader and crawler cranes in Elsendorp and Roermond.

How does he like his crane? Rogiër is full of praise. Although: he would like to reduce the amount of information shown on the smart display in the cab. “Otherwise, the operation of the LTM 1100-5.3 is clear and very simple. One major difference to the previous Liebherr mobile cranes is the lower driver’s cab. It’s a real luxury cabin,” he enthuses. “I simply really enjoy driving on the road. Super insulated, very quiet and the new gearbox shifts perfectly. A fantastic machine.”

Back to Belgium. In Harelbeke, Steve Van Belle still has to install the upper sections of the tower crane. The 30 metre high tower is already in place and the slewing ring is currently being installed. The crane precisely delivers the eight-tonne component to the fitters at the top. Finally, the lattice sections of the boom and a few ballast blocks – then Steve can also dismantle his LTM and drive back to the company headquarters in Harelbeke. Desutter has stationed over 30 Liebherr mobile cranes there and in the harbour of Ghent.

Only 2.55 metres wide

For Steve, one of the main advantages of his new crane is the large amount of ballast it can carry. “I have 15.4 tonnes with me. Thanks to the possibilities of VarioBallast®, this is almost always enough. I’ve been operating the crane for three months now and have only had to work with a full ballast twice.” He sees the compact design as another plus point: “With a width of just 2.55 metres, I can also manage well on narrow factory sites, roundabouts or narrow country lanes.” But there is one more thing Steve wants to get rid of before he leaves the construction site with his mobile crane: “There is one problem: The crane travels so smoothly and comfortably that you quickly exceed the permitted speed.”

This article was published in the UpLoad magazine 01 | 2025.