Technical spotlight: Operator Assistance Systems for mining dozers

Liebherr’s range of dozers are powerful pushing machines. To help our customers release their full potential, we developed a suite of Operator Assistance Systems to unlock even greater fuel efficiency and productivity while reducing operator fatigue. But how? Let’s take a look!

The Liebherr Group introduced Operator Assistance Systems (OAS) for its latest generation – Generation 8 – of small to mid-sized dozers in 2019. Since then, these systems have been enhancing productivity, improving fuel efficiency and reducing operator fatigue on work sites all over the world. And with the 2024 launch of the PR 776 G8 – the next generation of our flagship mining dozer – customers seeking a 70 t dozing solution could also experience the powerful combination of Liebherr dozers and OAS.

So what do these systems actually do? Well, it depends on which package you’re talking about. Liebherr’s range of OAS includes two tailored packages: one for blade control and another for ripper control. The Blade Control Assistance package provides operators with positional awareness and assistance with blade movement, while the Ripper Control Assistance package reduces operator workload by automating repetitive tasks.

A closer look at the Blade Control Assistance package

There are five OAS within the Blade Control Assistance package, each handling a different aspect of precision blade control. These are:

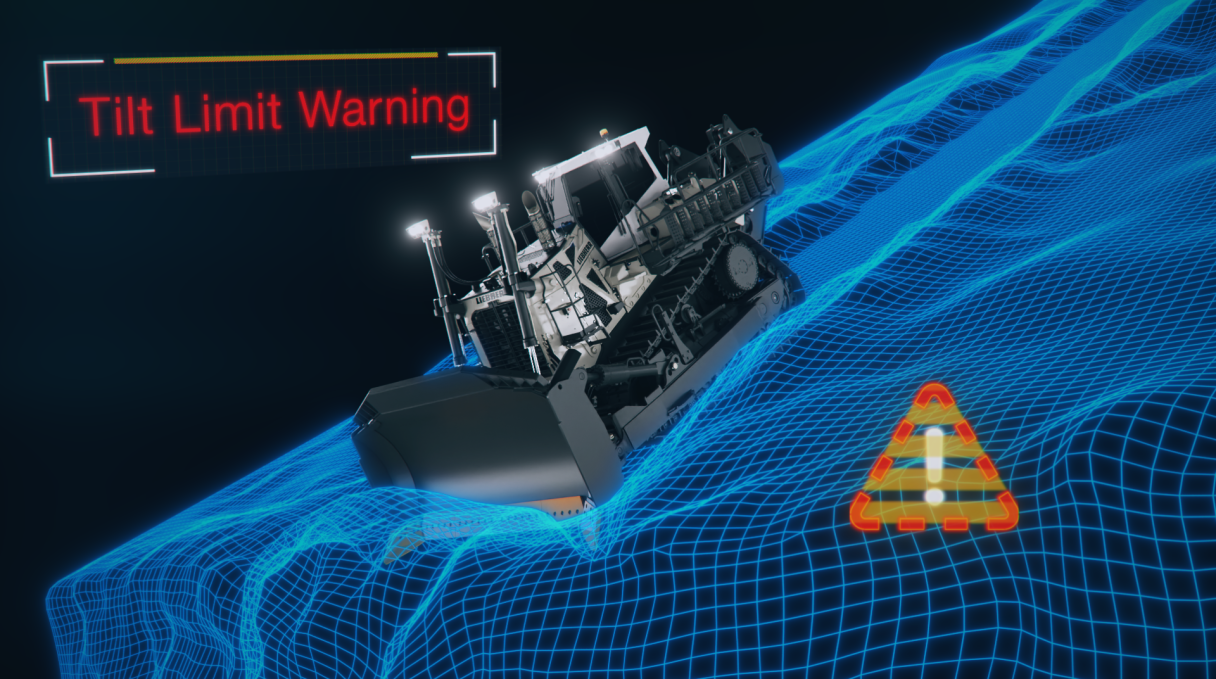

— Indicate: displays the exact inclination of both the blade and the dozer in longitudinal and lateral directions.

— Free Grade: keeps the blade stable, in longitudinal and lateral directions, when pushing material or levelling flat surfaces, ramps or embankments.

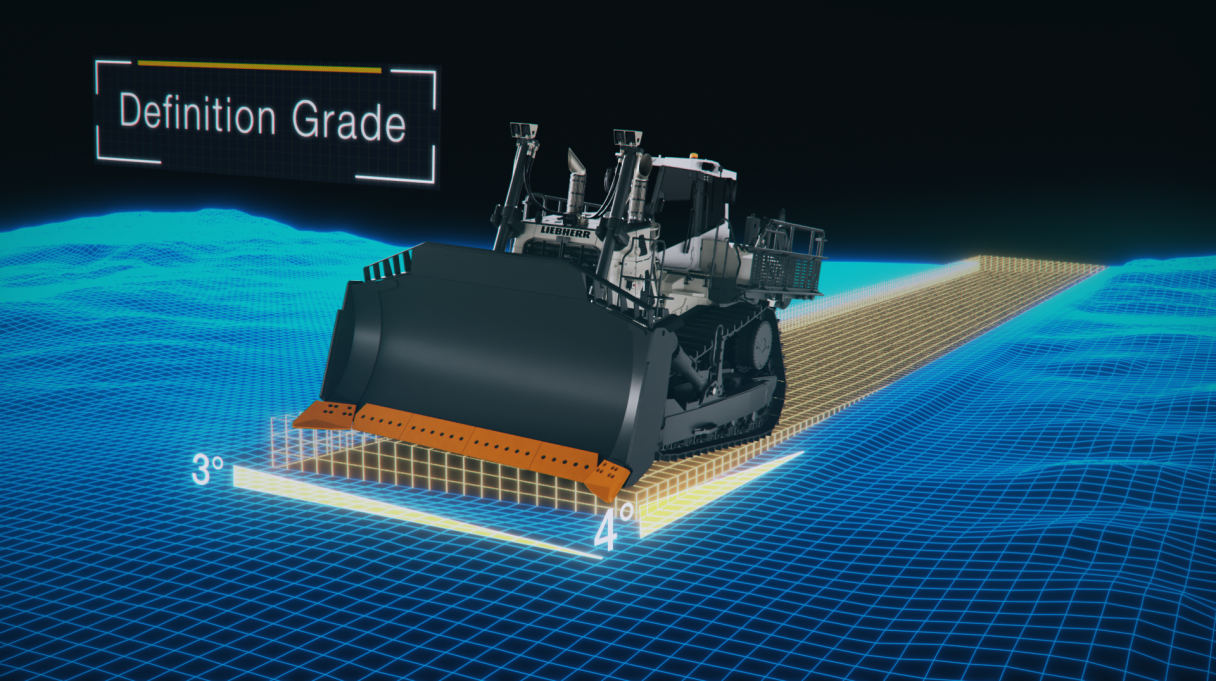

— Definition Grade: actively, and automatically, controls the blade to keep it at a pre-determined angle for modelling basic 2D surfaces.

— Auto-Blade-Lift and Auto-Blade-Return: automatically lifts the blade while reversing and lowers it when travelling forwards.

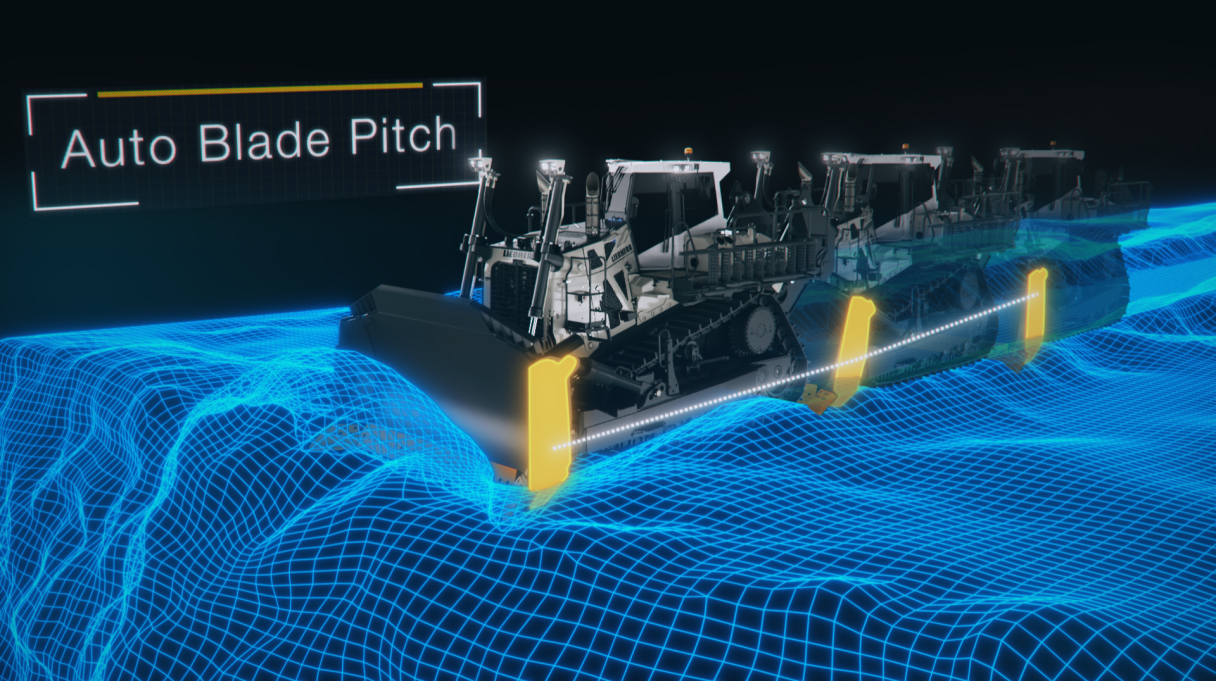

— Auto-Blade-Pitch: saves and stores three different cutting angles so the blade can automatically be set to the right positions during the load, carry and dump work phases of a push cycle.

The power behind the scenes

Even though these packages control opposing ends of the dozer, they both depend on the same core technologies. The foundation upon which each OAS is built is the electronic machine architecture of our Generation 8 dozers. This architecture underpins the electronic pivot control that gives the OAS their mastery over the blade and ripper. Smart technology detects the dozer’s position, speed, specific force and angular rate and feed this information back into the OAS, so they always have an accurate representation of the dozer on site. This technology also makes it possible for these systems to operate entirely without additional stationary equipment or GNSS/GPS signals to ensure consistent and reliable performance in any environment, setting these solutions apart from other OEM offerings.

Blade Control Assistance package

This comprehensive package includes a range of OAS that offers precision control over the blade with minimal manual input, which increases pushing performance and operating accuracy while lessening operator fatigue. Each system uses the data collected by a variety of sensors to understand the position and inclination of both the dozer and the blade in relation to their surroundings. Operators can view this information on the main touchscreen display in the cab, along with all other vital machine data. The systems also use the information gleaned from these sensors to keep the blade stable, save preferred blade positions for levelling and automatically lift and lower the blade when needed. Operators can amend the blade’s position with just a few taps on the touchscreen or by using the joysticks in the cab and their buttons.

A closer look at the Ripper Control Assistance package

There are two OAs in this package, and each automates a different ripper task. These are:

Auto-Lift and Auto-Stow: automatically lifts and fully retracts the ripper.

Auto-Lower: saves and stores two ripper positions – a cutting angle position for cutting into the first layer of ground material and a working position for penetrating ground material.

Ripper Control Assistance package

In this package, the data collected by a range of sensors is used in conjunction with the joystick in the cab to automate repetitive ripper tasks like lifting, retracting and moving into working and cutting positions. Automating these tasks helps to reduce operators’ mental workload which in turn helps to keep stress and fatigue to a minimum.

Operators can save their preferred ripping positions within the system and then use the joystick controls to move the ripper as needed. Pressing the buttons on the joystick sends different electrical signals to the ripper’s hydraulic control valve, depending on the number of times the joystick button is pressed and which system is active at the time. A single press can either raise the ripper or move it to the first of two saved positions. On the other hand, a double press can retract the ripper or move it to the second of two saved positions.

Availability and retrofitability

All of our OAS are available for the latest generation of our PR 776 mining dozer, the PR 776 G8, and can be installed at first fit or retrofitted onto machines already in operation. Other dozers in the Generation 8 range, up to the 40 t class, have Free Grade and Definition Grade OAS installed at first fit.

A peek into the future

In 2026 we’ll be introducing a new Load Control package that builds upon the existing Blade Control Assistance and Ripper Control Assistance packages for our PR 776 G8 mining dozer. This upcoming package includes two advanced, non-GNSS-dependent assistance features – Blade Load Control and Ripper Load Control – engineered to enhance pushing and ripping efficiency. These systems will monitor real-time machine load, blade and ripper pitch and ground interaction while integrated control algorithms will process this data to automatically adjust the blade or ripper position for optimal material engagement. The Load Control package will maximise traction, reduce track slip and support consistent performance across varying ground conditions – all while reducing operator workload.