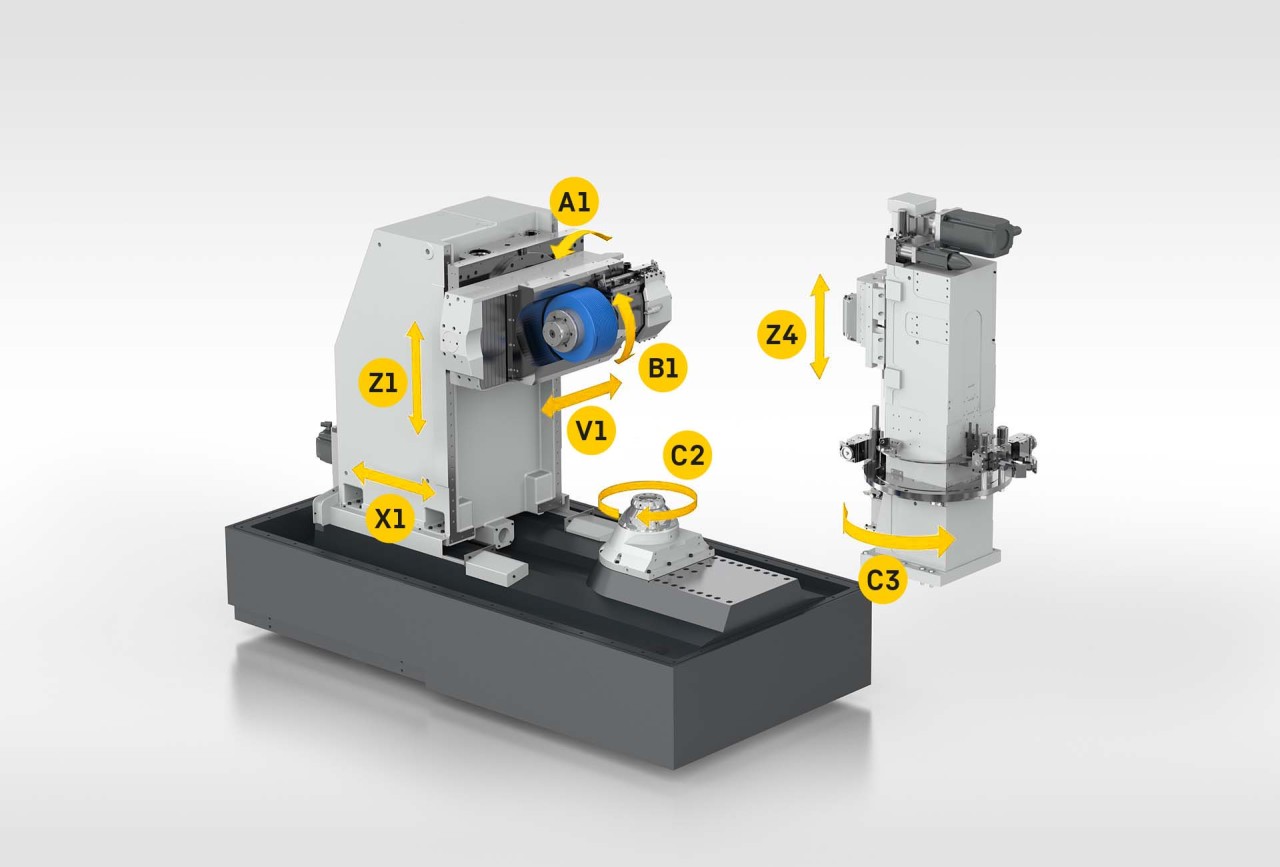

LGG 180 - 280 / 400 M

A passion for surfaces.

Highlights

Machine length - 3,000 mm

3,000 mm

Machine width - 2,200 mm

2,200 mm

Machine height - 3,000 mm

3,000 mm

Workpiece diameter - 180 - 400 mm

180 - 400 mm

Axial travel - 660 mm

660 mm

Shift distance - 230 - 270 mm

230 - 270 mm

Min. position above table - 90 mm

90 mm

Grinding head swivel angle - 45 °

45 °

Workpiece speed - 3,000 min-1

3,000 min-1

Reliable

Short grinding times

Consistently high quality

Features

- High quality and reliability across the entire series

- Fast loading thanks to an integrated ringloader

- Chip-to-chip times

- Gears: As little as 4 seconds

- Shafts: As little as 6.5 seconds

- Small space requirement

- Easy to maintain

External and internal grinding heads

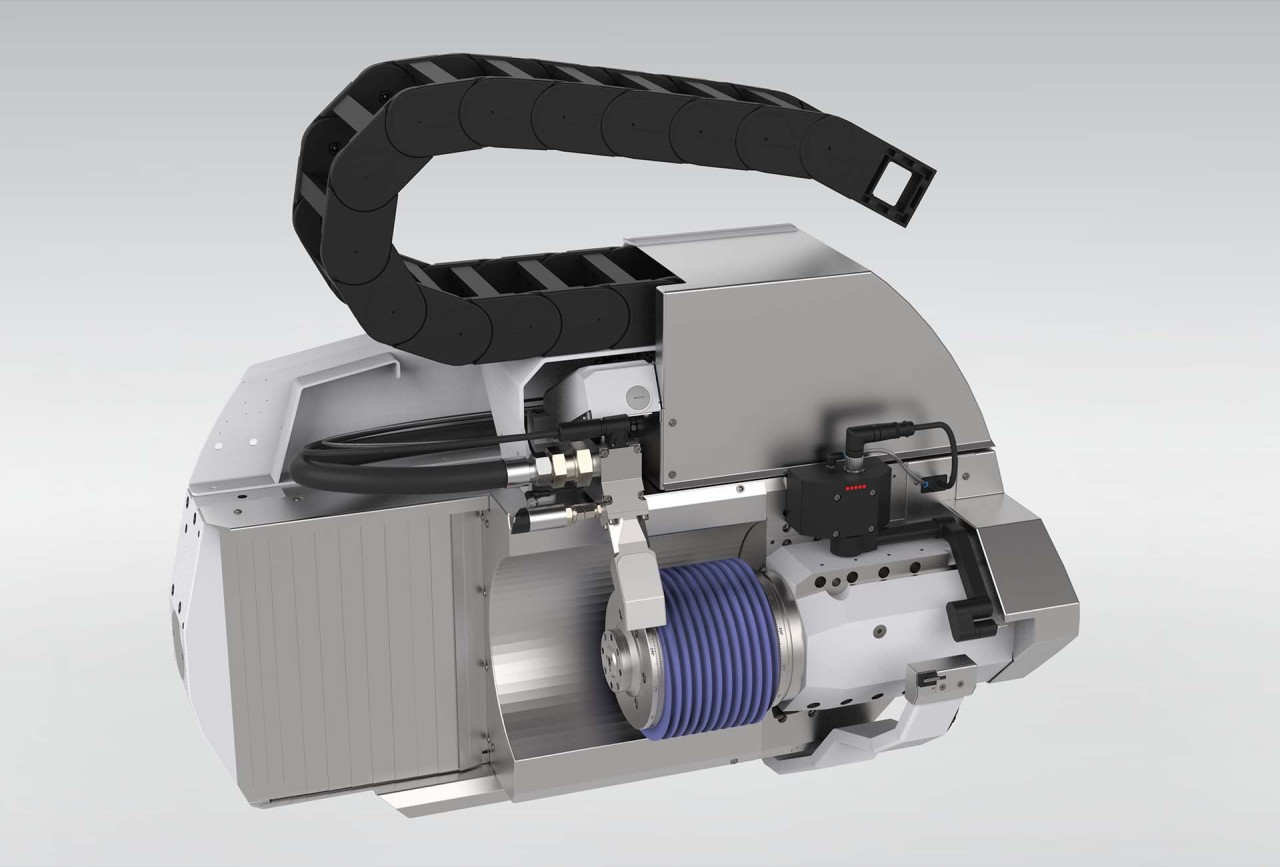

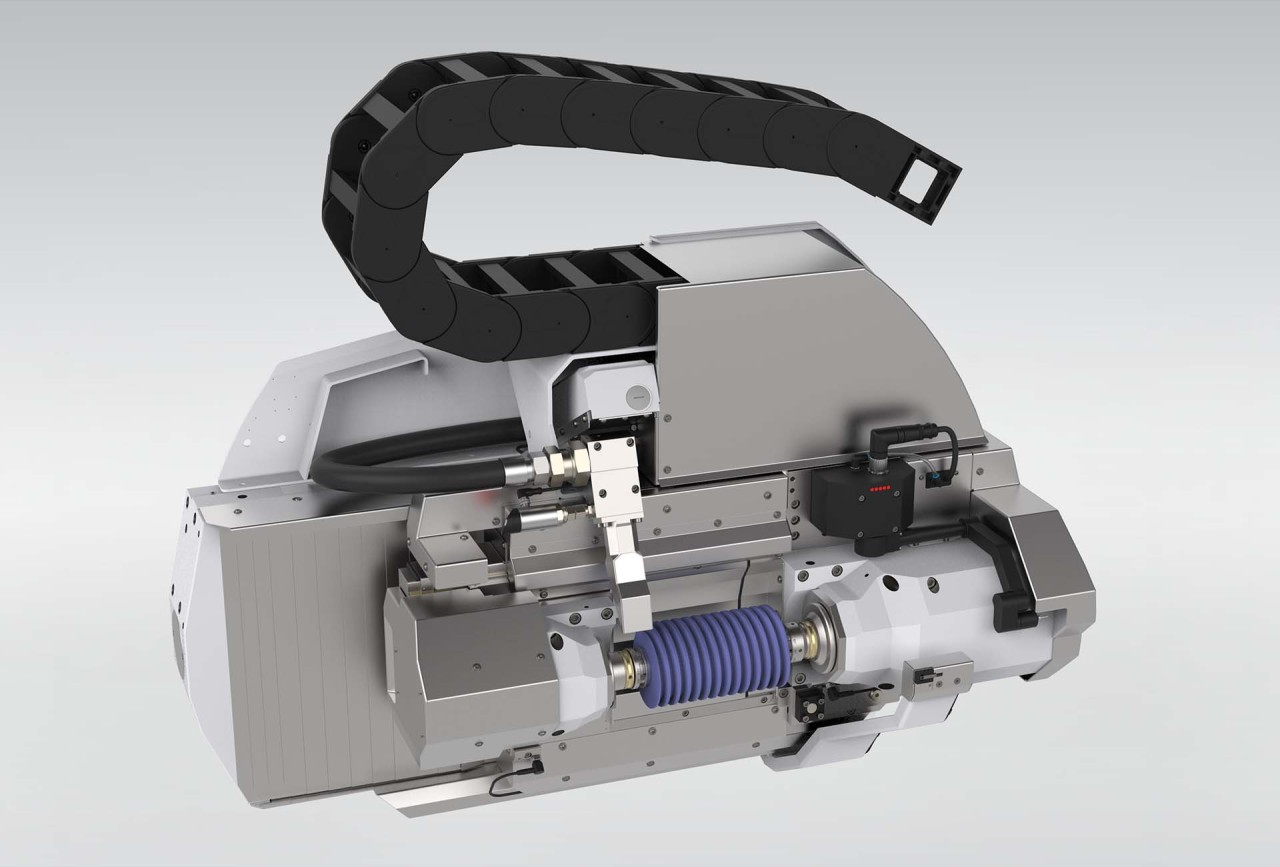

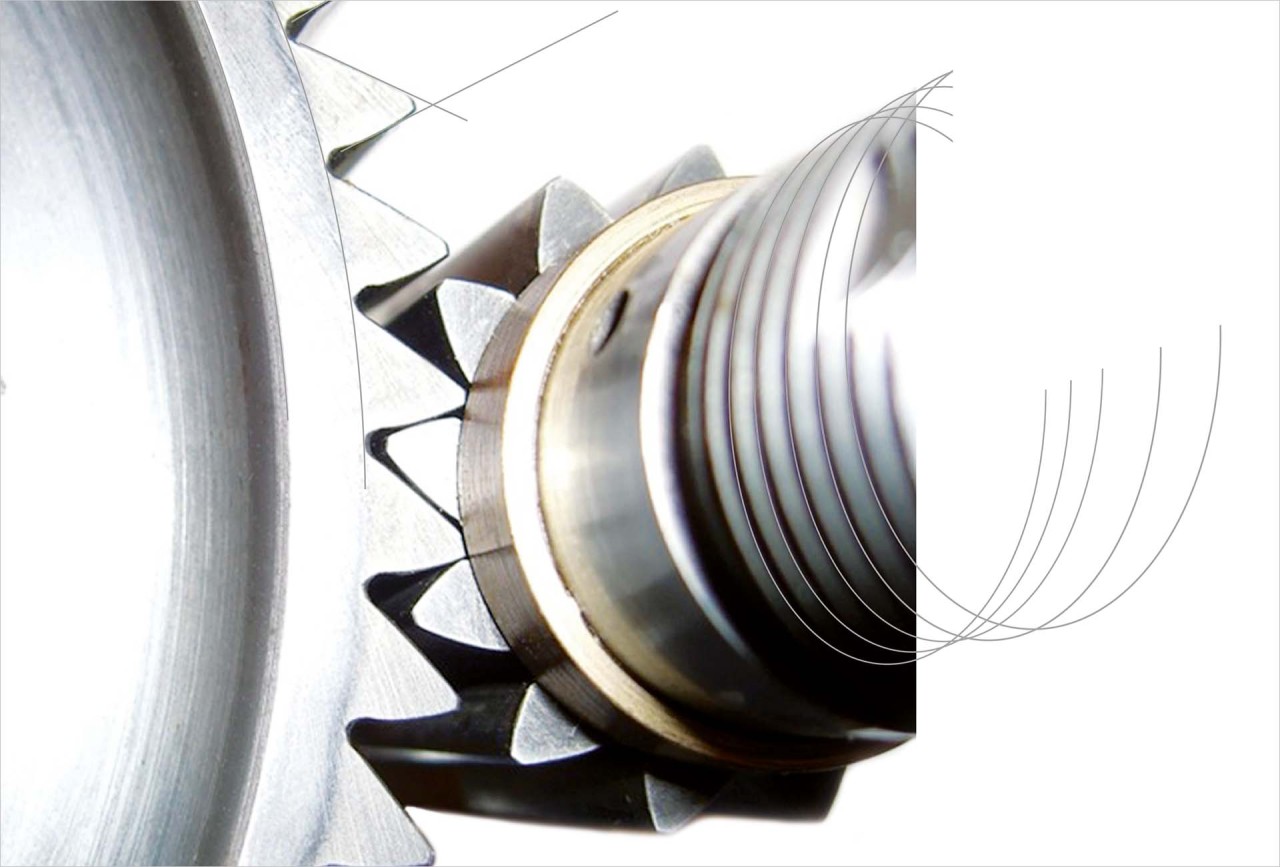

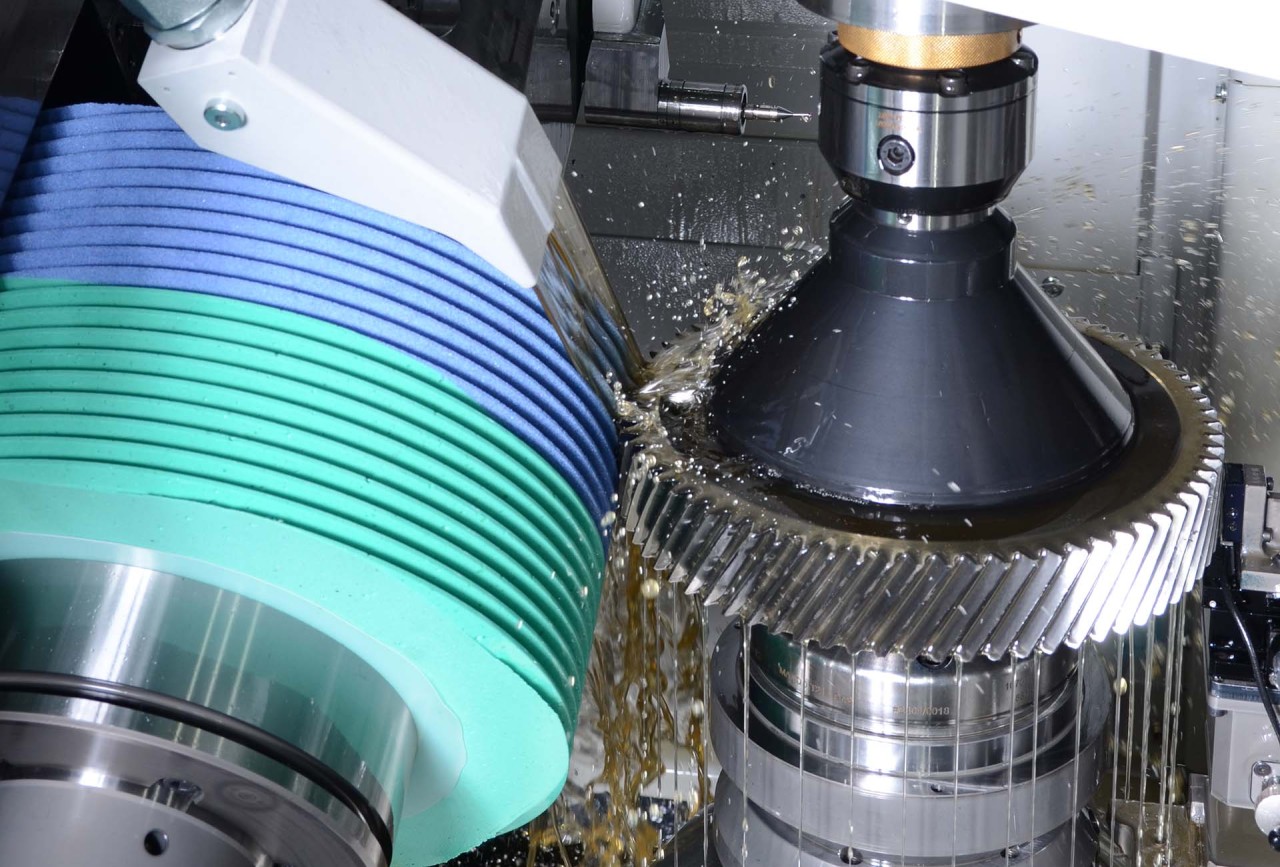

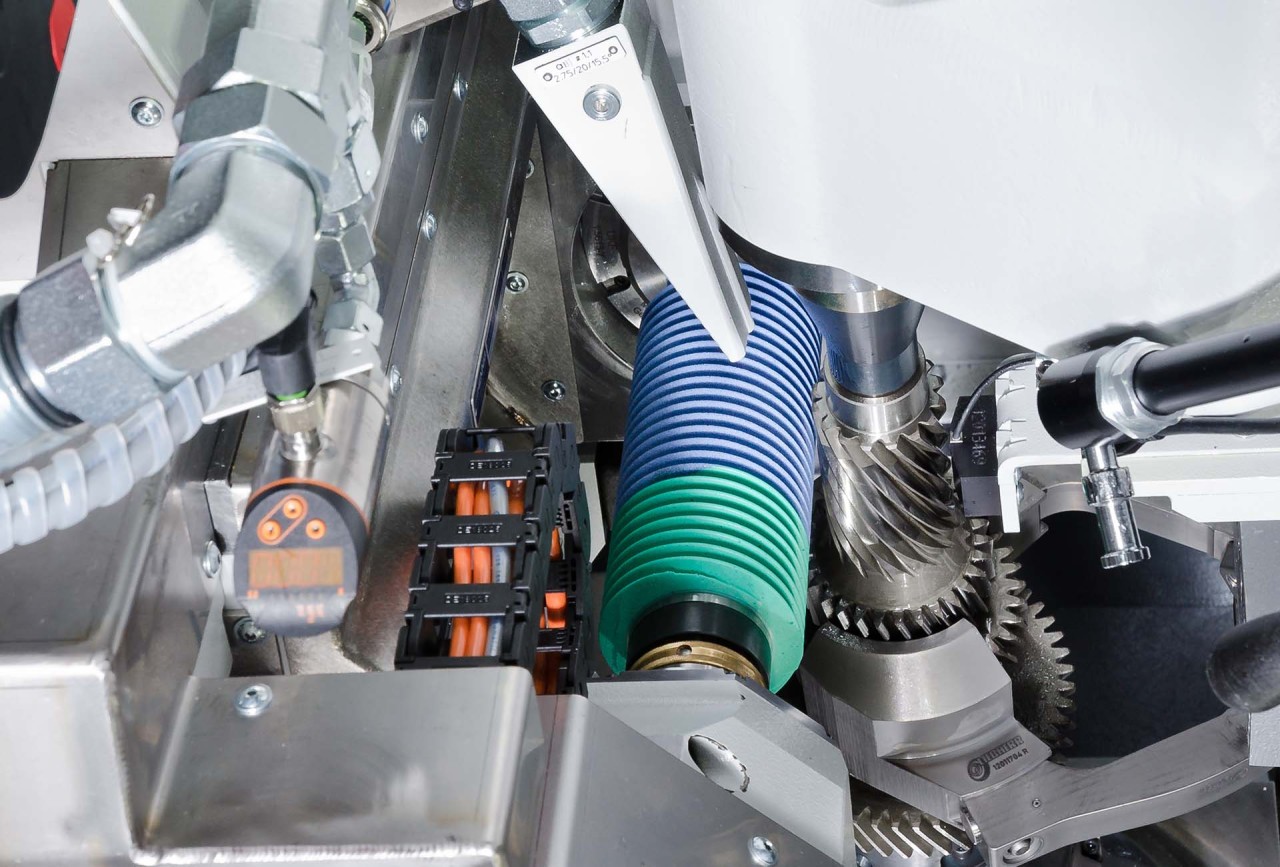

The LGG machines are perfect for generating grinding and profile grinding. As standard, the machines are equipped with an external grinding head and can be supplemented with an internal grinding head.

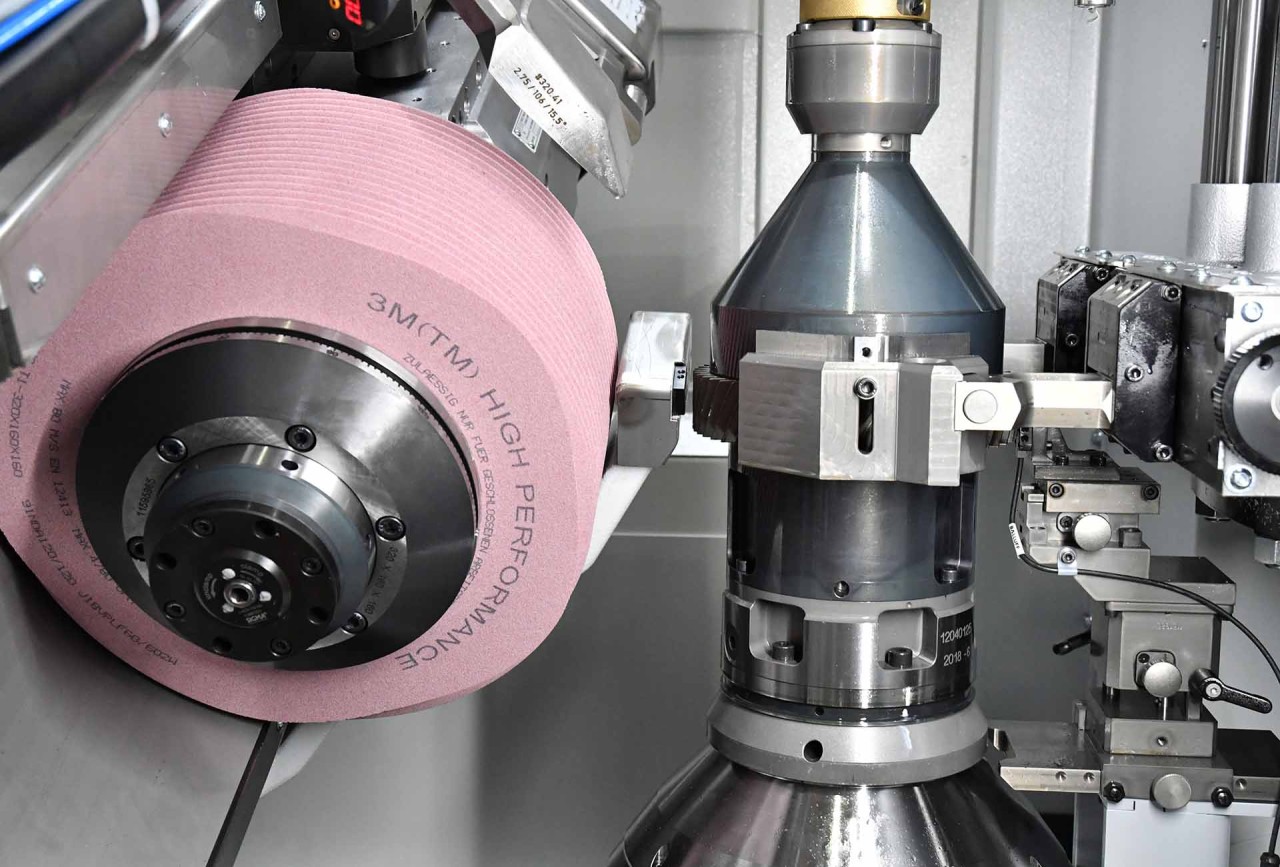

In both external grinding heads, the balancing systems are integrated in the spindle. High drive power and speeds offer big advantages for example, when using new grinding material. Simple and fast replacement of the grinding arbor is made possible by the use of modern tool holding. For collision-critical workpieces and for special tooth corrections, small grinding tool diameters are available.

Fast and easy changeover

The adaptable internal grinding arm can be mounted quickly and easily on the external grinding head and are driven using the main drive. Other grinding arms can be provided on request.

In only 30minutes from external to internal grinding

Video

Gear manufacturing for aerospace

Technology

Innovation

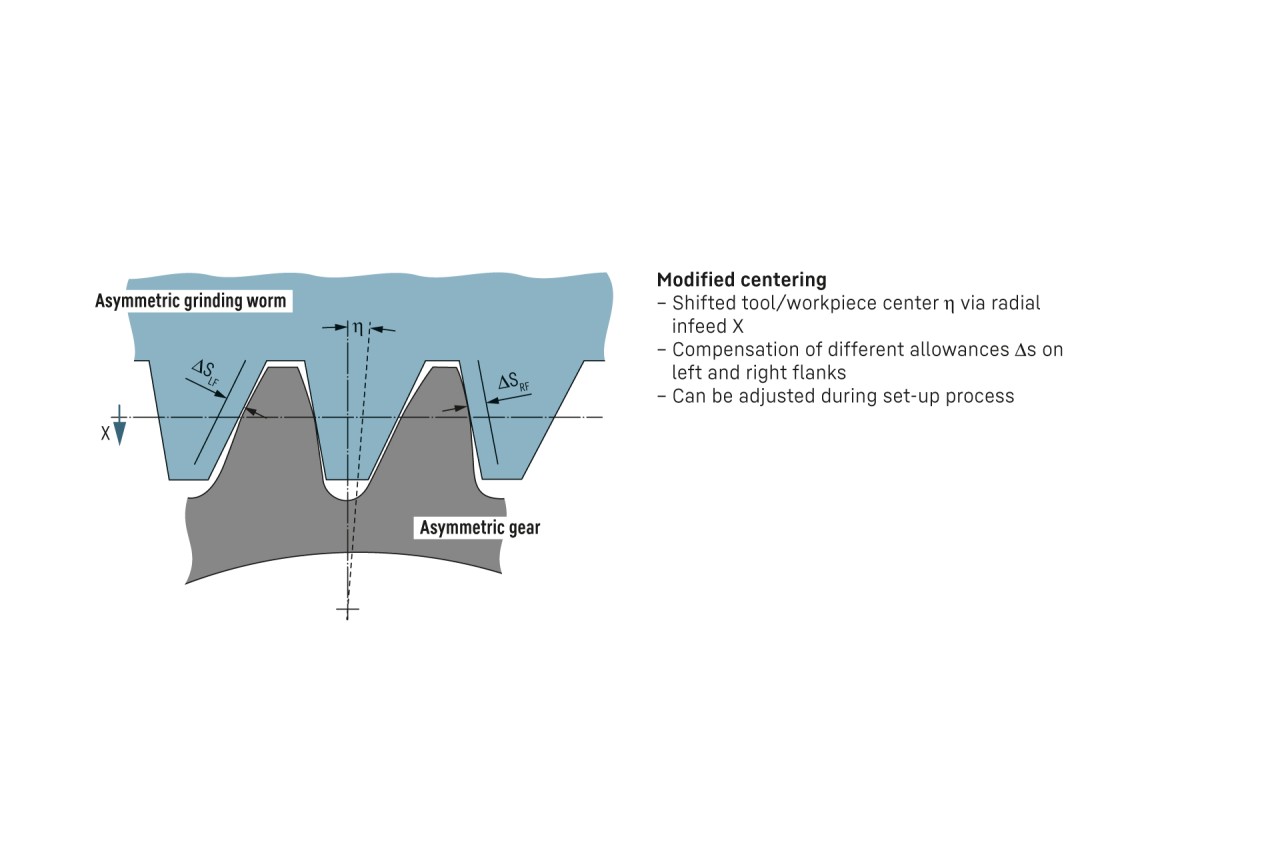

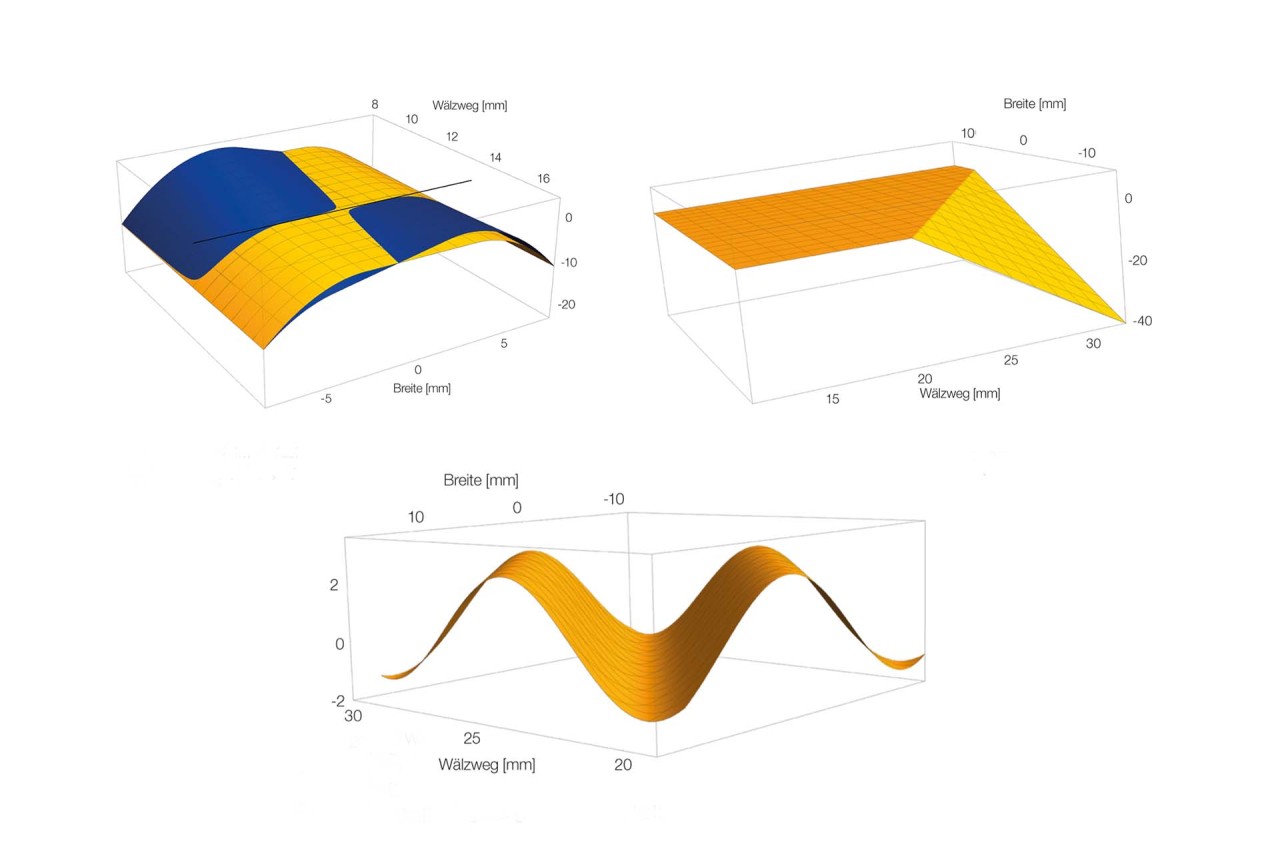

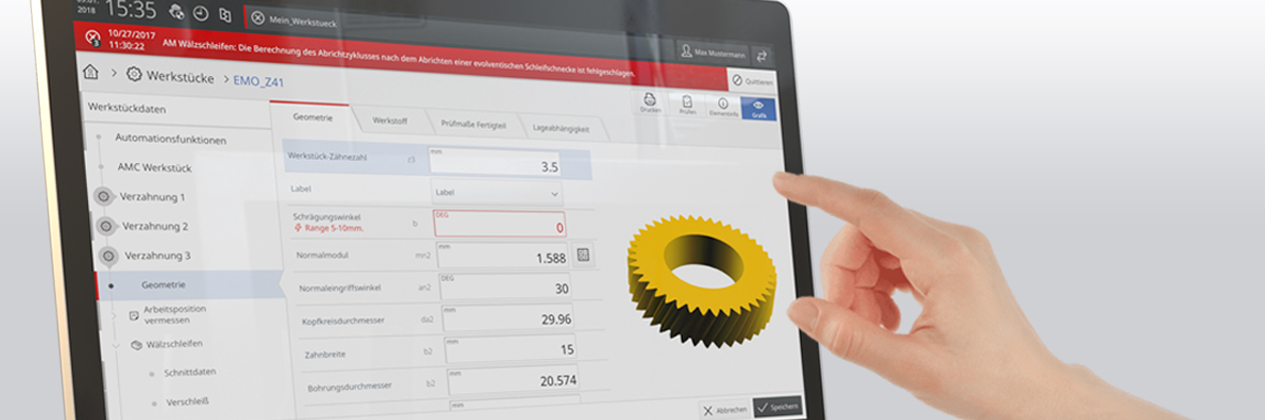

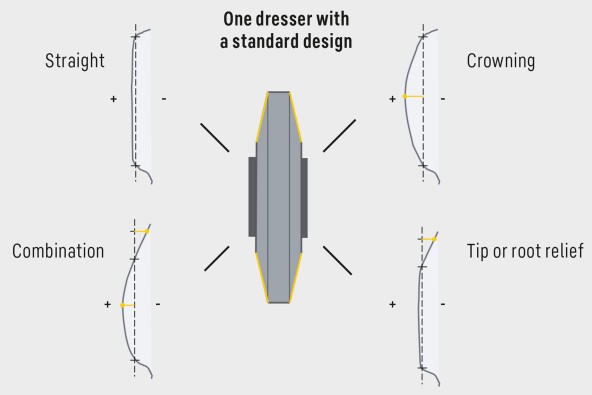

DIP – Dresser independent profile modifications

DIP is a versatile generating grinding method specially developed by Liebherr that uses dressable grinding worms. It allows profile modification on the workpiece when using profile rolls in the dressing process. In particular, profile angle modifications, crowning, as well as tip and root reliefs can be precisely specified and ground. It offers the advantage that using profile rolls makes the dressing process many times faster, and the surface of the worm is the same as for typical series production.

Generating grinding with small tools

Finishing grinding or polishing

Generating or profile grinding with dressing-free CBN

Integrated centrifugal device

Automation

Easy to operate

Technical data

| Machine length | 3,000 mm |

| Machine width | 2,200 mm |

| Machine height | 3,000 mm |

| Axial travel | 660 mm |

| Min. position above table | 90 mm |

| Grinding head swivel angle | 45 ° |

| Workpiece speed | 3,000 min-1 |

Variants

| Variants | LGG 180 | LGG 280 | LGG 400 M |

|---|---|---|---|

| Workpiece diameter (mm) | 180 | 280 | 400 |