5 minutes reading time

Sustainable metal recovery using wound CFRP magnetic rotors

Together with IMRO, we are demonstrating how fiber composite technology in non-ferrous metal separators (NF separators) enables maximum precision and sustainable metal recovery. Our carbon fiber-wrapped magnetic rotors ensure smooth rotation, maximum separation efficiency and longer service life - and thus contribute to more efficient, resource-saving recycling processes.

About IMRO

IMRO Maschinenbau develops and manufactures machines and systems as well as the latest recycling processes with a focus on separation technology. The solutions are individually tailored to the requirements of the companies and enable efficient and sustainable recycling concepts.

Industry

Machine

Liebherr product

Starting Point

Successful recovery of valuable resources

Numerous waste products, production scrap, and other material flows contain valuable non‑ferrous metals like aluminum or copper. To reclaim these, highly specialised separation equipment is used. At the heart of the process is the NF separator: it applies eddy current technology to precisely separate non‑ferrous metals from mixed material streams and make them usable again.

Challenge

High speeds, extreme forces – a demanding rotor environment

In the NF separator, a fast‑spinning magnetic rotor produces the necessary pole‑change frequency. The pole changes and the resulting eddy currents in the non‑ferrous metals generate a repelling force that propels the particles out of the material flow. At speeds of up to 3,800 rpm, massive centrifugal forces act on the magnets and the structure. Traditional stainless‑steel housings tend to deform (become oval), causing imbalance, unstable machine performance, higher wear, and the need to replace bearings early. For modern recycling systems, this is neither efficient nor cost‑effective over time.

Solution

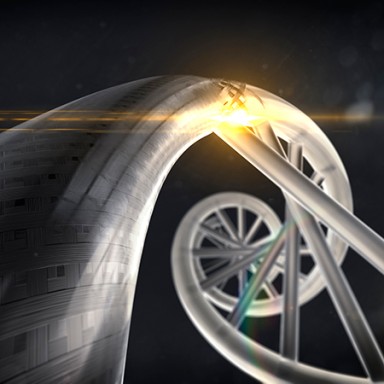

CFRP rotor winding: stable, precise, magnetically compatible

Our specially wound CFRP wrap surrounds the magnetic rotors, keeping the magnets safely in place even at the highest speeds. Carbon‑fiber reinforced plastic provides high strength with minimal deformation at thin wall thickness and does not interfere with the magnetic fields. The outcome is a perfectly round, lightweight, and long‑lasting rotor housing that delivers consistent, low‑vibration performance.

Application

More precision in IMRO’s eddy current separator

The CFRP‑wound magnetic rotor is employed in IMRO’s NF separators. With its stable rotor geometry, the gap to the outer fiberglass housing can be kept smaller – boosting the magnetic effect on the material. This allows for even more precise separation of the tiniest non‑ferrous metals and sustainably enhances the recycling yield.