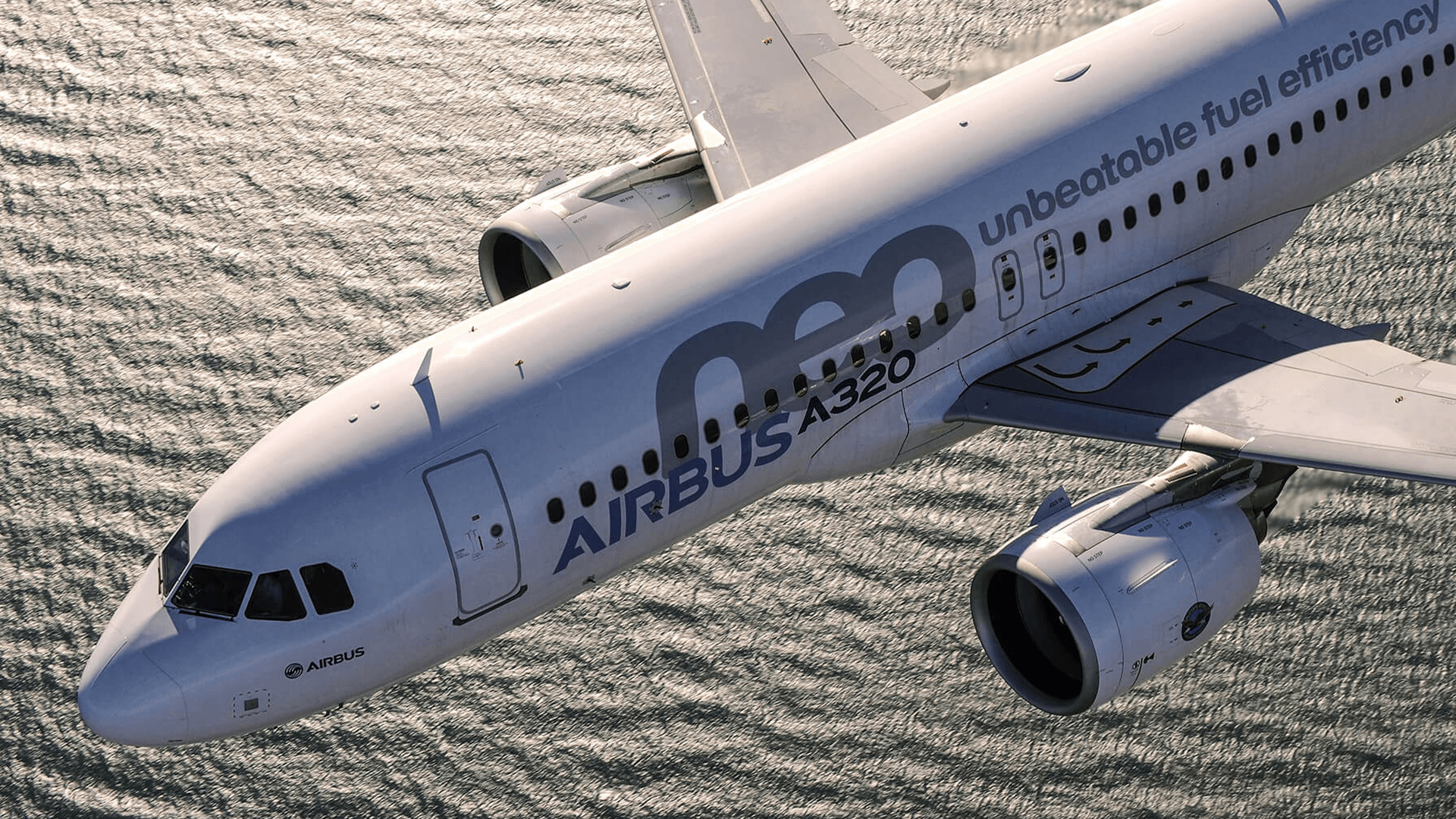

Liebherr brings over many decades of expertise in designing and manufacturing on-board electronics for controlling and monitoring highly integrated, flight-critical systems. With tens of thousands of units in service across commercial, defense, and business aircraft, Liebherr’s electronics are trusted for their outstanding reliability and performance in key ATA chapters.

Benefits of partnering with Liebherr

Extensive in-house know-how

Integrated solutions

Diverse product portfolio

On-board electronics from nose to tail

Liebherr delivers advanced electronics for powering and controlling critical aircraft functions. From high-performance actuators and compressors to flight-critical signal electronics, static inverters, and adaptable remote electronic units, these technologies ensure safety, reliability, and efficiency across many aerospace applications.

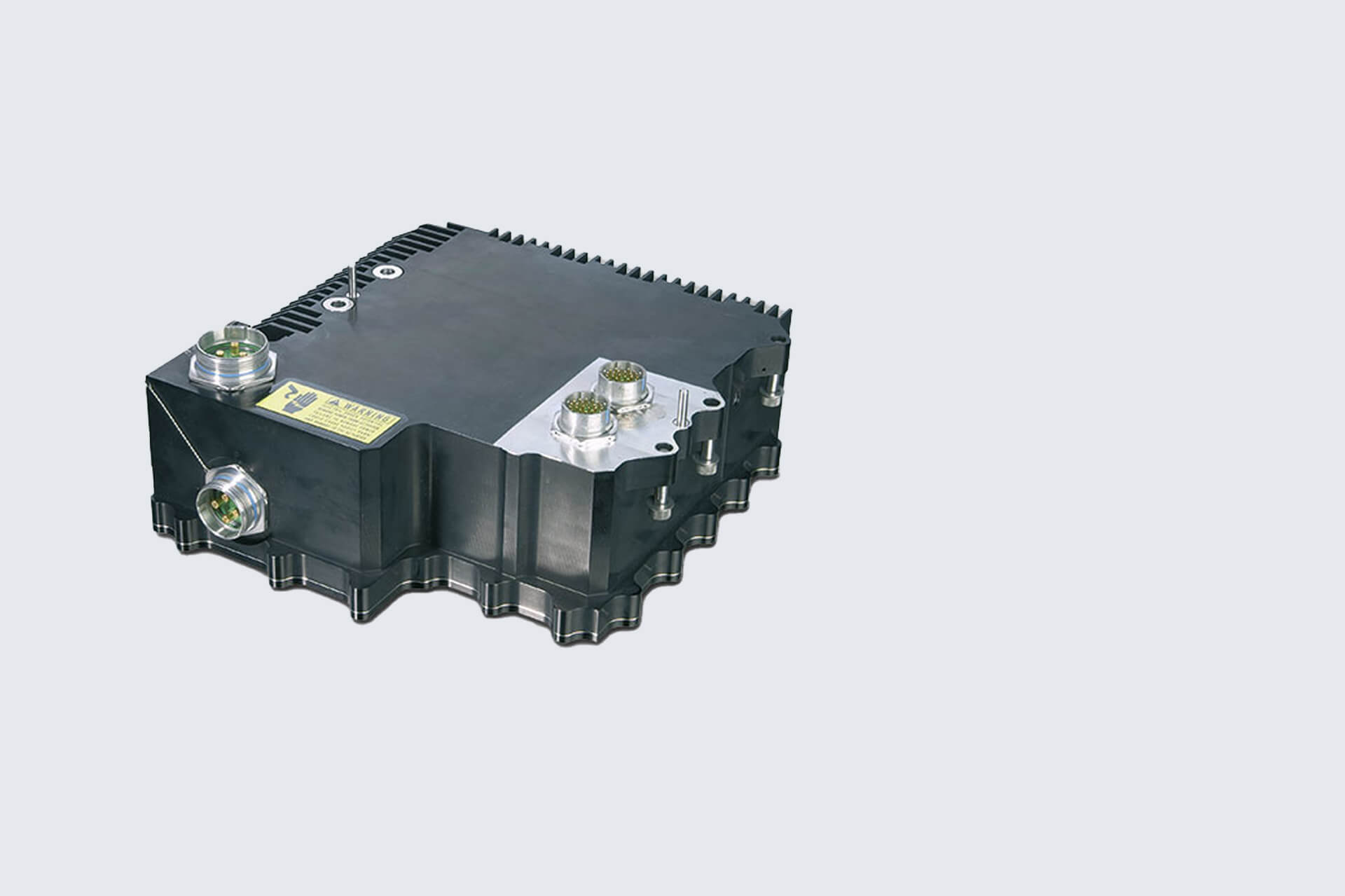

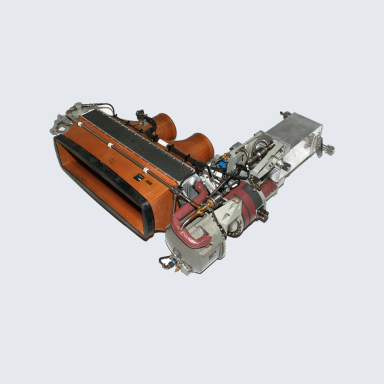

- Power electronics

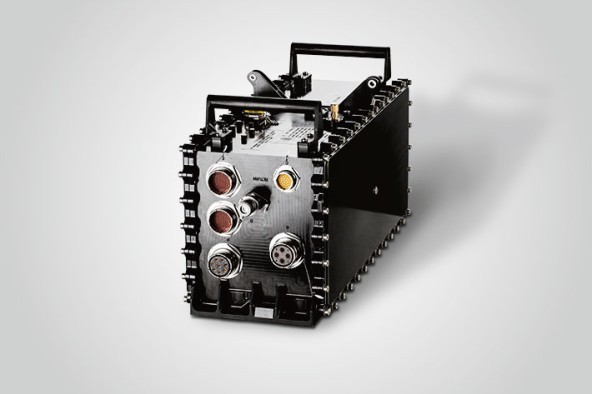

- Signal electronics

- Cockpit static inverter

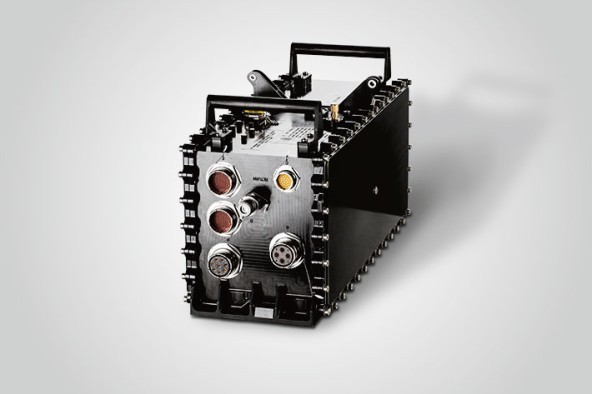

- Remote electronic units

Liebherr’s power electronics and electrical drives are seamlessly integrated into advanced equipment, including flight control actuators, high-speed compressors, electrical air conditioning packs, or electrically driven pumps.

Liebherr’s power electronics and electrical drives are seamlessly integrated into advanced equipment, including flight control actuators, high-speed compressors, electrical air conditioning packs, or electrically driven pumps.

Liebherr's capabilities in electronics

Get in touch

Development competences

Liebherr leverages a wide range of in-house expertise to drive innovation in aerospace technology. From e-drive and sensing solutions to hardware, software, and system development, every stage of design is meticulously engineered for reliability and performance. State-of-the-art test equipment ensures that all systems meet the highest industry standards.

Development lifecycle for power electronics, drive control, and electric motors

- High performance e-drives

- Calculation and simulation of drive systems

- Model-based development of digital drive control algorithms

- Electrical drives test center

RTCA DO-254 compliance for safety-critical DAL A-D applications

- Requirements capture

- Conceptual design / SRU concept

- Detailed circuit design / Circuit design simulation

- Circuit design analysis (tolerances, de-rating, timing, level)

- PCB design / Layout (component placement and routing)

- Mechanical / Thermal design (open or sealed housing)

- Mechanical design analysis (structure, fatigue, tolerance)

- Thermal design analysis

- Commissioning / Engineering tests (maturity, robustness, environmental)

- Verification of electronic equipment according to RTCA DO 160x and others

- AGILE project management

- Synchronous product and process development with enclosed stage-gate-process

Development and qualification of complex software applications and programmable logic devices

- Safety-critical software development tasks (DAL A-D) according to RTCA/DO178x

- From board support package development to complete software systems

- Software platform development

- Software application development

- Model-based software development

- Software verification and HW/SW integration

- PLD development and verification RTCA/DO-254 (EUROCAE/ED-80)

- Project management

Development of complex electronic systems

- Architecture definition (safety critical)

- System interface definition

- Requirement-based engineering (ARP4754A)

- Model-based system engineering

- Simulation and modelling

- Electronic safety assessment (ARP4761)

- Electronic unit verification

- Engineering/ Robustness testing

- Project management

In-house test equipment

- EMC test chamber for: radiated susceptibility, conducted susceptibility, radiated emissions, and conducted emissions

- 3 axis vibration shakers with superimposed temperature

- Temperature and humidity test chambers

- Salt test chamber

- HALT test chamber

- Infrared thermal analysis equipment

- Lightning test / ESD / voltage transients generators