7 minutes - magazine 01 | 2025

Beach Boy

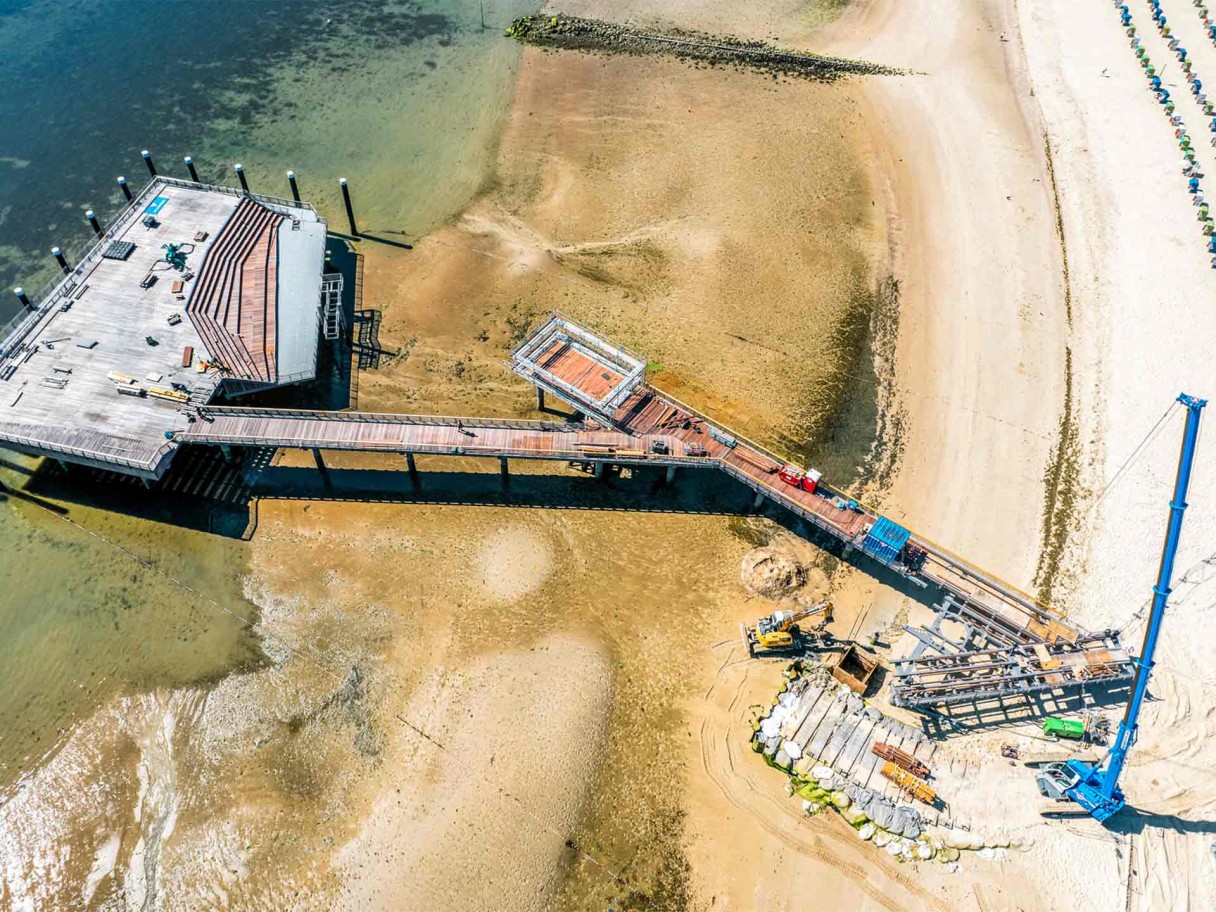

The tranquil island town of Wyk on the German North Sea island of Föhr has been given a new pier. After 20 months of construction, the opening of the impressive “Middle Bridge” into the sea was celebrated last summer.

Complex beach logistics for new pier on Föhr

The Hamburg-based construction company HC Hagemann realised the project on the beach and in the water with expertise, energy and enormous logistics. And with a Liebherr telescopic crawler crane, which was also responsible for transporting the huge quantities of material on site. A short visit to the beach.

The beach supplier: The transport along the beach took place at low tide and preferably in the early hours of the morning, when most holidaymakers were still having breakfast and not sitting in their colourful beach chairs.

Buckets, plastic shovels and toy diggers are usually the only tools that belong on a bathing beach. In Wyk on the island of Föhr, however, the little sandcastle builders have had a lot of competition over the last two summers. Because real construction machinery had to be mobilised to build a new pier. In autumn 2022, the old and increasingly dilapidated “Middle Bridge”, built in the 1960s, was closed to tourists and finally demolished. The traditional wooden bridge is now replaced by a stronger structure made of steel and wood. It is larger and protrudes further into the North Sea than its predecessor.

Job sharing: The Liebherr duty cycle crawler crane which, at the start of the construction work from the working vessel, drove the foundation piles for the structure into the seabed. On land, the crawler crane has taken over this task.

No way through for transport

Projects on islands often require a high level of transport logistics. On page 44 of this issue, we report on a job on a Scottish island that the crane could only reach by landing craft. The crane journey to Föhr was somewhat easier: the team from HC Hagemann – the Hamburg-based company specialising in port and hydraulic engineering, among other things – was able to bring its Liebherr crawler crane to the island on a low-loader using the regular ferry service. On the other hand, transporting the building materials on the last stretch to the construction site was tricky. The middle bridge is located in such a way that holidaymakers can easily walk from the centre of the resort to the pier via the car-free promenade. However, there is no way through for lorries or even large heavy goods vehicles. So the only option was across the mudflats along the beach.

42 long piles support the new “middle bridge”, which juts out around 150 metres into the North Sea at high tide. A good dozen protective fenders secure the pier on the water side.

Imposing dimensions... ... of the new pier. Here, the LTR 1060 lifts a load of timber for the 1,500 square metres of planking on the new construction. The 50 metre wide bridgehead is also intended for events. At the bottom you can see the 60 metre long lane made of steel plates, which enables the crawler crane to drive into the mudflats at low tide.

“The complex transport logistics and scheduling were actually the biggest challenges for us here,” says Torsten Gütschow about his first construction of a large pier. The graduate engineer was responsible for the construction management of the project on Föhr. “All the material came to the island on transporters by ferry from the mainland and was then trans-shipped in Wyk harbour. In the first few months, the material was loaded onto our workboat, which was responsible for placing the foundation pipes and then assembling the steel superstructure from the water with a Liebherr duty cycle crawler crane on board. Later, we used the crawler crane to transport all of our materials the 400 metres along the beach to the construction site.”

Construction helmet instead of swimming trunks: In the summer heat with helmet and construction boots against the backdrop of Wyk: site manager Torsten Gütschow, crane operator Heiko Woidtke and steelworker Czaba Tamasz (from left).

Construction road leads into the sea

“I must have travelled up and down the route 100 times on my LTR 1060,” estimates Heiko Woidtke. He is the driver of the busy crane. However, he was not only responsible for the beach transport, but also for the land-side assembly work on the pier. “We laid a 60 metre long construction road made of steel mats in the mudflats,” explains Torsten Gütschow. “So we were able to use the crawler crane and its 40-metre telescopic boom for installation over the water at low tide.” And a whole lot was assembled: the steel weight of the entire structure alone, with a walkable area of 1,500 square metres, was 750 tonnes.

The steel pipes were up to 19 metres long, which the hydraulic cable excavator from the ship and the crawler crane on land jolted deep into the sand. “With the pipe and shaker, I had around twelve tonnes of load on the hook,” says Woidtke between two lifts, during which he transports timber for the planking onto the almost completed pier. “The assembly work, the transport journeys on the beach and the installation of the piles – the crane does it all with ease.”

Finale: One of the last components of the new pier is installed here. A few weeks later, the inauguration was duly celebrated with a party. The men from HC Hagemann were there as well.

Seasonal, storm and winter breaks

There were several reasons why the construction time for this exciting project took around 20 months. Due to the bathing season on the popular holiday island, work was interrupted in the summer of 2023 after all the foundation pipes had been rammed in the spring. Then there was the wind and weather. “We had a few stormy days here when we couldn’t work. From a wind force of seven Beaufort, which corresponds to a wind speed of around 14 metres per second, we also had to stop work with the cable dredger from the ship.” In addition, there was a three-month winter break with heavy storms and snow on the island. From December to February, the construction site was deserted and the LTR 1060 spent the winter protected in a higher and therefore flood-proof neighbourhood.

This article was published in the UpLoad magazine 01 | 2025.