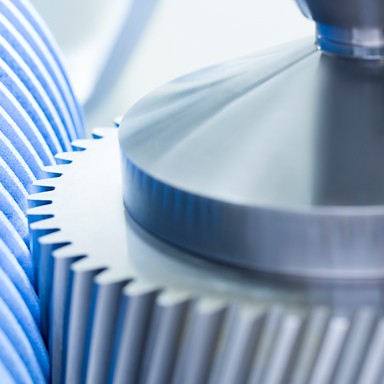

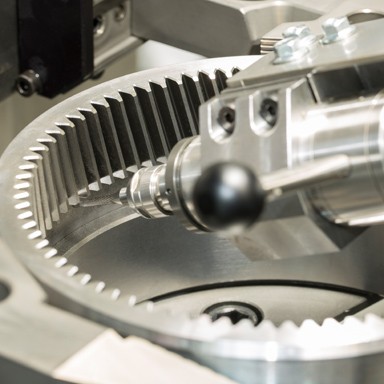

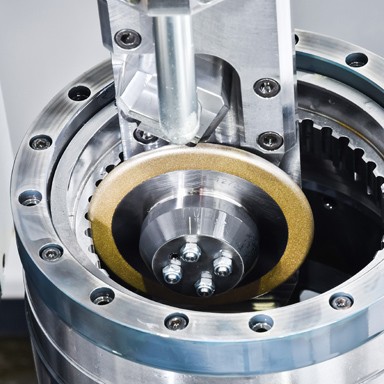

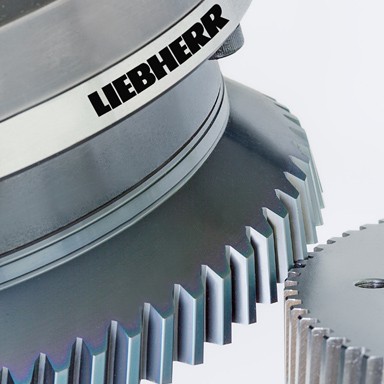

Gear skiving is over 100 years old and has recently been experiencing a renaissance as a flexible and economical alternative to other gear cutting methods. However, this complex process frequently presents great challenges to users. In addition to Skiving3, a “complete package” consisting of machine, tool and technology, Liebherr now also offers skiving tools for suppliers and contract gear manufacturers – and the appropriate consultation, if desired.