LiDIA - engine diagnostic solution

Maximise your productivity with LiDIA

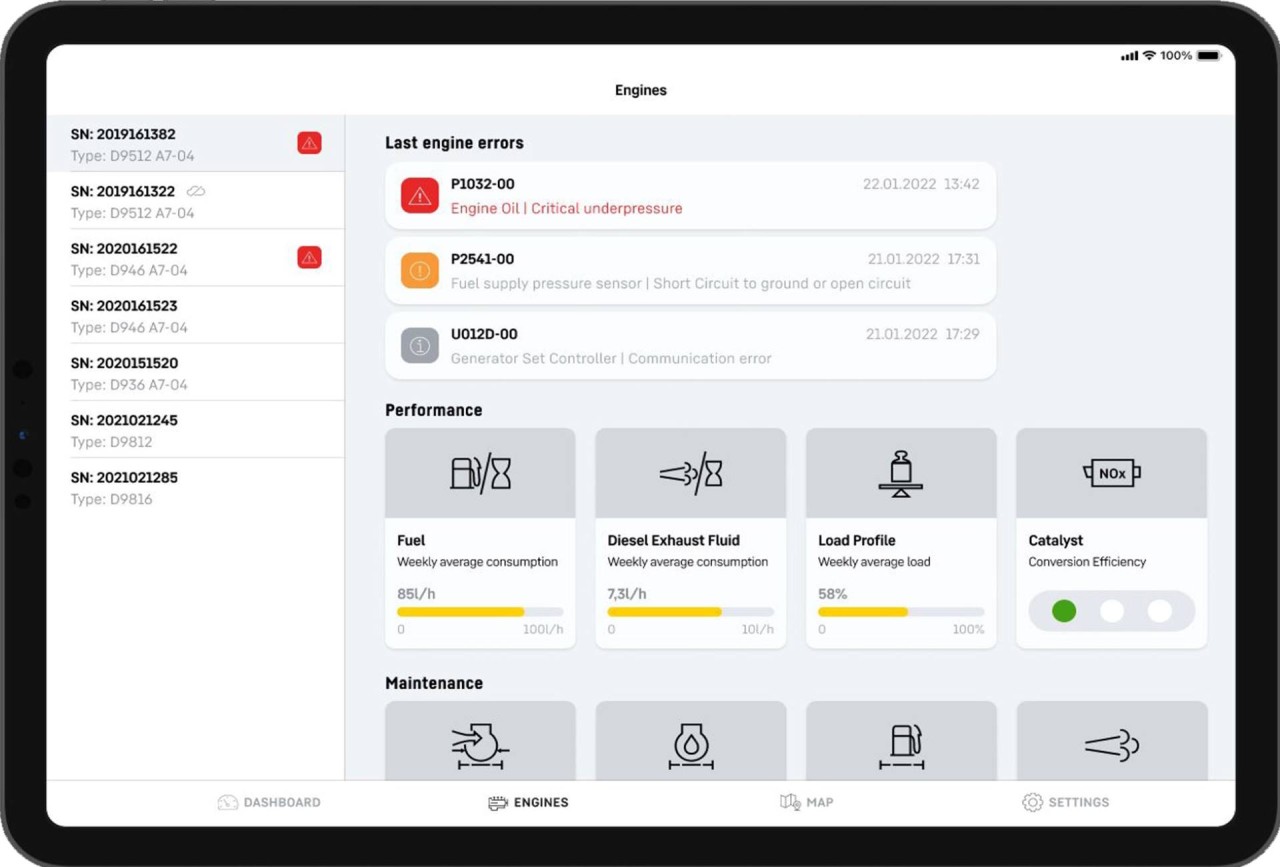

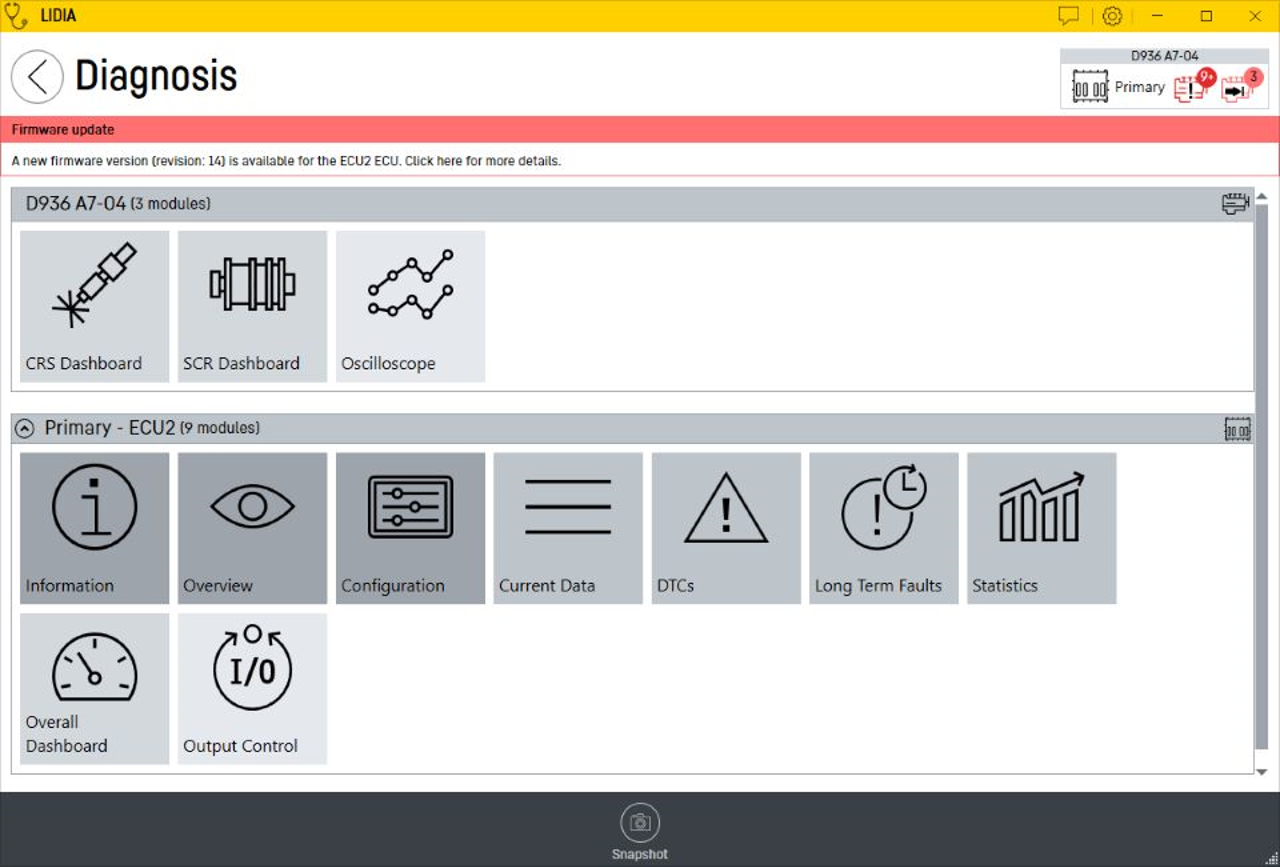

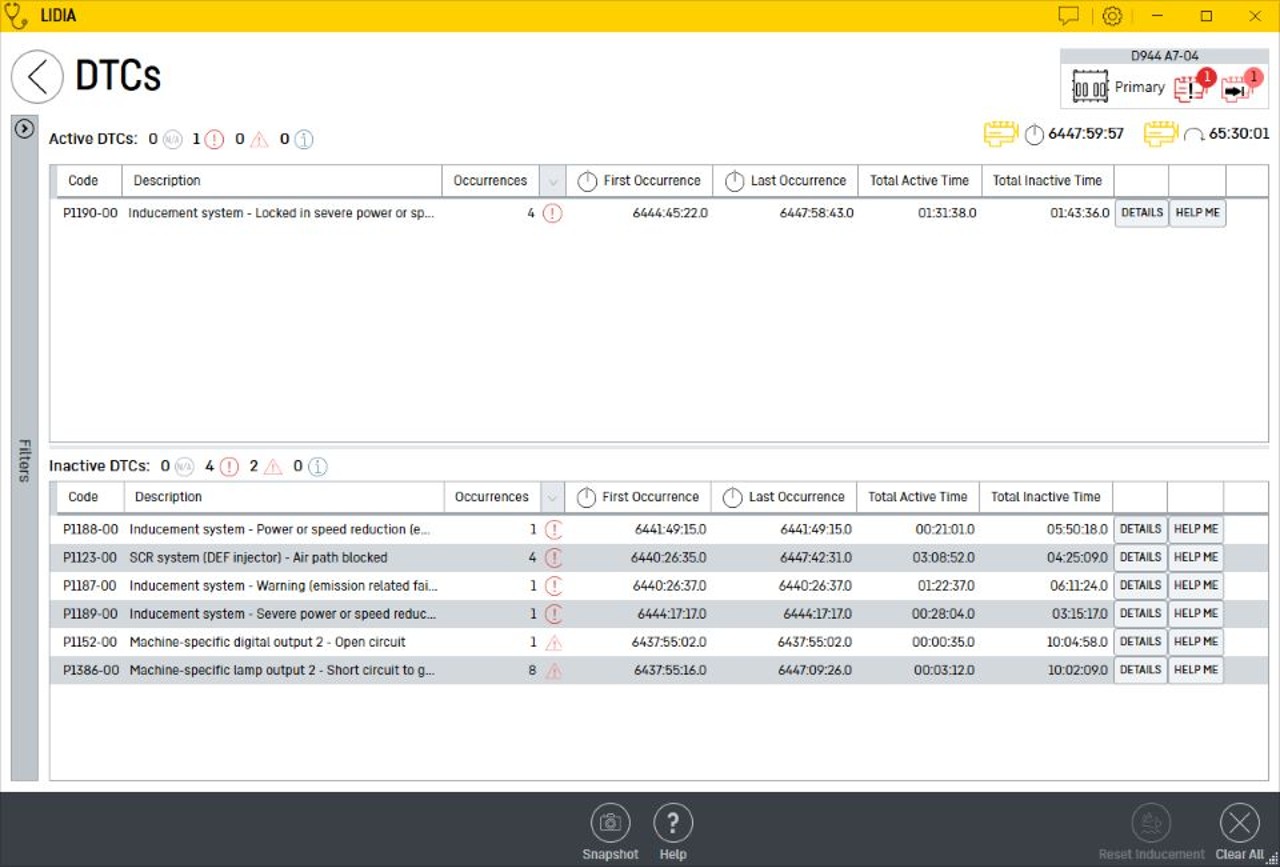

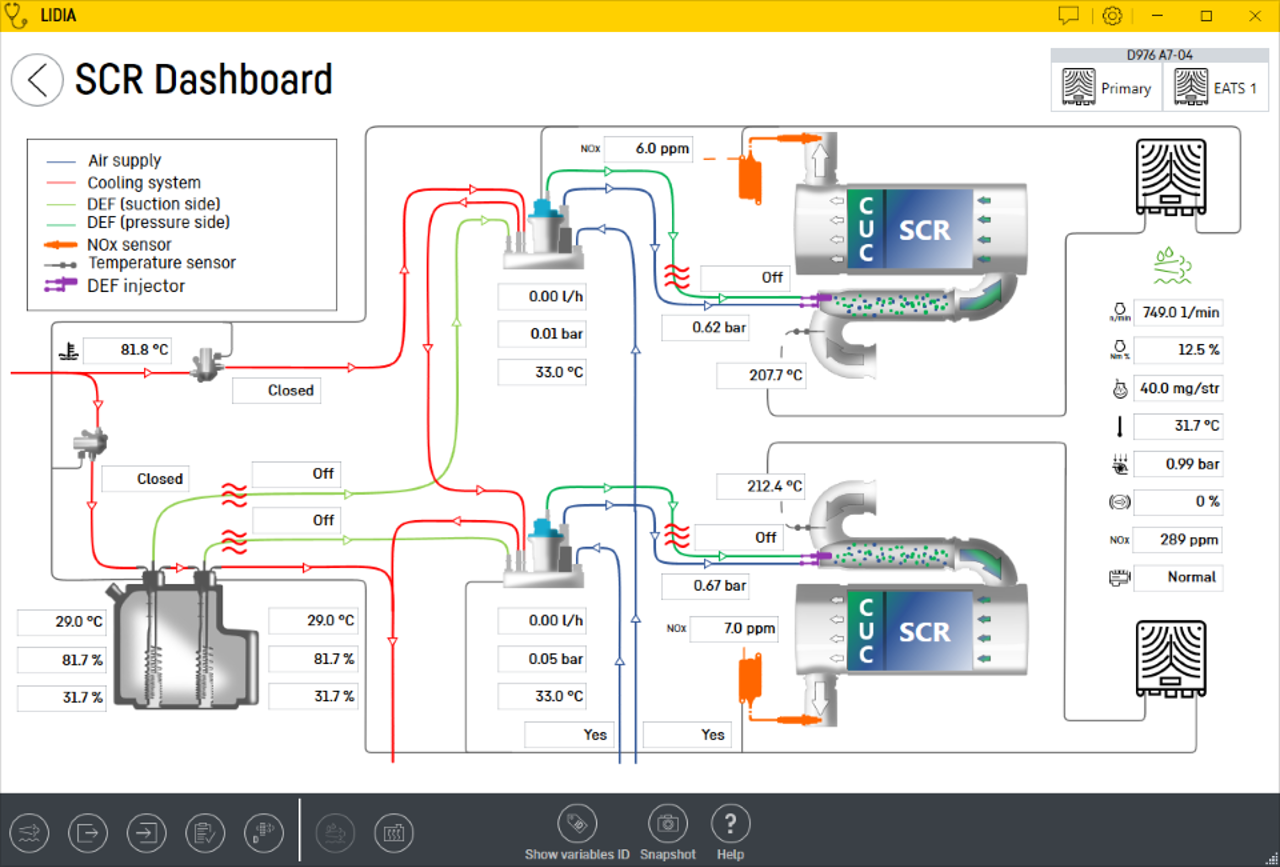

Digital products and services for combustion engines: Minimising downtimes

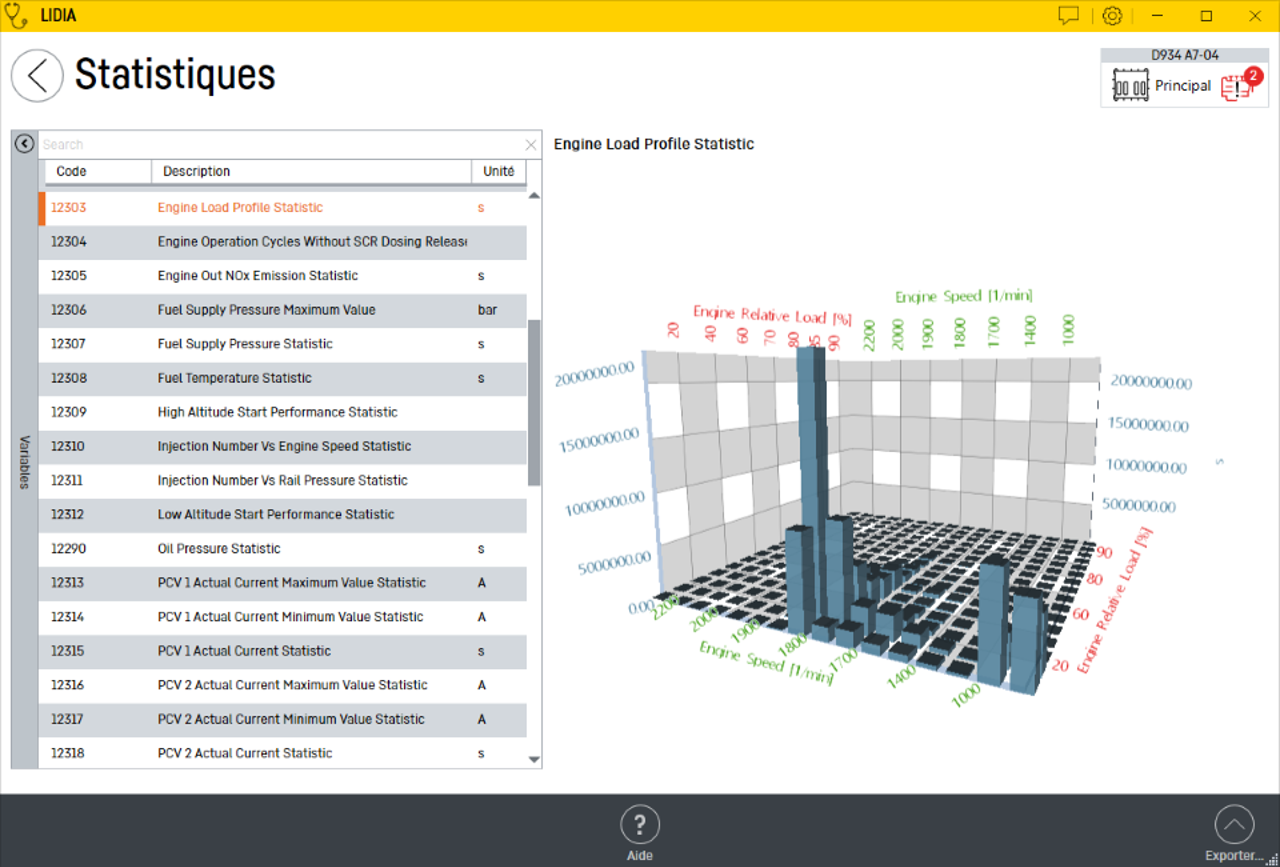

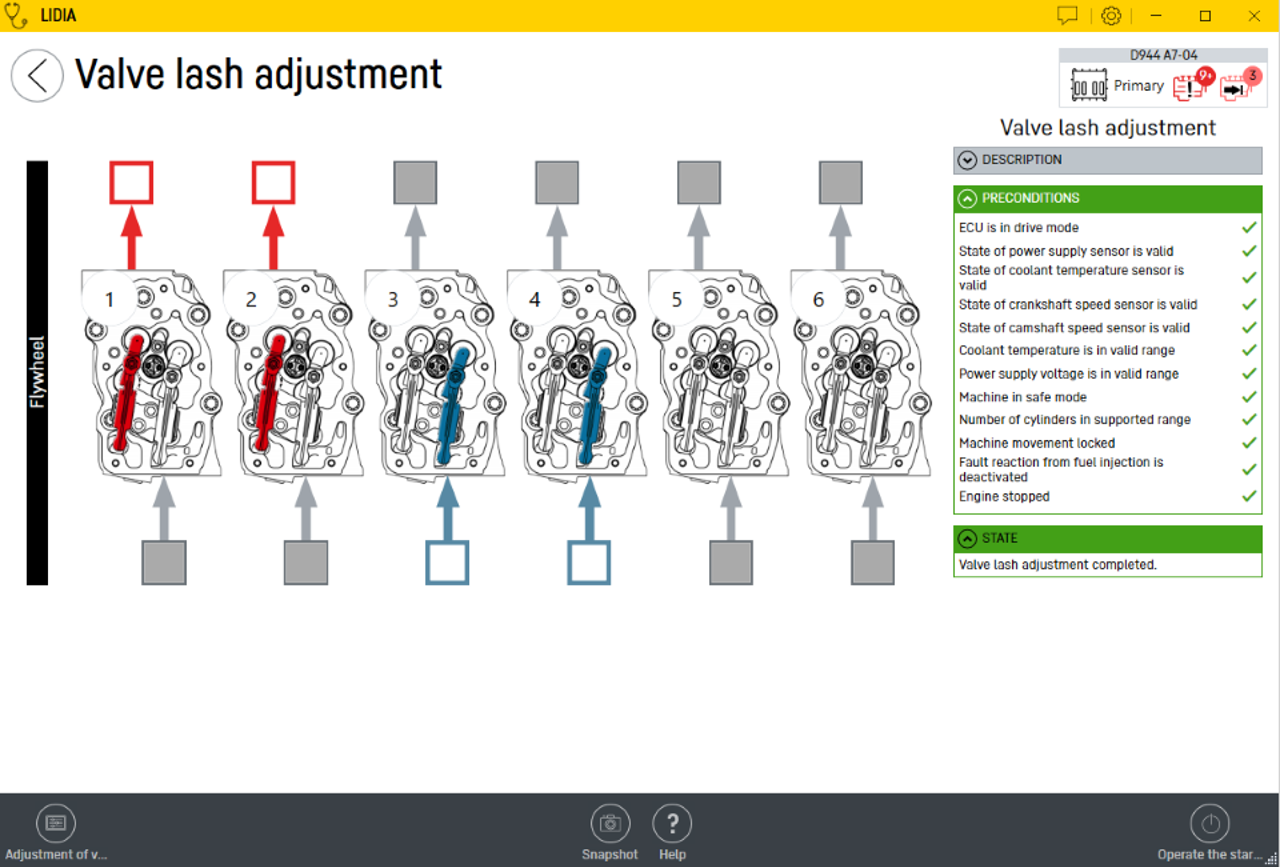

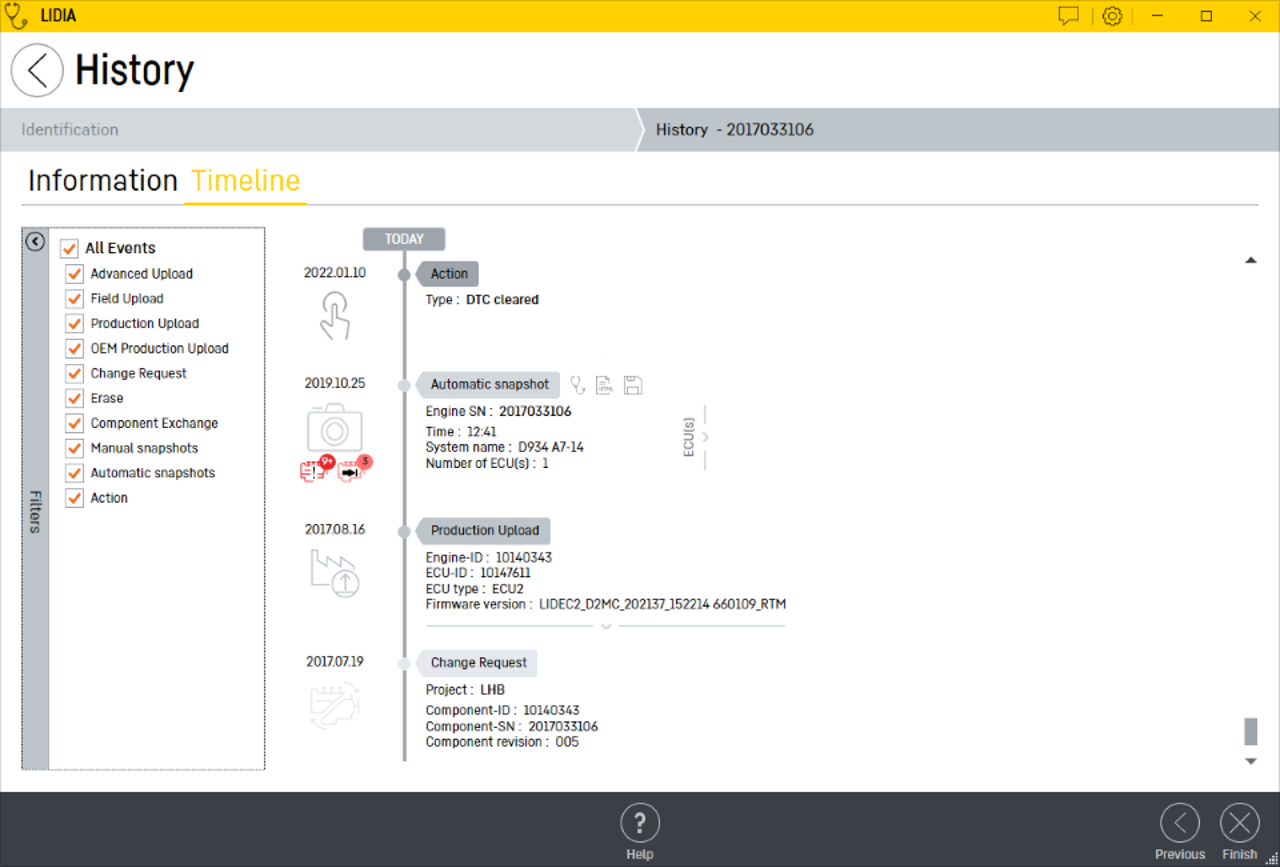

Monitoring the performance of engines is a critical part of every industry. By constantly monitoring and improving the components’ current state, machine downtime can be reduced to a minimum.

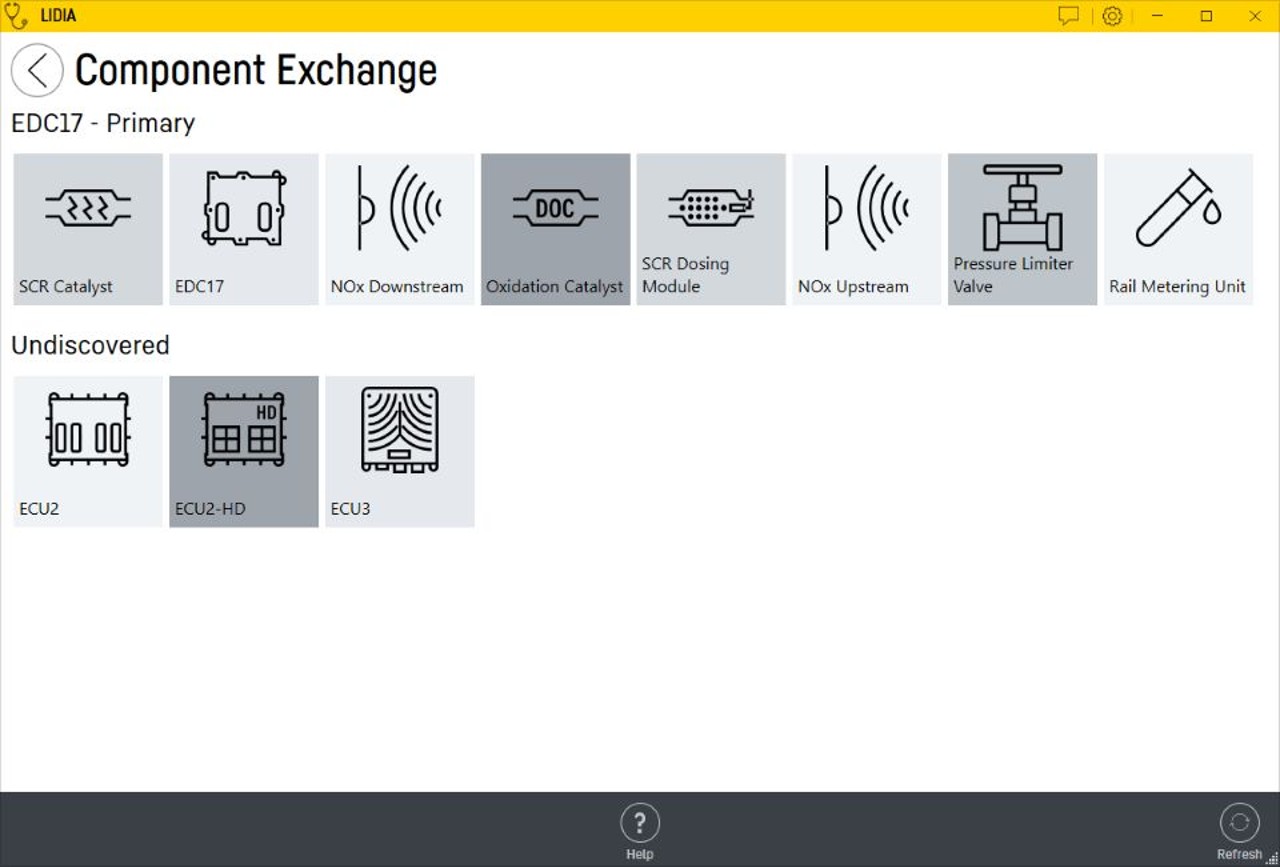

Using diagnostic tools allows customers to properly care for the engine system while maximising uptime and equipment availability. LiDIA is an intuitive and user-friendly engine diagnostic solution, which requires no configuration, facilitates access to the engine environment and reduces the complexity of diagnostic procedures to the essentials.

To further support their customers with the engine performance and maintenance, Liebherr has developed a suite of data-driven digital products and services as part of its combustion engines product portfolio.

Increase overall equipment effectiveness

Reduce costs

Add value to your operations

Decrease carbon print

Features that make a difference

First steps

MyLiebherr

Discover how it works (This is an example of a video integration)

Want to know more?

Contact our sales team via [email protected] or follow us on our Linkedin channel.