LTM 1300-6.2

Mobile crane

LTM 1300-6.2 - Powerful with an innovative drive concept.

The design of the LTM 1300-6.2 saw the first development of an innovative drive concept – the engine in the undercarriage powers the superstructure using a mechanical shaft. This eliminates the need for a second engine. This means one less engine and therefore significantly reduced maintenance costs. The lower weight can be used to increase lifting capacity. On the one hand it is a simple, classic folding jib crane whilst on the other it is a small luffing jib crane on the market for crane operators with a low cost entry point into the luffing jib crane class. It also features high performance, economy and variable boom systems.

Max. load capacity - 300 t

300 t

Telescopic boom - 78 m

78 m

Max. hoist height - 114 m

114 m

Max. radius - 94 m

94 m

Number of axles - 6

6

What's inside

Single-engine concept:

Completely flexible:

Simple:

Flexible at any height:

A great view:

Photo gallery

Technical data

| Max. load capacity | 300 t |

| at radius | 3.00 m |

| Telescopic boom from | 14.70 m |

| Telescopic boom up to | 78.00 m |

| Lattice jib from | 5.50 m |

| Lattice jib up to | 70.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 8-Zylinder-Diesel |

| Drive engine/power | 455 kW |

| Number of axles | 6 |

| Drive/Steering standard | 12 x 6 x 12 |

| Drive/Steering option | 12 x 8 x 12 |

| Driving speed | 85.00 km/h |

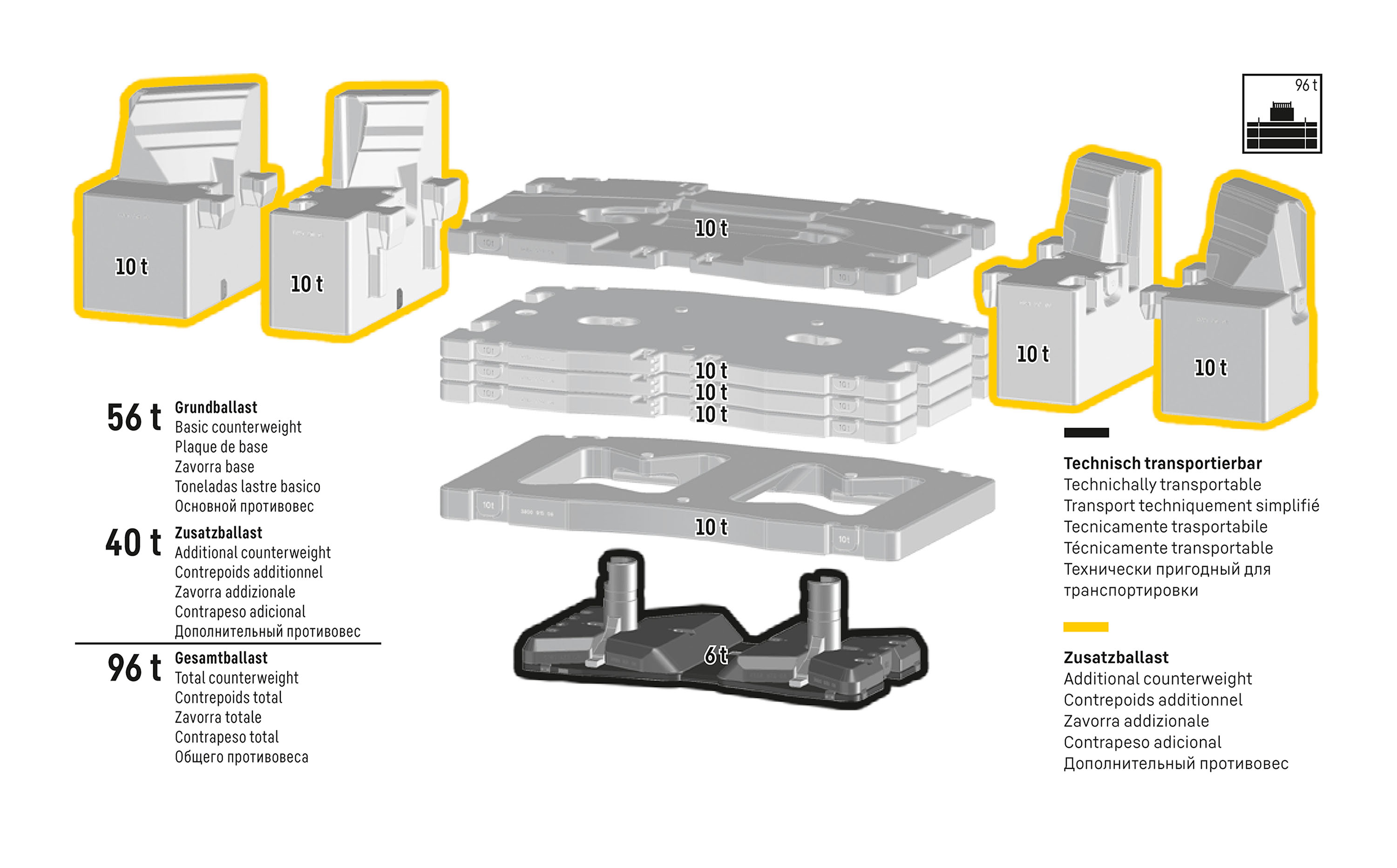

| Total ballast | 96.00 t |

Downloads

Videos

Liebherr mobile crane LTM 1300-6.2

Liebherr mobile crane LTM 1300-6.2

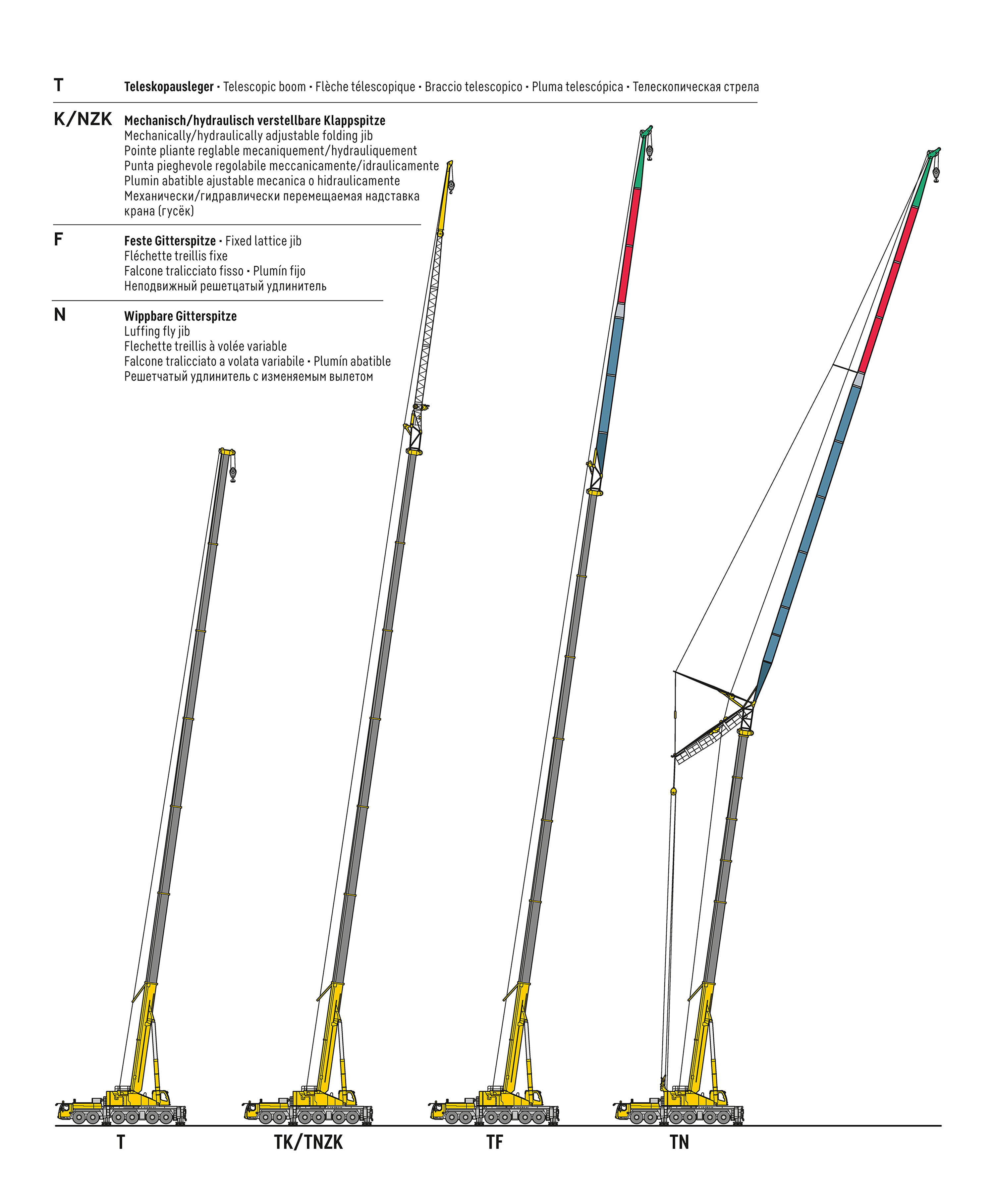

Boom/jib combinations

Boom/jib combinations

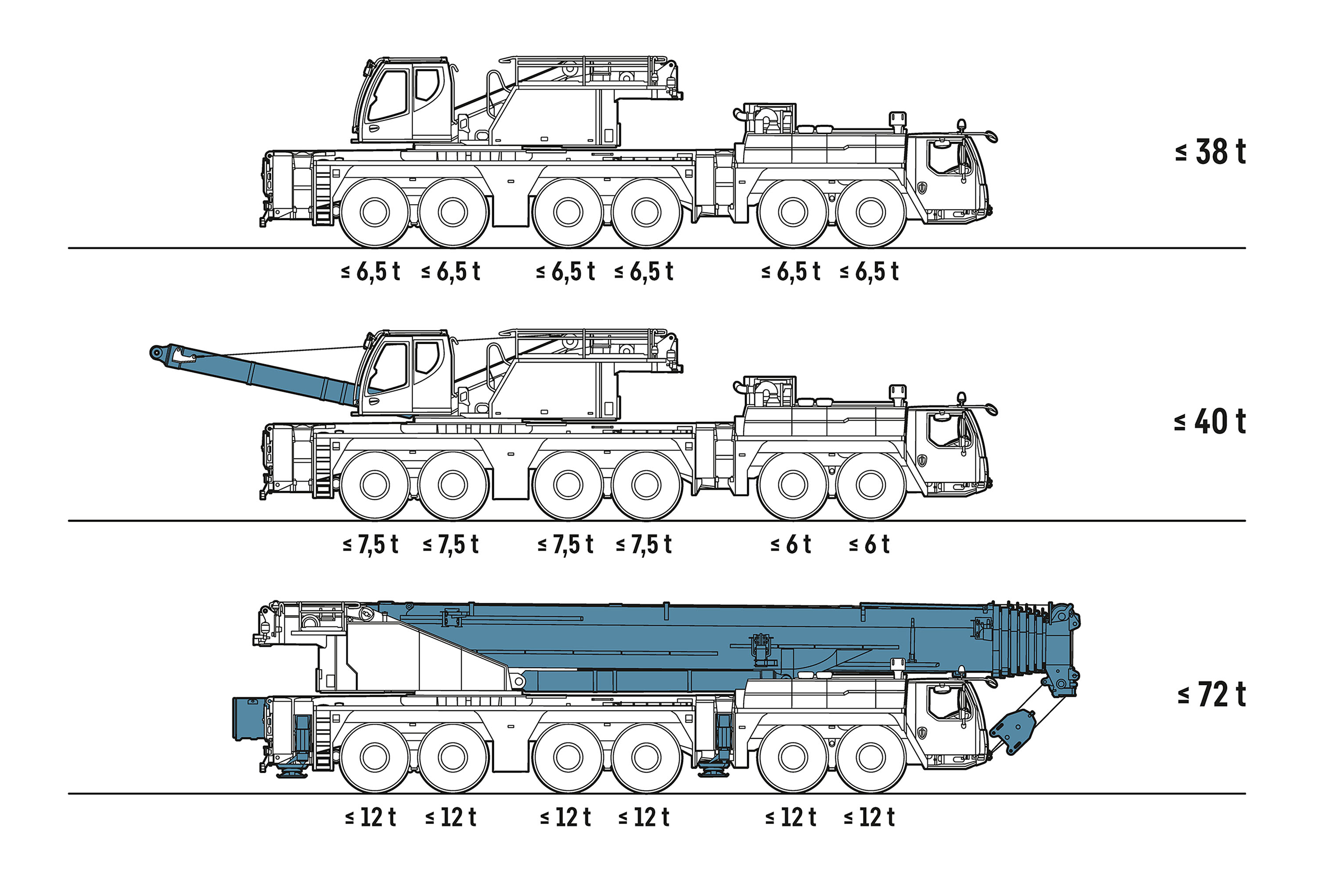

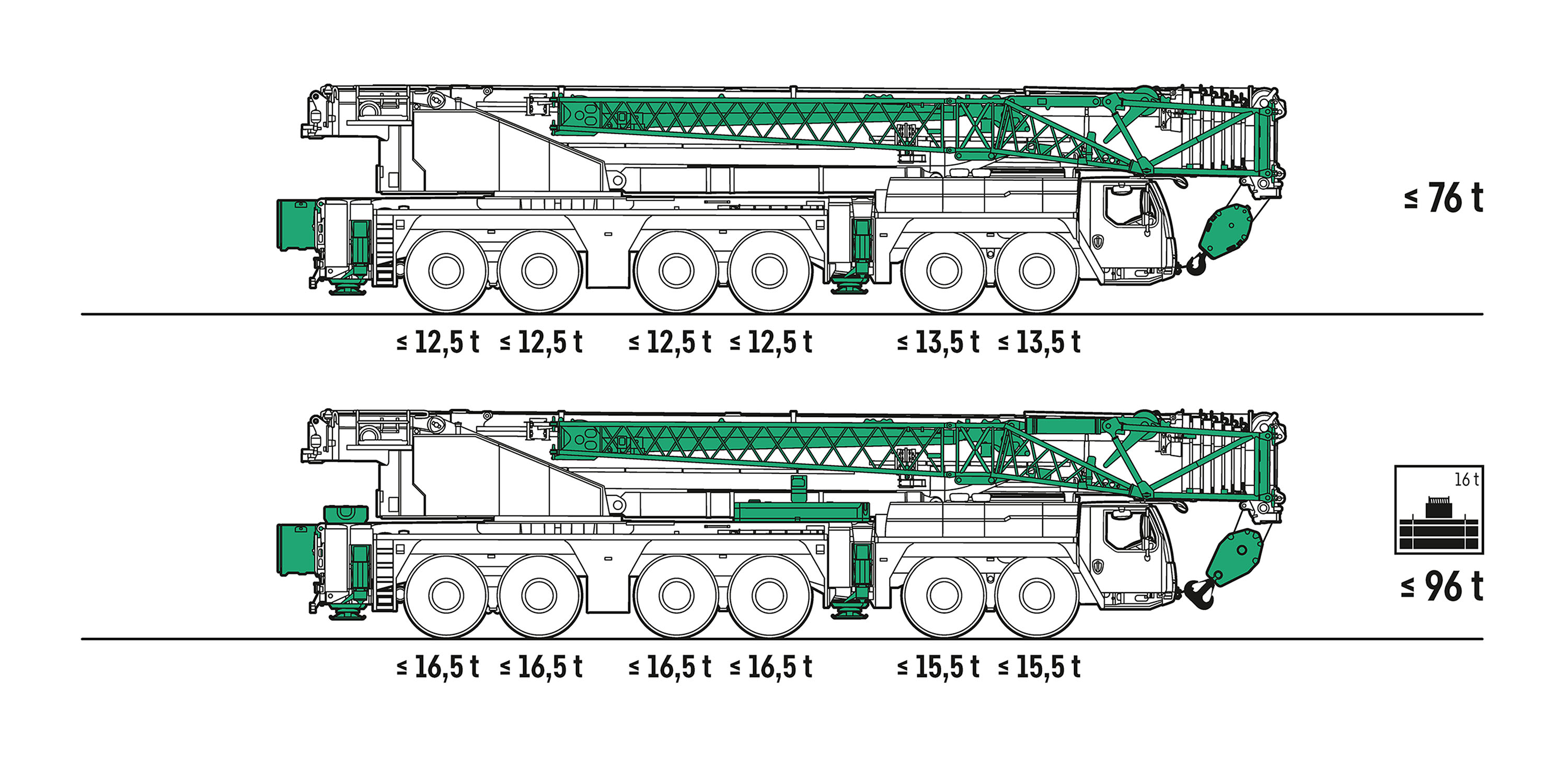

Driving conditions

On-road driving

Jobsite driving

Ballast systems

Counterweight

Technology

ECOmode

ECOdrive

Single-engine concept

VarioBase®

AutoBallast

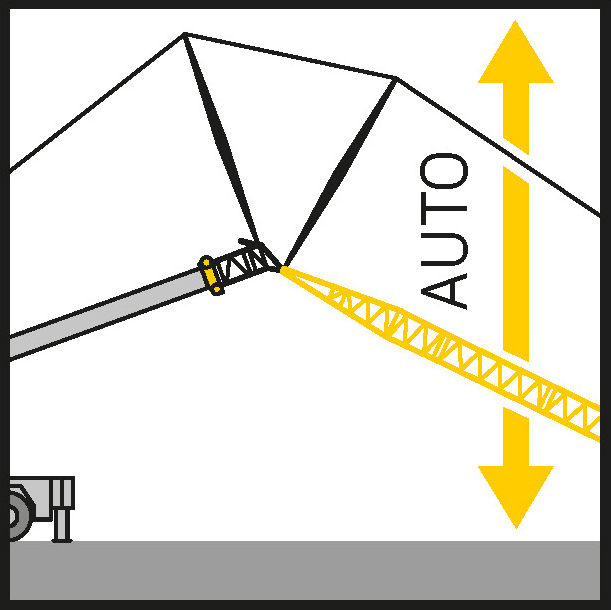

Automatic erection of the luffing jib