HS 8070.1

Duty cycle crawler crane (HS series)

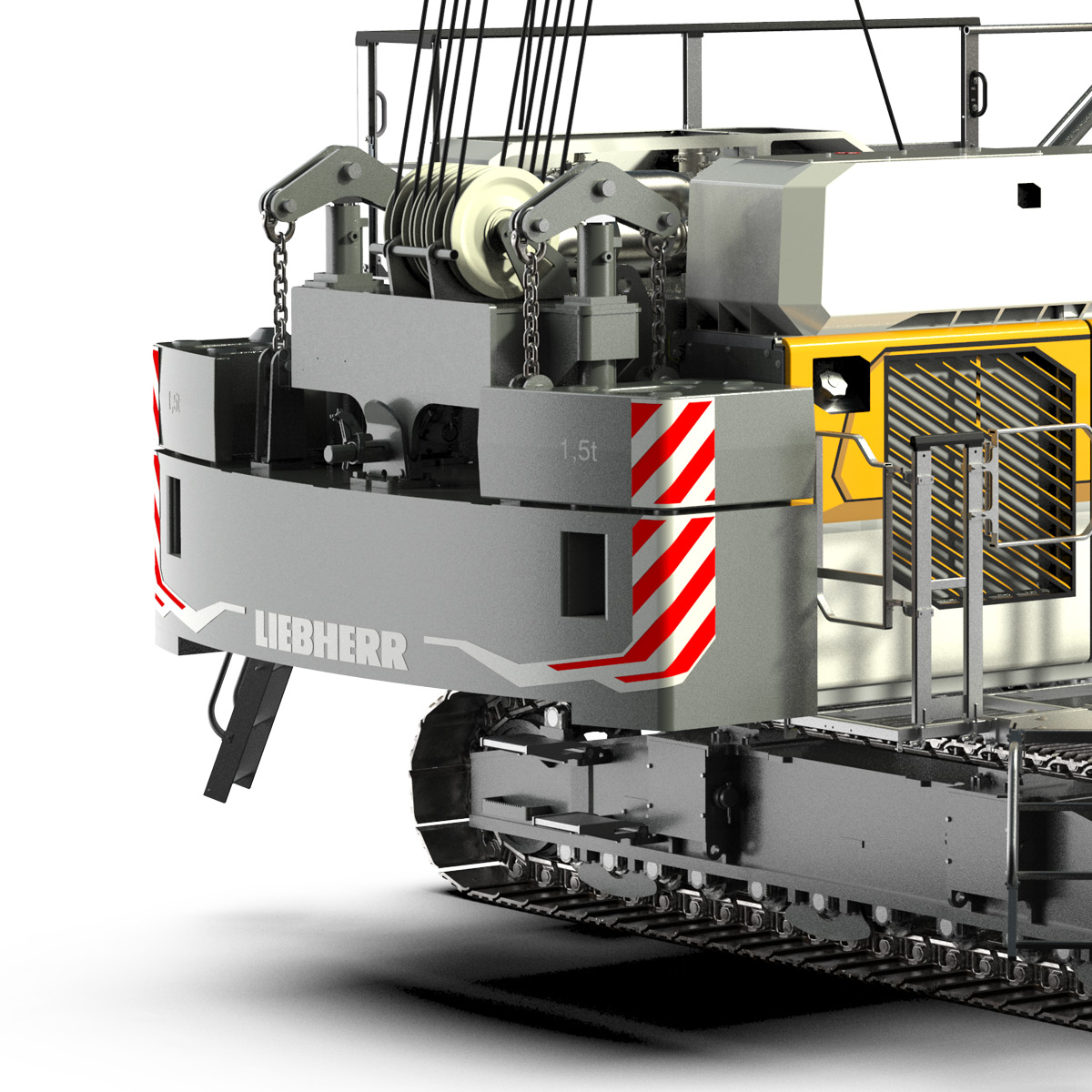

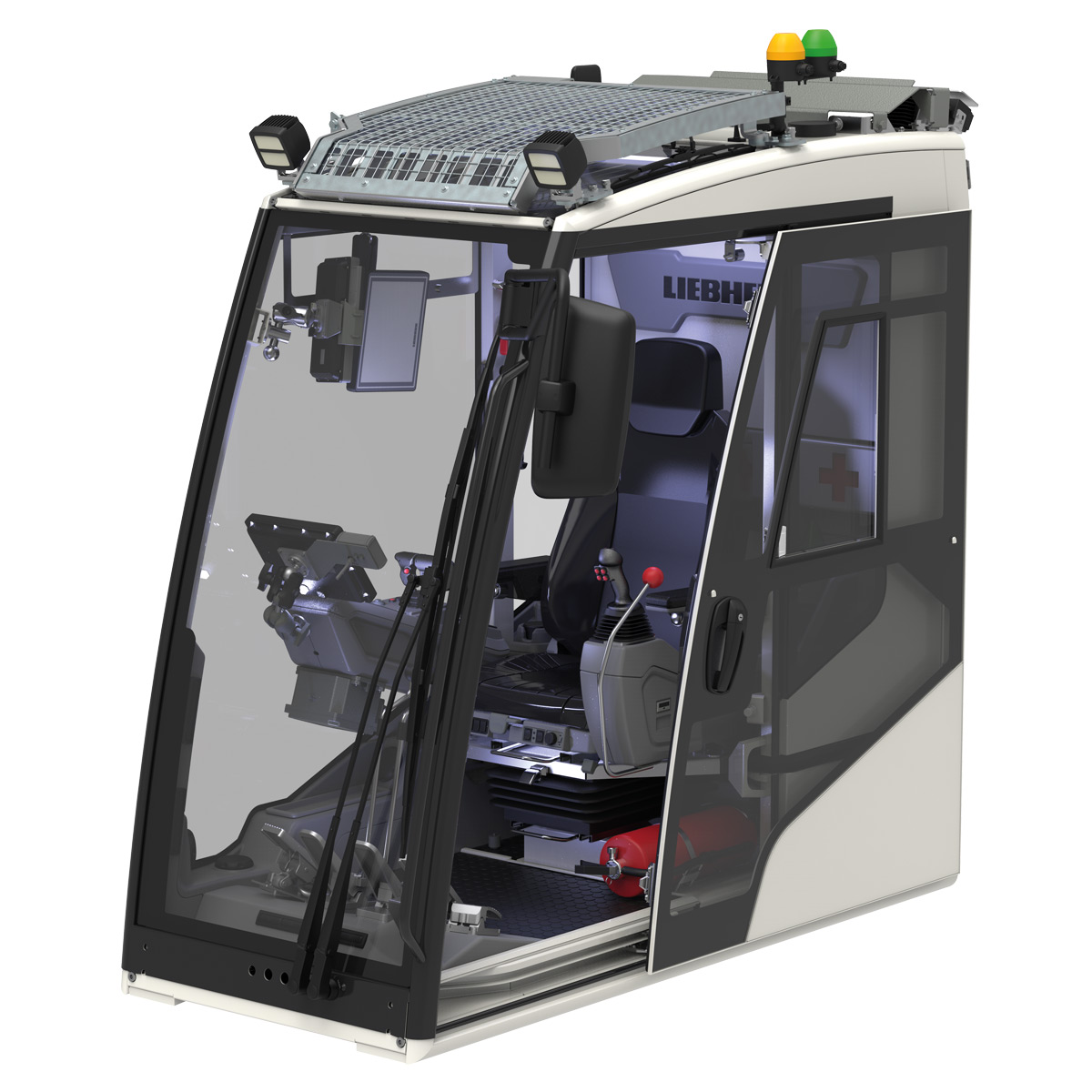

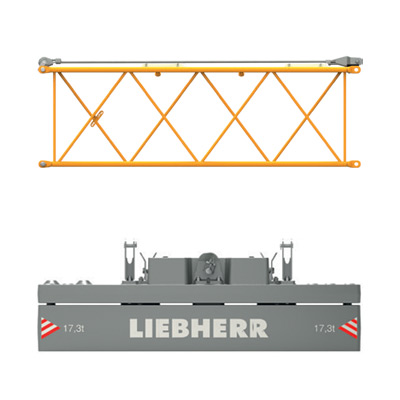

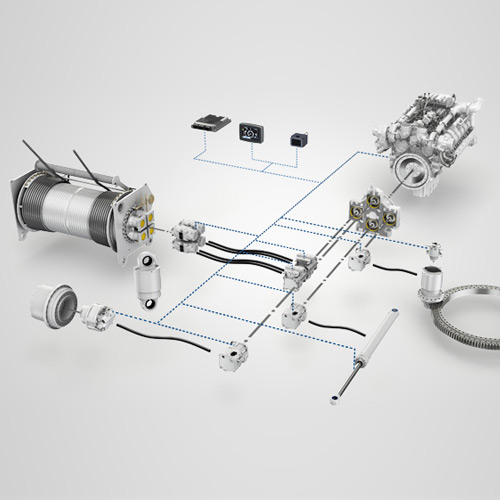

The brand new HS 8070.1 represents the latest generation of Liebherr duty cycle crawler cranes. The machine is driven by an enhanced diesel engine from Liebherr. Noise emission and fuel consumption are significantly reduced. The machine has a load capacity of 70 tonnes and is the first choice for diverse applications: material handling, deep foundation or lifting work.

Max. lifting capacity - 70 t

70 t

Engine power - 320 kW

320 kW

Max. winch line pull - 2 x 200 kN

2 x 200 kN

Max. main boom - 50.00 m

50.00 m