Components

ComponentsLitronic-FMS P30-S planar sensor

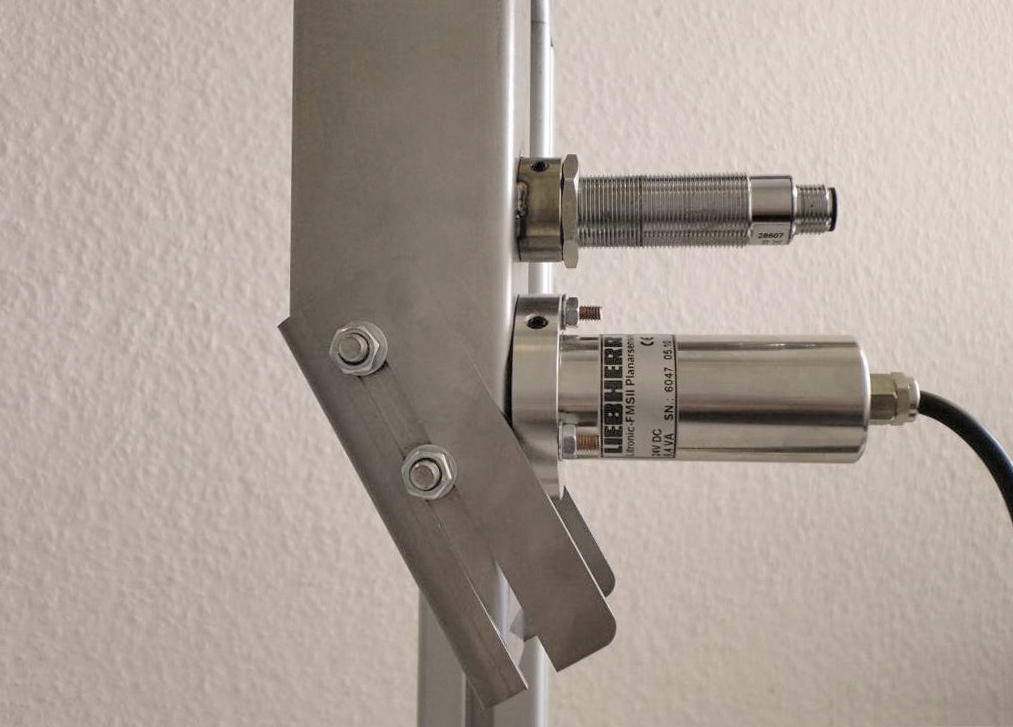

Small, fine, excellent: The Liebherr P30-S sensor in conjunction with the Liebherr FMS moisture measuring installation has become indispensable for many industrial processes.

The “Little One” expanded our product portfolio in 2008.

Measurement by the Liebherr sensor system is based on the physical principle of capacitance determination in the high-frequency stray field.

In addition to their high precision and robustness, the measuring devices from Bad Schussenried are characterised by their reproducibility.

Once the sensor has been calibrated, further measuring points can be set up or devices renewed on this basis at any time without great effort. The plant thus always remains reliable, regardless of its previous term and age.

| Physical principle | Capacity determination in the high frequency stray field |

| Frequency | 20 MHz |

| Measurement location | Constrained installation conditions, pipes, screw conveyors, fluidised bed dryer nerve |

| Measuring range | 0 – 100 % moisture content (measuring window adjustable) |

| Capacity resolution | 3 fF |

| Update cycle | 32.64 ms |

| Sampling rate mean value counter | 16 – 25 106 |

| Maximum attainable measuring accuracy | +/- 0.05 % moisture content 1.) |

| Data interface | RS-485 EIA-485 |

| Maximum bus length | 1200 m |

| Measurement value transfer | half-duplex |

| Bus arbitration | Master/Slave |

| Data format: | 9600bit/s 9 data, 1 stop |

| Log | proprietary multiprocessor log |

| Max. number of sensors on the bus | 16 |

| Measured value streaming | simplex |

| Bus arbitration | automatic |

| Data format: | 19200 bit/s, 8 data, 1 Stop, no Parity |

| Output | binary 2 temperatures and raw value |

| Output cycle | 33 Hz |

| Max. number of sensors on the bus | 4 |

| Power supply | 8 - 30V, 0.4 VA |

| Temperature measurement measuring range | -10 – 90 °C |

| Measuring accuracy temperature measurement | +/- 0.5 °C |

| Operating ambient temperature | 5 – 72 °C |

| Working temperature - electronics | -20 – 80 °C |

| Storage temperature | -25 – 80 °C |

| Protection class | IP68 |

| Connection cable type | UNITRONIC®ROBUST C 7x0.14 shielded |

| Connection cable length | 6 m |

| Wearing protection | PEEK |

| Housing/flange material | V4A (1.4404) |

| Dimensions: Ø/Length | 30/94 mm |

| Weight without cable | 0.500 kg |

1) representative of the batch or the time window in the Contiprocess, in conjunction with the associated Litronic-FMS II evaluation device, material-dependent, with ideal flow behaviour and with proper calibration

Characteristics

• Pure capacitive measuring method

• Sensor exchange without recalibration

• Sensitivity adjustable in 3 steps

• Integrated microprocessor with mean value calculator

• Material flow detection

• Temperature compensation

• Limit value evaluation

• Direct digital measurement value determination

• Stainless steel housing

- Indirect measuring method: Capacity determination in the high frequency stray field. This method uses the different dielectric constant (permittivity) of water and different materials (solids and liquids).

- Fully reproducible sensors: If the plant is subsequently extended with sensors or if sensors are replaced, no recalibration is necessary thanks to the built-in microprocessor.

- Waterproof and dustproof: The sensor is also suitable for the harshest environments thanks to its IP68 protection class

- High sensitivity: The sensor surface is made of the high-temperature resistant, thermoplastic material PEEK.

- Process control and regulation: Thanks to extensive interfaces, the moisture measurement can be integrated into process control systems and controls.

- Cost saving: Time-consuming and costly laboratory analyses are no longer necessary or can be reduced.

- Temperature measurement/temperature compensation: The sensor can also be used to determine the temperature of the medium.

- Limit values: Maximum or minimum limits can be set using the software. Light or sound signals can be triggered if required.

- Mean value calculator: The sensor passes on already averaged values to the FMS evaluation and transfer module.

- Small but powerful: The P30 has a length of 80 mm. The diameter is 30 mm.

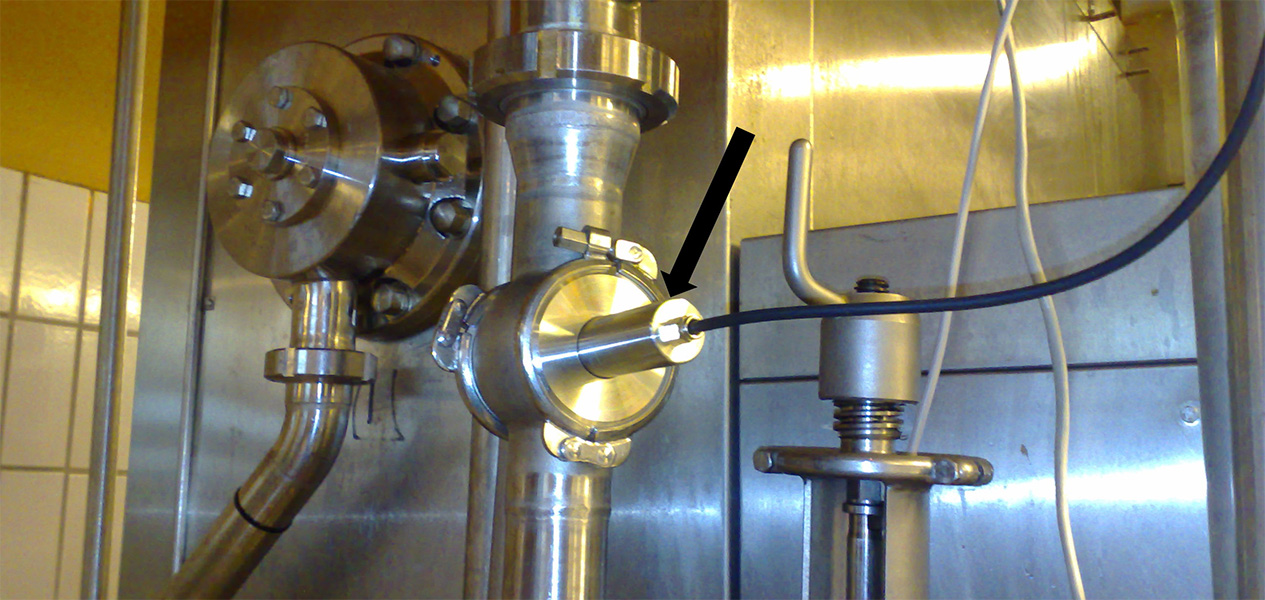

- Confined space conditions: The smallest of our sensors fits into even the tightest installation locations.

- Increased temperature ranges: For use at increased material temperatures, we offer our P30-ST sensor, which is designed for max. 90 °C material temperature.

- Weld-on fittings: For sensor installations in pipes for DN40 lines and pipe from 3 inches and up to a wall thickness of 25 mm, we offer you our appropriate brackets.