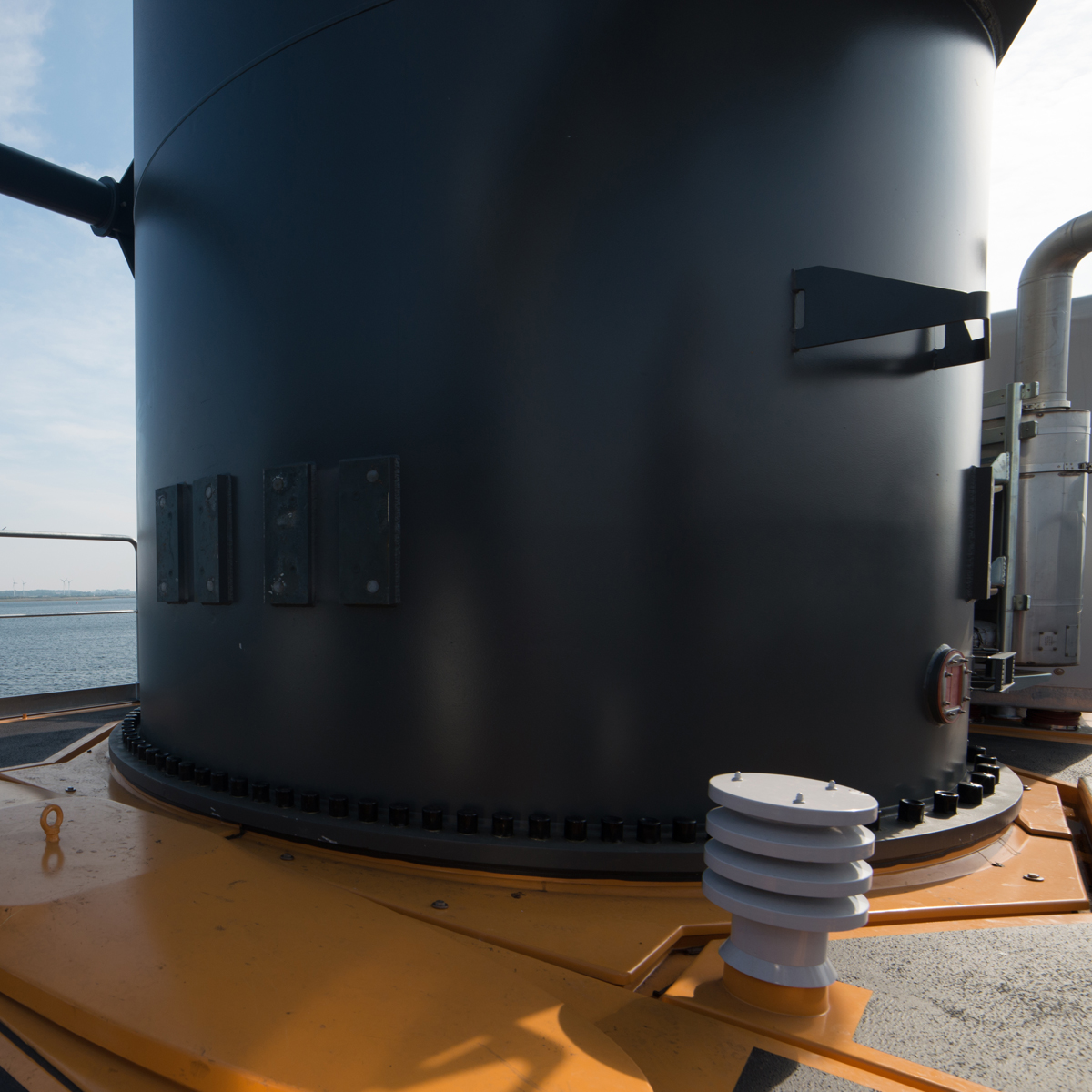

LHM 550

Mobile Harbour Crane

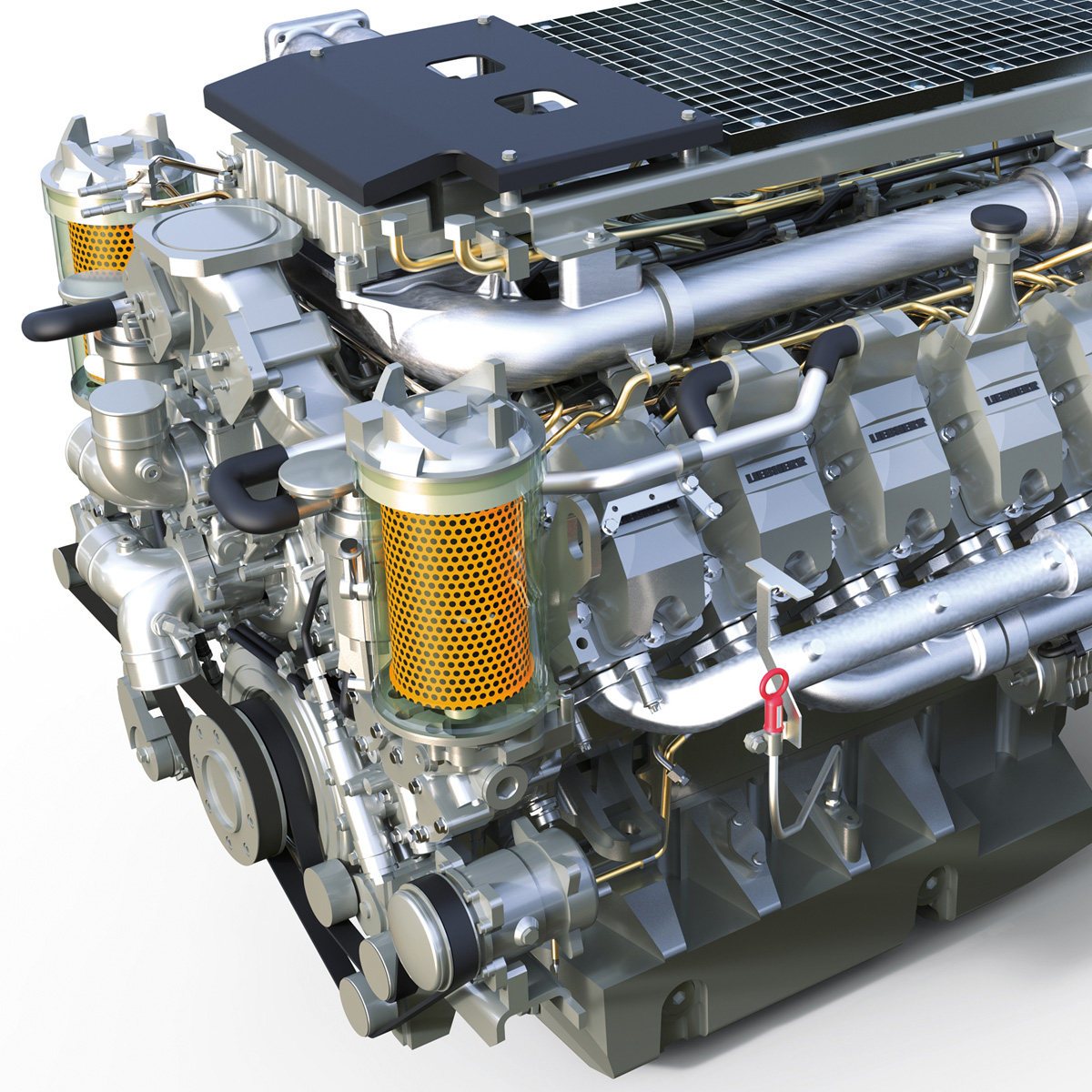

With an outreach of 54 metres, the LHM 550 is the perfect crane for handling bulk cargoes in the Capesize ship class. For container handling ships of the New-Panamax class are the optimal working environment for the LHM 550. General cargoes and heavy-duty lifting up to 154 tonnes complete the range of applications of this crane type.

Lifting capacity (max.) - 154 t

154 t

Jib length - 54 m

54 m

Total weight - 439 t

439 t

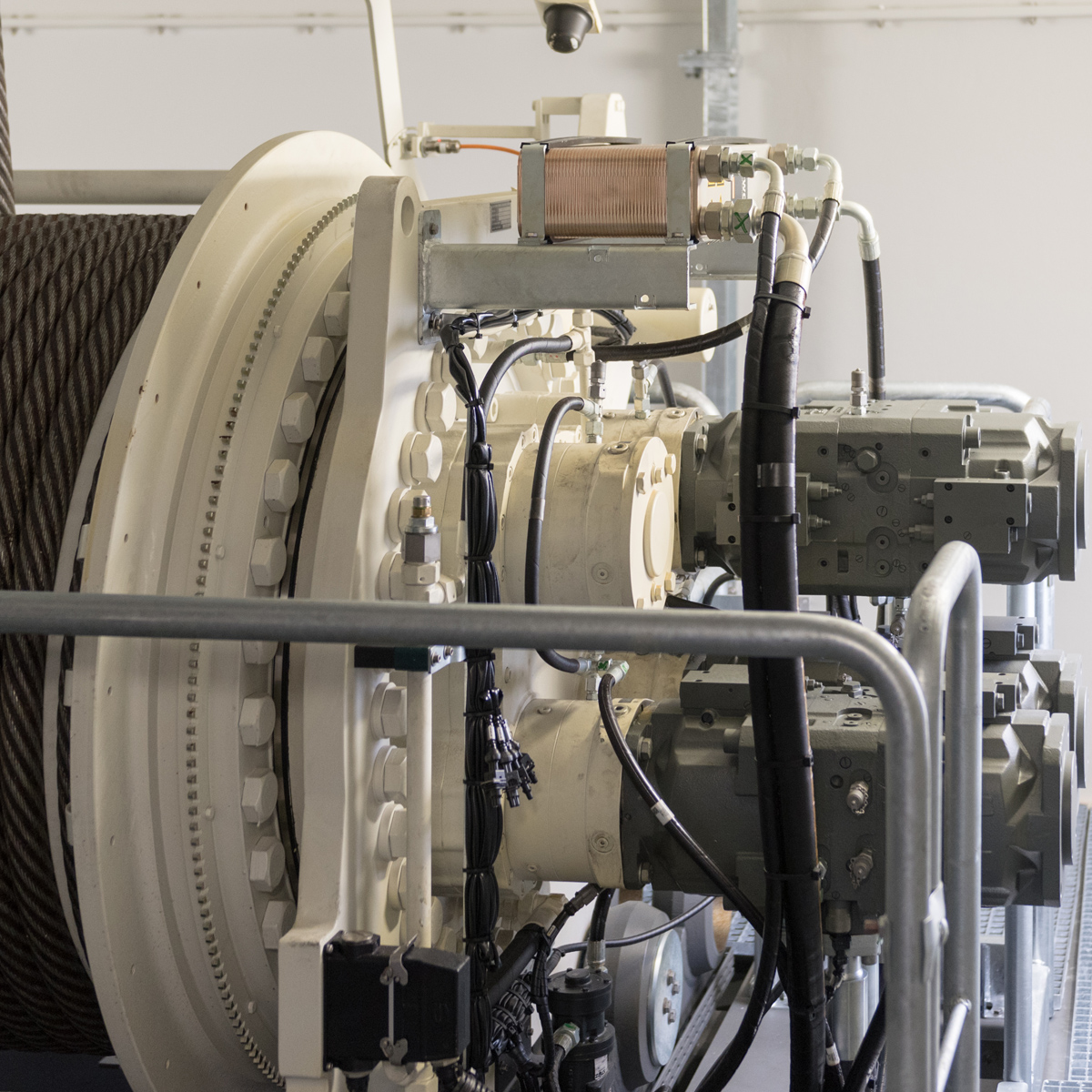

Hoisting/lowering max. - 120 m/min

120 m/min