About Liebherr

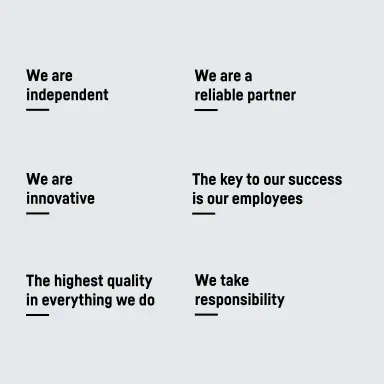

Liebherr sees itself as a pioneer. Based on this attitude, the more than 50,000 employees play a decisive role in shaping technological progress in numerous industries and are already dedicating themselves today to the challenges that customers will face tomorrow. The management of the Liebherr Group is still in the hands of the Liebherr family.

News

Press contact

Journalists can get a competent response to their queries here regarding our products or the company.