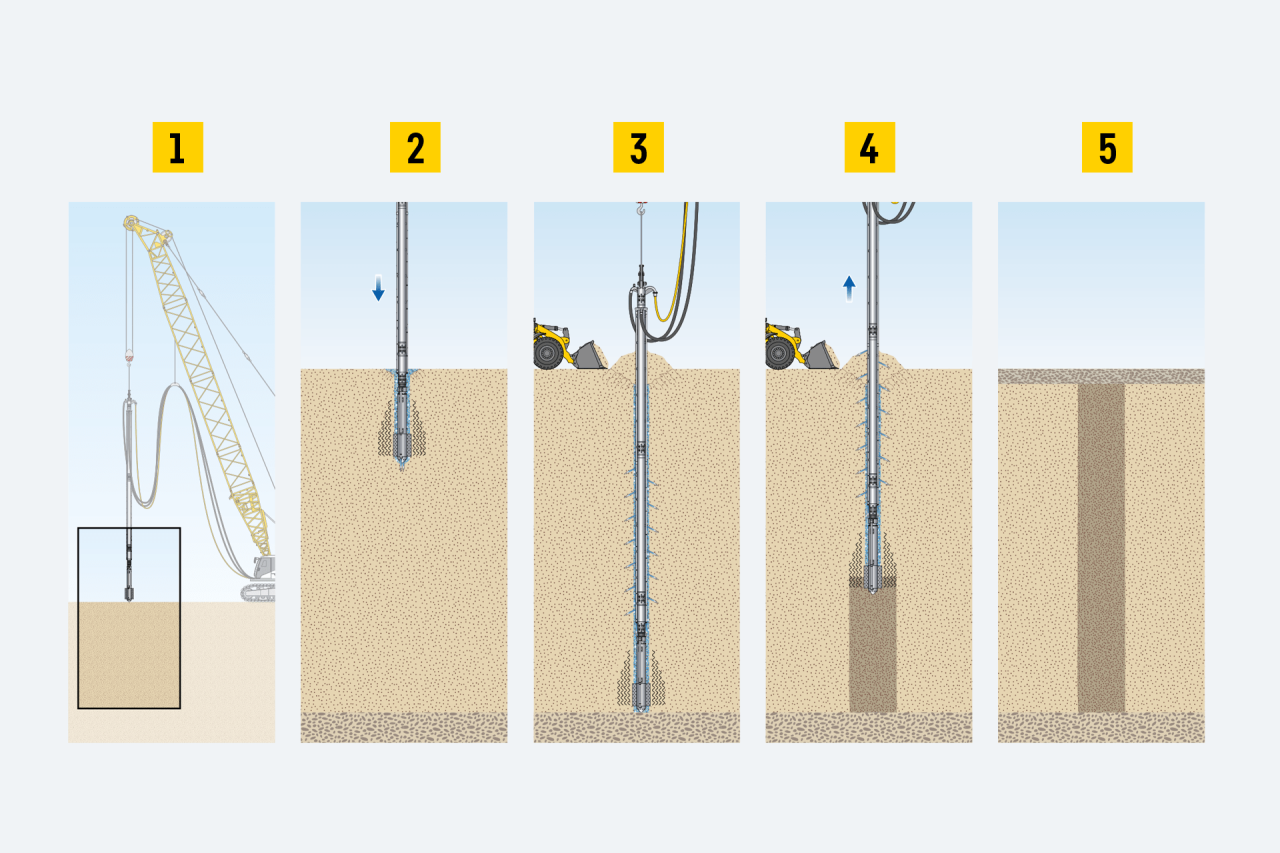

For vibro-compaction non-cohesive soil is compacted using a vibroflot. The vibroflot is mounted on the lower end of a pipe on a lift crane, duty cycle crawler crane or rig, either free hanging on ropes or via a leader and sunk into the ground. Through the vibration the soil grains change from their initial loose layering to a denser layering. Around the vibrator a cylindrical compacted soil structure is created.

01/06

Machines

Results 1-2 of 3

1

2