Machines and solutions that inspire

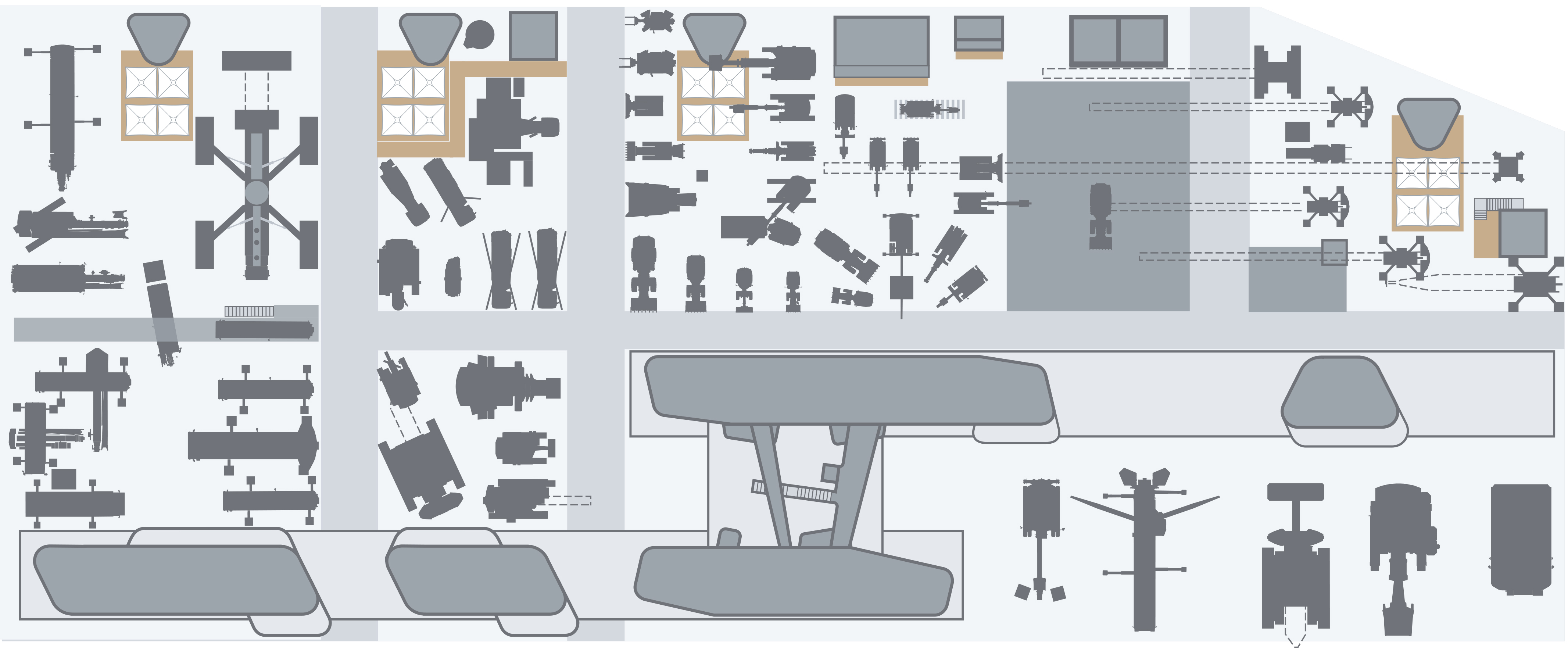

Earthmoving and material handling

Liebherr is helping to shape the construction site of the future – making them even smarter, more efficient and more sustainable. At Bauma 2025, we are presenting the very latest innovations in the fields of earthmoving, material handling and attachments. From alternative drive technologies and highly automated machines through to digital service solutions. Visit our booth and discover groundbreaking technologies that are setting new standards in earthmoving and material handling.

Earthmoving

*This audio guide is spoken by an AI voice.

World exclusives for alternative drives

The construction industry is on the verge of a revolution: the focus is increasingly shifting to efficiency and reducing emissions. Liebherr is actively helping to shape the future through economical and eco-friendly drive solutions in the field of earthmoving and material handling.

- L 507 E

- L 566 H

- LH 40 M Port E

- LH 60 M High Rise Port E

- A 918 E

- R 920 E

_w592.webp)

The battery-driven L 507 E wheel loader from Liebherr combines the known strengths of the Liebherr stereoloader with a cutting-edge electric drive. It produces zero local emissions, is quiet in operation and yet still delivers the same performance level as conventionally driven wheel loaders.

_w592.webp)

The battery-driven L 507 E wheel loader from Liebherr combines the known strengths of the Liebherr stereoloader with a cutting-edge electric drive. It produces zero local emissions, is quiet in operation and yet still delivers the same performance level as conventionally driven wheel loaders.

Crawler excavators at Bauma 2025

Liebherr’s range of crawler excavators comprises some 30 models weighing between 14 and 100 tonnes, including electric models. They are suitable for conventional earthmoving works, quarrying and demolition works, material handling and even pontoon and tunnel construction.

Wheeled excavators and railroad excavators at Bauma 2025

Discover the new generation of wheeled and railroad excavators with new operator’s cab and intuitive operation. Presented for the first time: the new models in the smallest weight class for more versatility and the RE 25 M with innovative undercarriage. The A 918 Compact impresses with its pioneering operation and the A 918 E operates emission-free.

Articulated dump trucks at Bauma 2025

The articulated dump truck stands for maximum performance and efficiency in off-road use. The robust, precise and all-terrain machine is designed for maximum productivity. The powerful drivetrain offers more material movement in the shortest possible time.

Wheel loaders at Bauma 2025

The Liebherr wheel loaders are always under further development and have been optimised to meet the diverse requirements of a wide spectrum of industries. The range comprises four size classes: compact loaders, stereoloaders, mid-sized wheel loaders and XPower wheel loaders – all of which can be seen in action at Bauma 2025.

Crawler dozers and crawler loaders at Bauma 2025

Always tap into the full power. Whether for difficult thrust applications or precise levelling: with Liebherr crawler dozers, you are always one step ahead. The hydrostatic travel drive always delivers the optimum feed speed. Driver assistance systems guarantee maximum levelling quality and efficiency.

Telescopic handlers at Bauma 2025

Discover the world of Liebherr telescopic handlers. With groundbreaking innovations and state-of-the-art technologies, the telescopic handlers are raising the benchmark in the construction and industrial sectors. Whether lifting heavy loads or reaching great heights, the Liebherr telescopic handlers impress with their versatility and mobility.

Material handling machines at Bauma 2025

We present two innovative handling machines with electric drive that have been developed especially for port handling. Zero-emission, low-noise and economical – with cab elevations, modular undercarriage solutions and diverse equipment combinations and attachment tools that offer maximum efficiency for bulk goods and cargo.

Attachments at Bauma 2025

Experience the latest innovations and new products in the field of attachments and quick-coupling systems for earthmoving and material handling machines.

-screen_w736.webp)

.webp)

-screen_w736.webp)