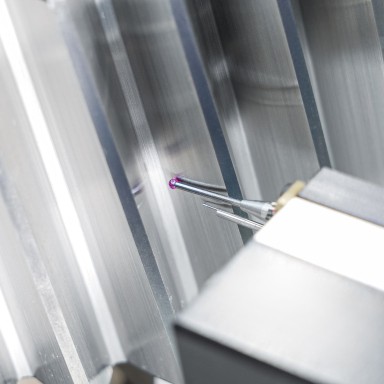

Newly developed free-moving probe

When it comes to aviation, top quality is essential – for every single component. For surface quality measurement, Liebherr-Verzahntechnik GmbH is the only manufacturer to offer a solution for internal and external gears on its measuring devices – optionally with skid or free-moving probe – in a single workpiece clamping.