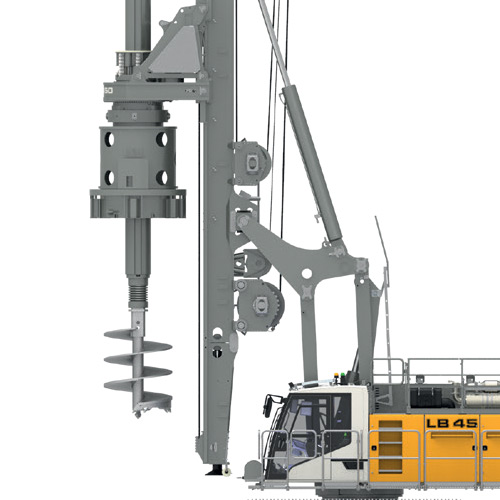

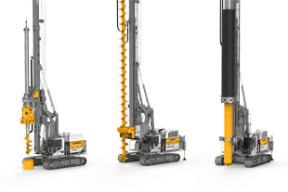

LB 45.1

Drilling rig (LB series)

With the LB 45.1, Liebherr presents its successor to the proven drilling rig LB 36-410. Its torque is 450 kNm – a 10 % increase in comparison to its predecessor. Various methods such as Kelly drilling, continuous flight auger drilling, partial and full displacement drilling or double rotary drilling can be applied. Despite of its large machine class the upper carriage is compact and designed for small working radii. This allows for working at jobsites with limited space.

Operating weight - 115.5 - 133.2 t

115.5 - 133.2 t

Max. torque - 450 kNm

450 kNm

Kelly drilling, max. drilling depth - 95.0 m

95.0 m

Kelly drilling, max. drilling diameter - 4,500 mm

4,500 mm