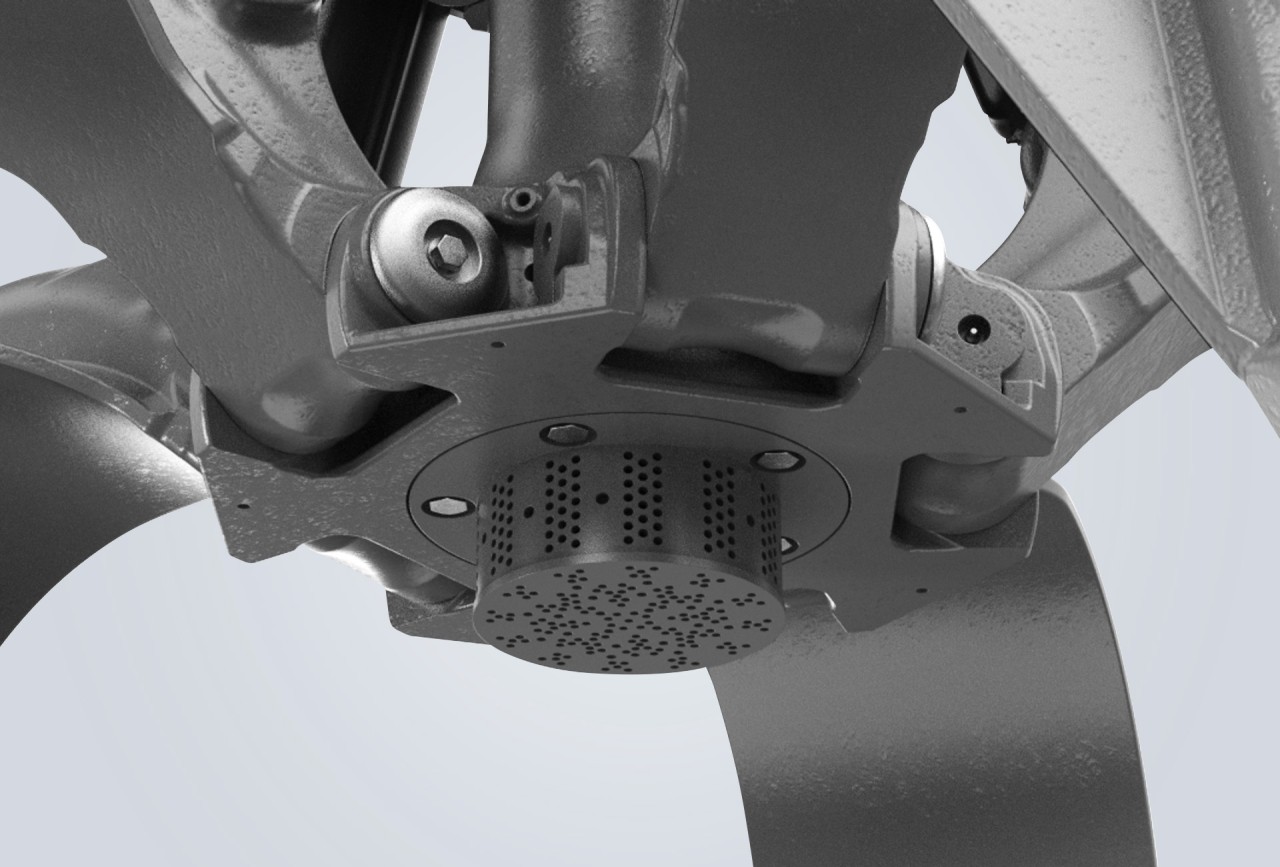

The new GMM 35 and GMM 50 multi-tine grabs

Not revised and modified, but a completely new development with a smart design. A game changer all the way down the line, which palpably changes the harshest requirements in scrap handling. Experience a completely new Liebherr multi-tine grab product - the unique GMM 35 and GMM 50 grab.

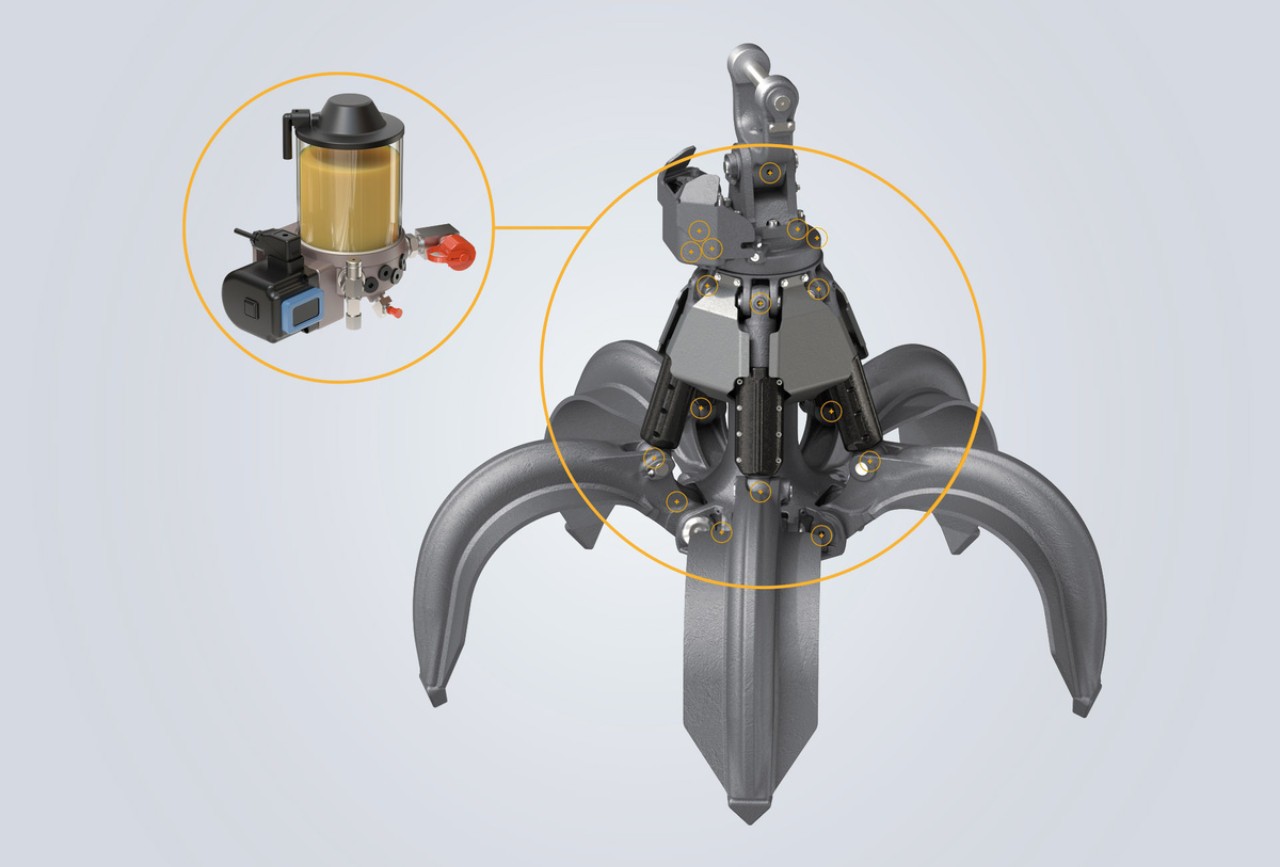

This orange peel grab was not just developed for our customers, but primarily in partnership with our customers. Their everyday, long experience in using this equipment together with decades of Liebherr expertise in grab production raises our development and production of grabs to a whole new level. The result of this intense collaboration is that the new GMM 35 and GMM 50 multi-tine grab delivers extraordinary capacity, incredible strength and an extremely lengthy service life. And these superlatives have not happened by chance. The use and targeted selection of very high quality materials combined with the sophisticated interplay of the various components provide the guarantee for the unrivalled durability, stability and strength of this grab.

A wide range of shell designs and versions and a broad selection of options give our customers the opportunity and flexibility to handle a very wide range of materials in the recycling and scrap industries in extremely harsh, challenging conditions efficiently and economically.

Contact us

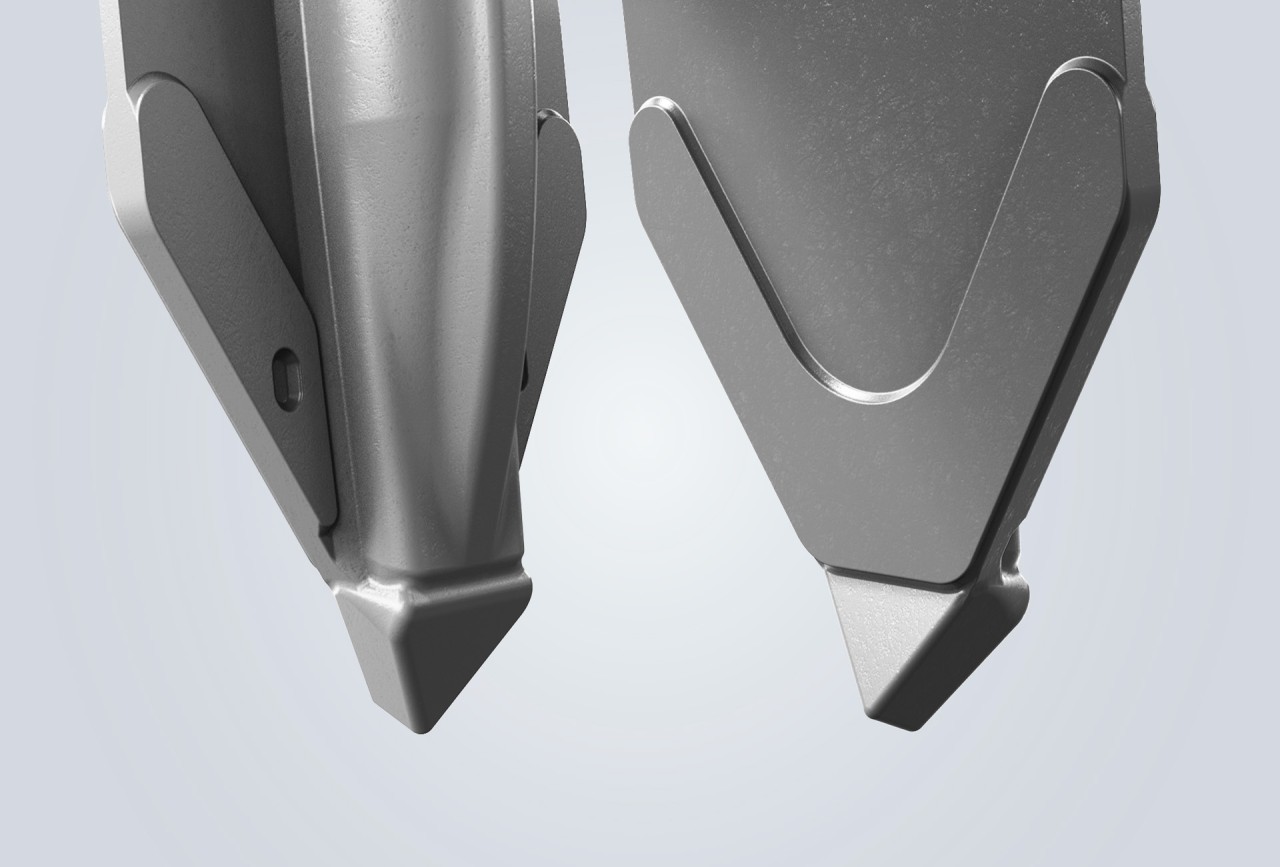

Tine versions and shapes

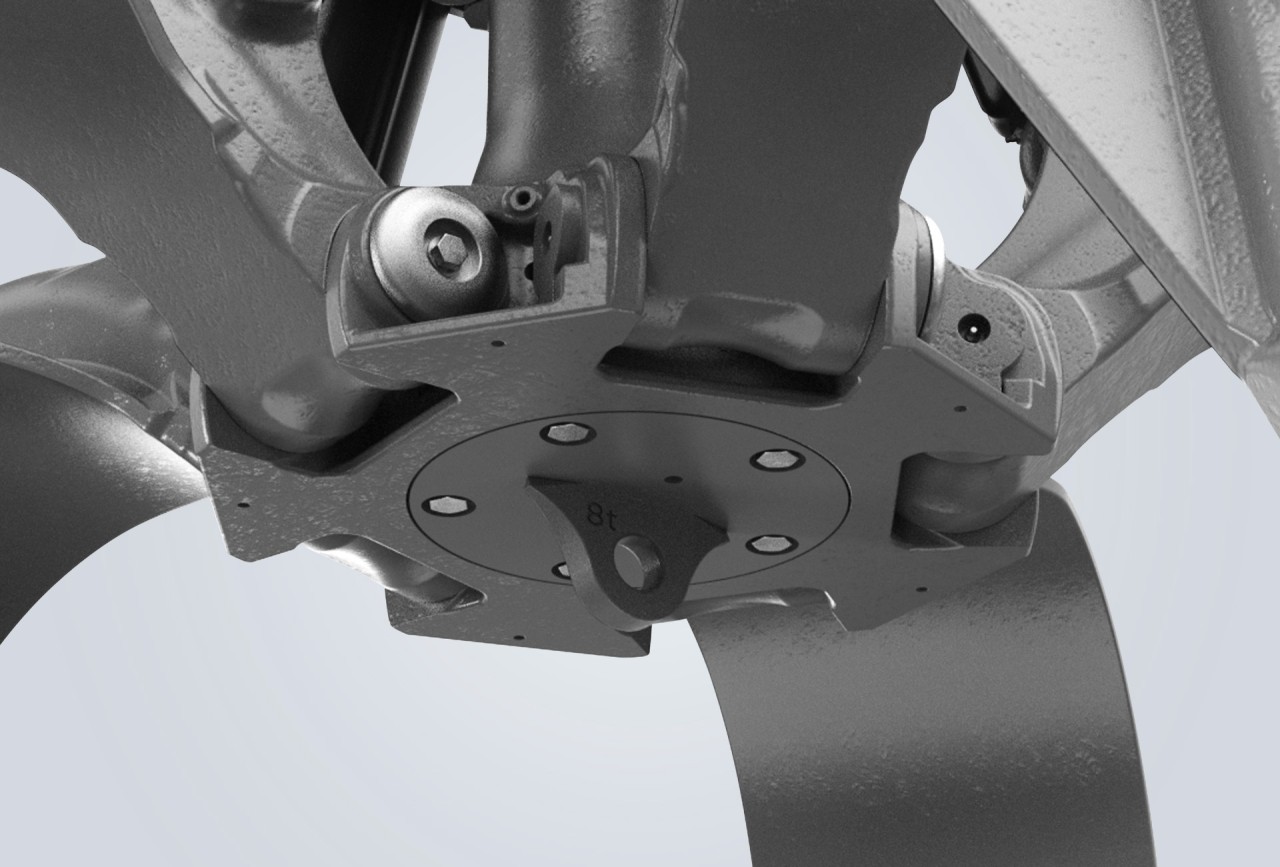

There is an extensive portfolio of tine shapes and capacities available for the efficient, economical handling of scrap and recycling material. This is perfectly tailored to the specific, individual customer use and the material being handled.

The grab version with five tines has been specially developed to ensure the best possible handling of mixed and shredded scrap or also chippings. The arrangement and shape of the tines has been improved to ensure perfect penetration and holding of bulky yet loose material.

Three perfectly designed tine shapes are available for handling a very wide range of recycling materials:

Open tines

For handling large, bulky scrap

Semi-closed tines

For handling medium-sized, mixed materials and sheared scrap

Closed tines, heart shape

For handling small, fine-grain materials and chippings